Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Benefits

TUBALL™ MATRIX only requires an ultra-low dosage starting from just 0.1 wt.%;

Allows production of conductive parts that retain bright colors;

Maintains or even increases mechanical strength;

Ensures permanent and uniform electrical conductivity without “hot spots”;

Without a significant increase in viscosity or density of the host material.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Applications

Anti-static SMC/BMC composites;

Conductive gelcoats;

Anti-static fuel tanks and pipes;

Electrostatic discharge materials applied by coil coating;

Other applications where electrical conductivity is required.- Dilution

In order to obtain a high-quality TUBALL™ MATRIX dispersion, OCSiAl recommends that close attention be paid to the dilution procedure. Refer to the Processing Guidelines for detailed information.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density (20°C) | 1.09 | g/ml | ASTM D4052 |

| Flash Point | min. 150 | °C | ASTM D3278 |

Technical Details & Test Data

- Typical Chemical Properties

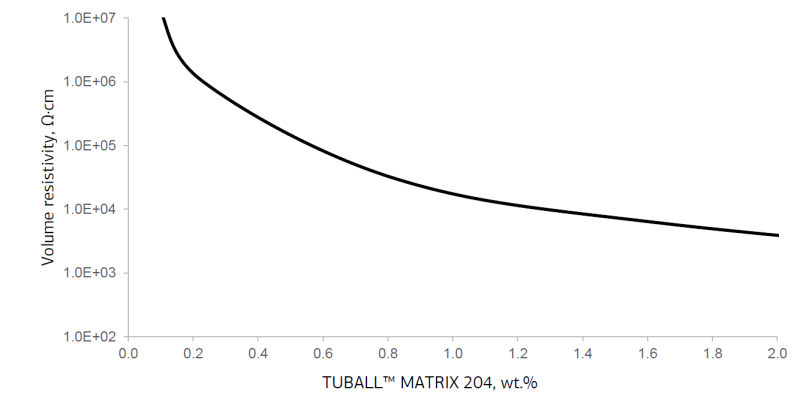

Depending on the characteristics of the dilution polymer and the processing conditions, the loading range of TUBALL™ MATRIX 204 for anti-static or dissipative applications can be as low as 0.1–4.0 wt.% calculated based on non-volatile matter. The exact loading level depends on the required performance, resin characteristics, processing conditions and presence of other ingredients. An example of a percolation curve, obtained by compounding TUBALL™ MATRIX 204 in TH-110 nonpreaccelerated bisphenol A vinyl ester resin, is shown in the figure below. The dilution of the concentrate in TH-110 was performed using a mechanical overhead stirrer.

Safety & Health

- Safety

To ensure safe handling, the appropriate safety regulations should be observed. OCSiAl recommends that every user should be able to apply the safe handling procedures necessary for the user’s applications before any handling or manufacturing takes place. A Material Safety Data Sheet outlining the hazards and handling methods for TUBALL™ MATRIX 204 is available.

Packaging & Availability

- Packaging

OCSiAl provides TUBALL™ MATRIX 204 samples in plastic containers (50 g concentrate). Industrial volumes are available in different packaging up to 50 kg.

Storage & Handling

- Storage and transportation

The product is stable in unopened original packaging when stored at temperatures between 5C and 40C. The recommended storage life is up to 24 months when stored as directed.