Knowde Enhanced TDS

Features & Benefits

- Benefits

• TUBALL™ SWCNT, carried by TUBALL™ MATRIX, enable ultra-low dosage of conductive filler starting

from just 0.03 wt.% for anti-static, static dissipative and conductive applications

• Allow production of conductive parts that retains bright colors

• Ensure permanent and uniform electrical conductivity without “hot spots”

• Maintain rheology of the uncured compound

• Standard processing and mixing equipment

• Improve mechanical properties and retain softness- Warranties and disclaimer

The Products correspond to the chemical composition indicated in the Technical Data Sheet and the Safety

Data Sheet supplied with the Product. The information contained in this document (Information) is based on

trials carried out by OCSiAl and may contain inaccuracies or errors that could cause injury, loss or damage.

OCSiAl gives no further warranty and makes no further representation regarding the Products and/or the

accuracy of Information and/or suggestions for any particular use of the Products or Information, or that

suggested use will not infringe any patent. The Products and Information are supplied on an “as is” basis.

These express provisions are in place for all warranties, representations, conditions, terms, undertakings and

obligations implied by statute, common law, custom, trade usage, course of dealing or otherwise (including

implied undertakings of satisfactory quality, conformity with description, fitness for purpose and reasonable

skill and care), all of which are hereby excluded to the maximum extent permitted by applicable law.

Applications & Uses

- METHOD OF ADDITION

To enable the development of a well-distributed network of percolating TUBALL™ nanotubes in the silicone

matrix, a compounding step of the concentrate is essential.

TUBALL™ MATRIX 602 can be diluted into compounds through the use of standard silicone compounding

equipment. Other approaches for masterbatch dilution may be used provided that their mixing efficiency is

sufficient. More information about the key parameters for masterbatch dilution and compound processing

can be found in the “Processing Guidelines for TUBALL™ MATRIX 601/602 for Liquid Silicones- TYPICAL DOSAGE LEVEL

The concentration of TUBALL™ MATRIX 602 that is required in the final compound should be determined

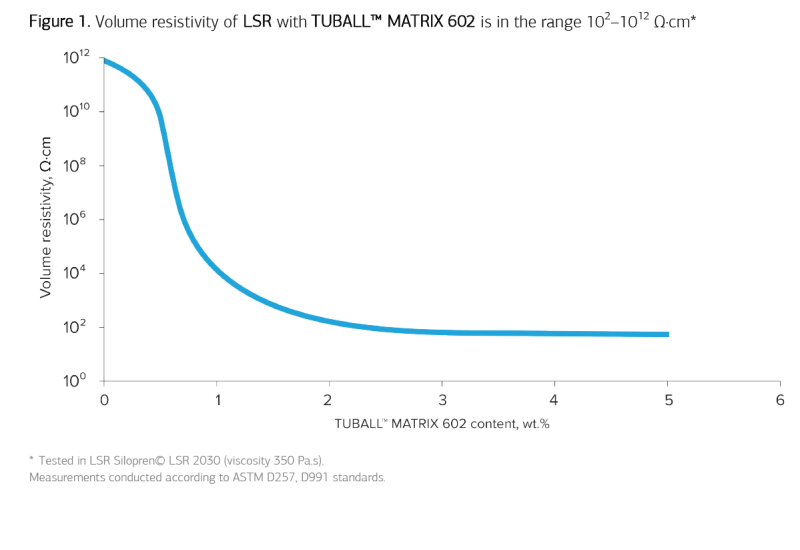

according to the desired level of conductivity, as shown in Figure 1 for LSR.

The loading required to obtain a specific conductivity can vary by type of silicone, by the final formulation and

by the type of application/molding process.

It is also important to note that the required dosage level of TUBALL™ MATRIX refers to the whole system.

For example, if the system consists of 50% part A and 50% part B, and the required level of volume resistivity

in liquid silicone is 104 Ω·cm, the required TUBALL™ MATRIX concentration should be 1 wt.% for the whole

system (Figure 1).

For more information refer to the Processing Guidelines.

Properties

- Appearance

- Black paste

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Concentrate Carrier | Vinyl-terminated polydimethylsiloxane | - | - |

| Density (20°C) | Approx. 1.02 | g/cm³ | DIN 51757 |

| Vinyl Groups | 0.36 | mmol/g | - |

Safety & Health

- Safety

To ensure safe handling, the appropriate safety regulations should be observed. OCSiAl recommends that

every user should be able to apply the safe handling procedures necessary for the user’s applications before

any handling or manufacturing takes place. A Safety Data Sheet outlining the hazards and handling methods

for TUBALL™ MATRIX is available.

Packaging & Availability

- Packaging

Plastic or metal cans (0.2, 0.5, 1, 5, 10 kg).

OCSiAl provides TUBALL™ MATRIX 602 test samples in plastic cans (50, 100 or 200 g concentrate).

Storage & Handling

- STORAGE AND TRANSPORTATION

The product is stable in its unopened original packaging when stored under normal temperature conditions.

The recommended storage life is up to 24 months when stored as directed.