Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Need Fuel Resistant Nitrile Seals

Parco is committed to being the leader in competitively priced fuel resistant seals. Seals made from Parco’s 0228-70 compound meet the critical requirements of the motor vehicle industry to ensure vehicle safety and performance.

- 0228-70 Meets Your Needs

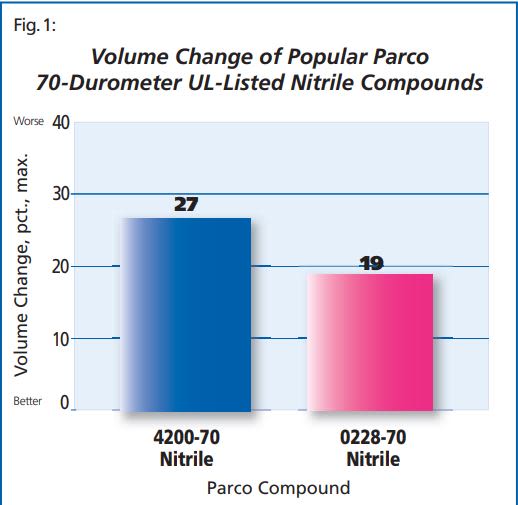

Outstanding Resistance to Fuels Parco’s 0228-70 seals offer excellent performance in low alcohol fuel applications. Fuel may cause seals to swell significantly. Our 0228-70 seals had volume swell of only 19 percent after 70 hours at 73°F in Fuel B.

UL-listed Parco’s 0228-70 seals are listed by Underwriter’s Laboratory (UL) 157 for end-use applications in gasoline/alcohol blends. UL tests and certifies certain products to ensure the safety of end-use applications.

- Product Highlight

Because nitriles are versatile and inexpensive, they are the most popular industrial seal material. Nitrile compounds are copolymers of acrylonitrile and butadiene. Acrylonitrile provides resistance to petroleum based fluids, such as oil and fuels. Butadiene contributes low-temperature flexibility. Standard nitrile is also known as Buna N. Nitrile compounds perform well in gasoline, crude oil, power-steering fluid, hexane, toluene, water, water-based hydraulic fluids, and dilute bases, such as sodium hydroxide. Because nitriles contain unsaturated carbon-carbon bonds in the base polymer, they are not suitable for exposure to ozone, sunlight, and weathering.

- Key Features

• Wide range of service temperatures: Parco 0228-70 seals are suitable for applications ranging from -40 to +200°F.

Applications & Uses

- Applications

- Cure Method

- Plastics & Elastomers End Uses

- Chemical Resistance

USE WITH DO NOT USE WITH - Ammonia

- Diester Synthetic Lubricants

- Gasoline

- Naphtha

- Propane

- Automatic Transmission Fluid

- Hot Air

- Ultraviolet Light

Properties

- Chemical Resistance

- Color

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Hardness | 66.0 | Shore A | D2240 |

| Tensile Strength | 1924.0 | psi | D412 |

| Ultimate Elongation (pct) | 347.0 | — | D412 |

| Modulus (100 pct, Elongation, pct) | 620.0 | psi | D412 |

| Compression Set Solid 22 hours (100°C, 212°F ) Pct of Original Deflection | max. 10 | — | D395 |

| Heat Aging 70 hours (100°C, 212°F) Hardness Change, pts. | 2.0 | Shore A | D573 |

| Heat Aging 70 hours (100°C, 212°F) Tensile Strength Change, pct. | 10.0 | — | D573 |

| Heat Aging 70 hours (100°C, 212°F) Ultimate Elongation Change, pct. | max. -17 | — | D573 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Hardness Change, pts. | -14.0 | Shore A | D471 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Tensile Strength Change, pct. | -14.0 | — | D471 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Ultimate Elongation Change, pct. | -25.0 | — | D471 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Volume Change, pct. | 19.0 | — | D471 |

| Low Temperature Flexibility TR-10 | -34(-30) | °C(°F) | D1329 |

| Low Temperature Flexibility Glass Transition (Midpoint) | -35(-31) | °C(°F) | D1329 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

*High temperature limit is based on requirements in MIL-P-25732 and AMS-P-83461- Technical Details

1.Volume change calculated after 70 hours at 23°C (73°F) in ASTM Reference Fuel B.

1.Volume change calculated after 70 hours at 23°C (73°F) in ASTM Reference Fuel B.

Source: Parco Test Reports. Parco seals made from 0228-70 have excellent resistance to fuels. At 19 percent, 0228-70 outperforms our most popular general-purpose UL-listed 70-durometer nitrile compound.