Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Superiority

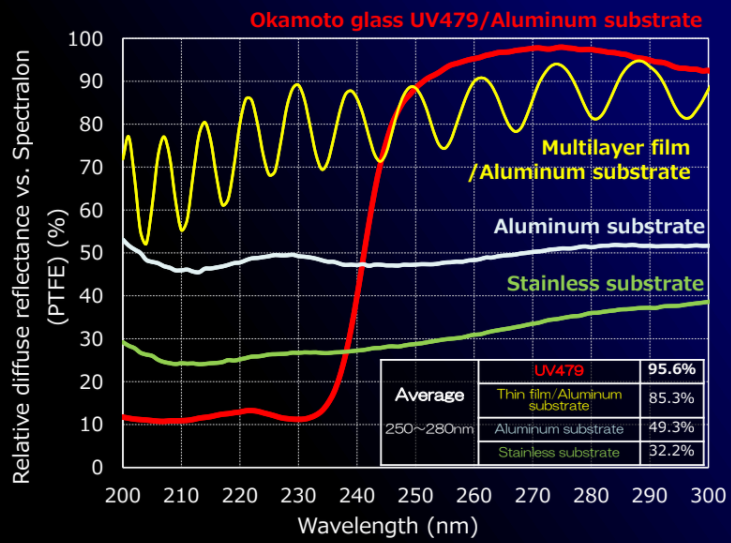

- In the UV-C band region (250 to 280 nm), about twice as high reflectance as

aluminum substrate (UV479: 95.6% / Aluminum substrate : 49.3%) - High durability allows operation even at high output

- Our products enable customers to apply for complexity in shape.

- In the UV-C band region (250 to 280 nm), about twice as high reflectance as

Applications & Uses

- Markets

- Applications

- Application Method

- Cure Method

- Plastics & Elastomers End Uses

- Applications

- LED COB UV reflection coat

- Medical equipment, home appliance with UV sterilization unit

- Air cleaner with UV sterilization unit

- Typical Use

- Highly reflective COB / SMD substrate

- Higher output of UV sterilization / disinfection equipment

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Adhesives | Al / SUS | — | — |

| Breakdown Voltage (Thickness 47μm on Al) | 3.2 | KV | 10sec / Electrode distance 20mm |

| Coating Method | Screen printing | — | — |

| Coating Method | Spray | — | — |

| Insulation Resistance (Thickness 47μm on Al) | 1.7×10^9 | Ω | 500V / 10sec / Electrode distance 20mm |

| Reflection (at 265nm, Thickness 30μm or more) | min. 90 | % | Reflectance is relative comparison with Spectralon® (Porous PTFE) |

| Viscosity (at 10 rpm, Screen printing) | 10 - 70 | Pa.s | Viscosity can be adjusted by the customer coating conditions. |

| Viscosity (at 10 rpm, Spray) | 10 - 30 | Pa.s | Viscosity can be adjusted by the customer coating conditions. |

Technical Details & Test Data

- Technical Information

- UV sterilization is expected as the valuable technology to disinfect bacterial, virus thereat around us.

- High efficient reflection coating for UV wavelength 250~400nm.

- Thermal curing ink (main + agent) for screen printing, also we can provide printing service too.

- Reflection UV479 : min. 90% @265nm

- Endurance:

Thermal R change within <5% at 200℃/2000hours

High temp & humidity R change within <5% at 60℃-90%/2000hours

UV resistance R change within <5% at 26mW/cm2, 270nm/2000hours

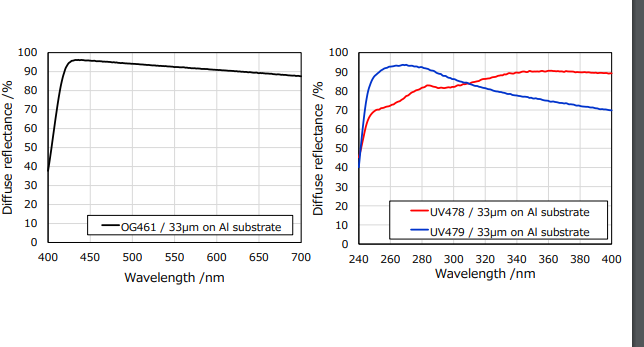

Reflectance

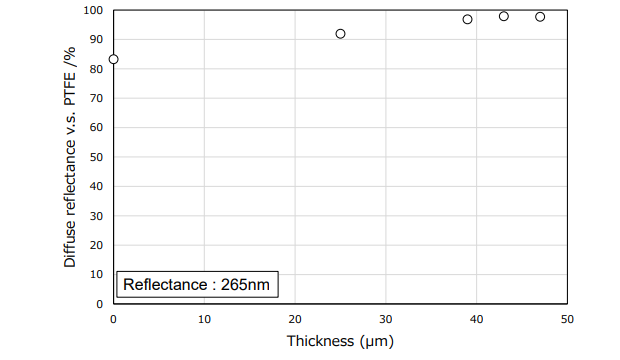

Thickness Dependence

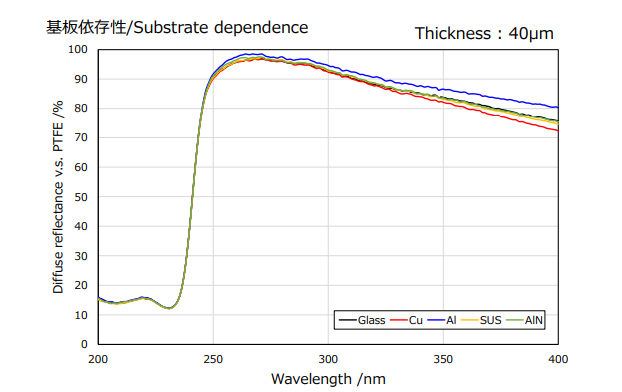

Substrate Dependence

Substrate Dependence

- Comparison of Reflection Characteristics in UV-C Area

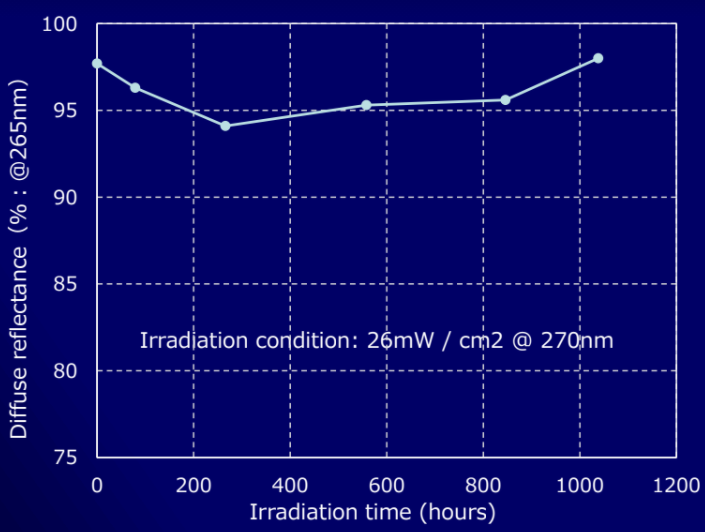

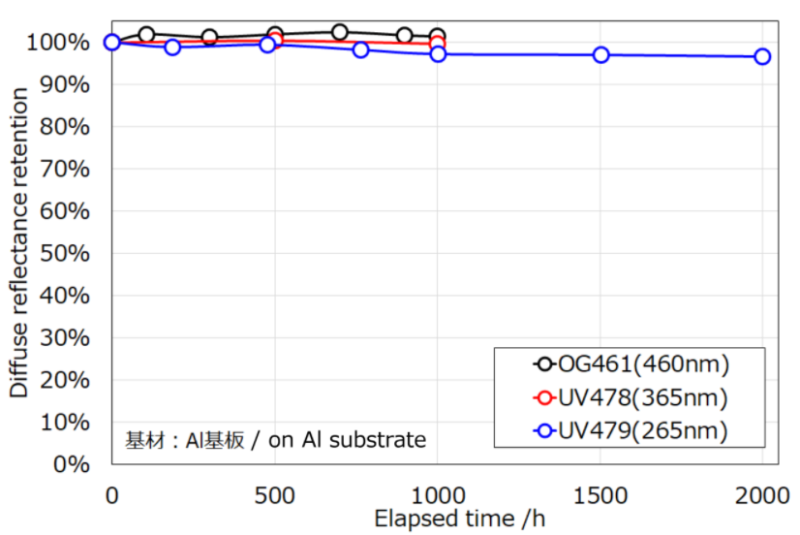

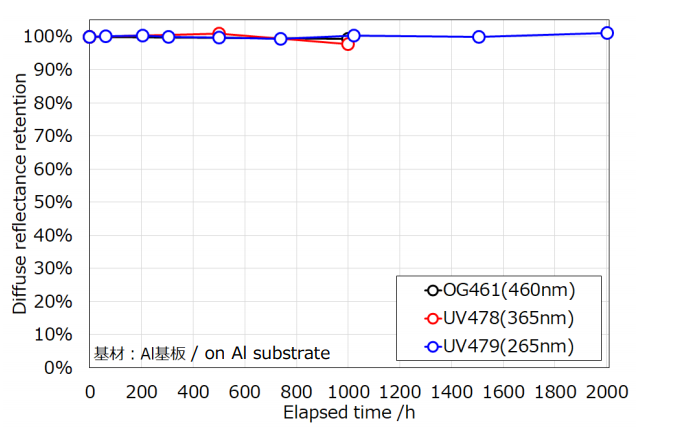

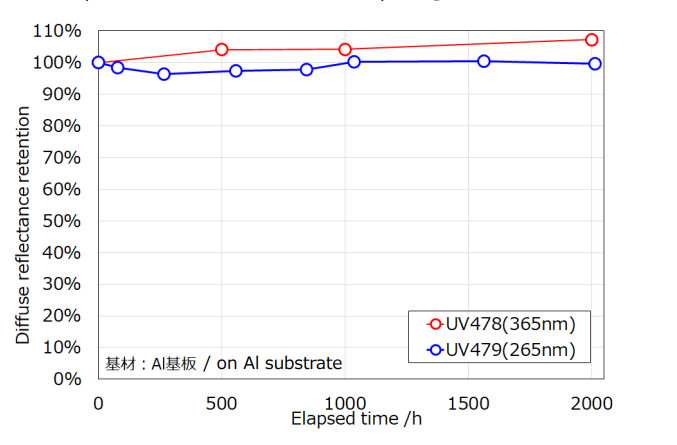

- UV Durability Test Result

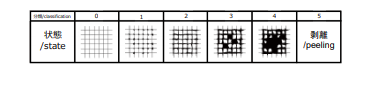

- Durability Evaluation Example

Test item Test condition Result Heat resistance

test200°C

×1,000 hoursNo decrease in

reflectance

more than 5%Constant

temperature and

humidity test60°C/90%

×1,000 hoursCycle test 25°C↔260°C

10 cyclesNo peeling or

discoloration- Mixing and Curing Conditions

Mixing

ratioMaterial Concentration Main material (UV479) 100wt% Curing material (OG840) 2.0wt% Note: Adjust the viscosity with diluent if necessary.

Curing Process Apparatus Temperature Retention time Drying Box oven / Belt dryer 90°C 10 min. Curing 180°C 180 min. Note: The dryer should be well ventilated.

Make sure that the surface is sufficiently dry

when you touch it with your finger.

Please cure until you feel it.- High Temperature Resistance

Holding Temperature : 200°C

- Weatherability

Holding Condition : 60°C 90%RH

- UV-C resistance

Irradiation Condition: 26mW/cm2@270nm

- Adhesive

- Cross Cut Test before and after Thermal shock test

- Thermal shock test condition : 260°C→25°C water × 10times

UV479

before/afterAl 0/0 Cu SUS 0/0

- Recommended Blending Conditions

Blending condition

Blend Ratio

- Main Body : UV479 = 100 wt%

- Curing Agent OG840 for UV479 = 2.0 wt%

- Pick Main Body up from the refrigerator

- And Keep it in the room and store until main body up to room temperature (>6 Hours) as unopened (Avoid Dew condensation)

- Curing Agent solution should NOT be in the refrigerator.

Thinner

- In case it need to adjust viscosity

Storage condition

- Main Body : OG461, UV478, UV479) = 5°C (Refrigerated storage below 5°C)

Shelf Life: 3 Months after manufacturing - Curing Agent : OG830, OG831, OG840 = Room Temperature

Shelf Life : 6 Months after manufacturing

- Recommended Curing Conditions

Drying Condition

- 90°C for 10 min in the Box Oven or Equivalent Heat amount of Belt dryer

Curing Condition

- UV479 : 180°C for 120~180 min(minimum) in the Box Oven or Equivalent Heat amount of Belt dryer

- Feel dry surface by the finger touch is good enough in the above condition