Knowde Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Compatible Substrates & Surfaces

- Coating Type

- Applications

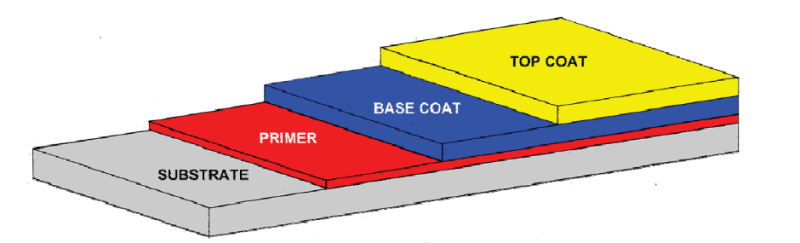

Application of Trapylen® 6700 W as primer

In this application Trapylen® 6700 W is applied just as a resin solution without modification with other binder resins. Trapylen® 6700 W can be applied by dip- coating, spraying gun or by the tampon printing method.

Recommended solids content for application:

- resin solution 5 %

- waterbased dispersion 10 %

Recommended coating weight, calculated on solids:

3...5 g/m2. An increased coating weight can cause cohesive failures of the primer layer due to low molecular weight of Trapylen® 6700 WDrying:

Drying condition of 30 s at 80...100 °C are suffici ent for film forming of Trapylen® 6700 W before application of the base coat or top coat. A drying temperature above the softening point of Trapylen® 6700 W is recommended in order to achieve the best results in terms of adhesion strength. Typical drying condition for coating automotive bumpers is 30 mins at 80 °C.

Properties

- Soluble in

- Water

- Typical Properties

- Chemical Composition

- Application Properties

| Value | Units | Test Method / Conditions | |

| Chlorine Content | 22.0 | % | - |

| Value | Units | Test Method / Conditions | |

| Solid Content | 30.0 | % | - |

| Value | Units | Test Method / Conditions | |

| Solid Content (resin solution) | 5.0 | % | - |

| Solid Content (waterbased dispersion) | 10.0 | % | - |

Packaging & Availability

- Regional Availability