Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Basis

- Thixotropic Paste

- Consistency

- Non-Slump Paste

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Benefits

- High movement capability.

- Excellent adhesion to a wide range of substrates without priming.

- Extremely long service life.

- Resistant to vibrations.

- For inside and outside.

- Suitable for cold climates.

- Paintable.

Applications & Uses

- Markets

- Application Method

- Fields of Applications

- OLIVE PU-16 adheres to most of the materials used in construction, such as concrete, stone, ceramics, glass, aluminum, wood, polyester, etc.

- OLIVE PU-16 it's used as a sealing product in construction field, for vertical and horizontal expansion joints, concrete walls, prefabricated walls, etc.

- Direction for Use

Surface preparation and sealant application:

Cleaning and joint preparation

Substrates (joint flanks) must be clean, dry, and free of dust, grease and other contaminant which may affect the adhesion. Non- porous surfaces (such as aluminum, glass, etc.) should be cleaned with a suitable solvent and thoroughly dried with a clean cloth. Porous substrates (such as concrete, brickwork, etc.) must be mechanically cleaned from loose particles. Mask off the joint edges.

Primer

OLIVE PU-16 adheres to most common construction materials without primer. However, a preliminary adhesion test is recommended on every surface. Sometimes, it may be necessary to treat the joint surfaces with a primer to obtain better adhesion performances. Please contact us for technical assistance.

Inserting backing material

Use the closed cell polyethylene backer foam OLIVE CORDON CELULAR as a back-up material to limit the sealant joint depth and avoid the sealant to adhere to the joint base. Choose the right backing strip diameter (at least 25% wider than the joint width).

Sealant applications

After substrate preparation, apply the sealant with a professional caulking gun, evenly and without bubbles. 0bserve the eventually used primer's open time before filling the joint.

Tooling and finlshing

The joint should be tooled and smoothed before skin formation. Press the sealant and smooth it ensuring good contact with the surfaces to seal. Use neutral soapy water as a tooling agent. Remove masking tape. Uncured product may be easily removed with solvents. Cured sealant must be removed mechanically.Remarks

- For difficult materials, including plastics such as PVC, ABS, PMMA, or materials such as aluminum and lacquered metal it's recommended to perform preliminary adhesion test in order to determine the adherence.

- It's compatible with water based paints. In solvent paints a preliminary test is recommended. It doesn't stain the marble or granite stone.

- This product must be used within 24 hours after the cartridge opening; otherwise, the sealer could cure inside. Do not apply at temperatures below 5°C.

- Avoid any contact with non-cured Ms, hybrid PU or silicone sealants as well as with alcohols or ammonia during curing.

- Do not use 0LIVE PU-16 on bituminous substrates or on building materials which might bleed oils, plasticizers or solvents. (e.g. natural rubber, chloroprene, EPDM).

- There is no adhesion to PE, PP, PTFE (Teflon®). Due to the wide variety of possible substrates, we recommend a preliminary compatibility test.

- Not intended for structural glazing.

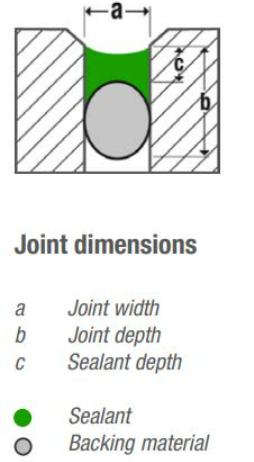

- Joint Design

Expansion joints should be correctly dimensioned taking account of dimensional changes in the substrates due to thermal filuctuations. Joint's dimensions should match with the sealant movement capability, with a maximum permitted value of 25%

Use closed cell polyethylene backer foam (Olive Backer Rod) as a back-up material to

limit the sealant joint depth and avoid three-sided adhesion.

The following general rules/recommendations should be followedGeneral statement: The ideal joint has a 2:1 width: depth ratio

Minimum joint dimensions 5-6mm width x 5-6 mm depth.

Up to 12 mm wide: Width = depth From 12mm to 24mm wide Depth = ½ width Wider than 24mm Depth = 12-15mm

Expansion joints should not be wider than 50mm

Properties

- Physical Form

- Physical Properties

- Mechanical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Specific Gravity | approx. 1.12-1.18 | g/ml | ISO 2811-1 |

| Value | Units | Test Method / Conditions | |

| Hardness | approx. 25 | Shore A | ISO 868 |

| Tensile Strength (12x12x50 mm joint, 28 days, 23°C: 50% H.R.) | 0.4 | Mpa | ISO 8339 |

| Tensile Elongation at Break (12x12x50 mm joint, 28 days, 23°C: 50% H.R.) | min. 400 | % | ISO 8339 |

| Value | Units | Test Method / Conditions | |

| Skin Forming Time (23°C, 50% R.H.) | approx. 90-150 | Minutes | OQ.16-internal |

| Curing Rate | approx. 3 | mm/24 h | OQ.18-internal |

| Resistance to Acids | Medium | — | — |

| Resistance to UV | Good | — | — |

| Loss of Volume | max. 3 | mm | ISO 10563 |

| Tear Strength | approx. 6.5 | N/mm | ISO 34 |

| Total VOC Content | approx. 67 | g/l | SCAQMD rule 1168 |

| Application Temperature | 5-35 | ºC | — |

| Service Temperature | -40 to +80 | ºC | — |

Regulatory & Compliance

- Product Certifications

Olive PU-16 meets the following specifications:

- SNJF certified, (Façade). Class 25E

- ISO 11600-F-25LM

- CE marking: EN 15651-1 F-EXT-INT-CC

- Environmental Regulations

- French VOC-emission class A+.

- Conforms to LEED® IEQ-credits 4.1 (Indoor Environmental Quality) adhesives and sealants.

Safety & Health

- Safety

Use in well-ventilated areas, avoiding contact with skin and eyes. Keep out of the reach of children. Information relating to the safety of the product is available on the safety data sheet (SDS) Before using the product, we advise you to carefully read the SDS and the safety labels.

Packaging & Availability

- Packaging Type

- Packaging Information

This product is available in 300ml cartridges and 600ml sausages. Other packaging is available under request.

Storage & Handling

- Storage

The shelf life is 12 months in its unopened original packaging, in dry conditions and protected from direct sunlight at temperatures between +5ºC and +25ºC.