Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- 4200-70 Meets Your Needs

Excellent Physical Properties

Parco’s 4200-70 70-durometer nitrile O-rings have excellent physical properties (see test report on reverse side). For nearly 40 years, 4200-70 O-rings have been used in a wide variety of applications with great results. So when you specify 4200-70, rest assured that you’ve made the right choice.

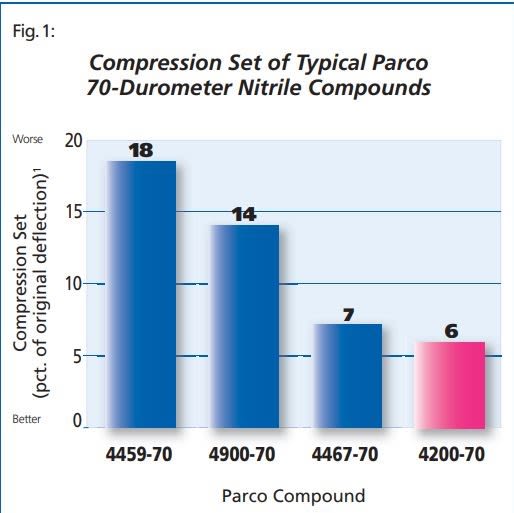

Excellent Resistance to Compression Set

To perform properly, seals must resist taking a set from compression after being installed. When a seal takes a set, it no longer exerts force on the mating surfaces, resulting in leakage. A compound with low compression set, like 4200-70, better maintains its elastomeric properties and original thickness, preserving seal integrity. Seals made from Parco’s 4200-70 compound provide excellent resistance to compression set. After testing 4200-70 for 22 hours at 212°F, it had a compression set of only 6 percent.

Very Good Resistance

to a Variety of Fluids Nitrile compounds, like 4200-70, provide very good service in gasoline, crude oil, power steering fluid, hexane, toluene, water, water-based hydraulic fluids, and dilute bases such as sodium hydroxide.

- Need General-Purpose Nitrile Seals

Parco is committed to being the leader in generalpurpose nitrile seals. Because nitriles are versatile and inexpensive, they are the most popular industrial seal material. More than 50 percent of sealing needs can be met using nitrile.

Applications & Uses

- Applications

- Cure Method

- Plastics & Elastomers End Uses

- Chemical Resistance

USE WITH DO NOT USE WITH - Automatic Transmission Fluid

- Crude Oil Carbon

- Gasoline Ethyl

- Propane

- Water

- Acetone

- Tetrachloride

- Acetate

- Nitromethane

- Toluene

Properties

- Color

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Hardness | 70.0 | Shore A | D2240 |

| Tensile Strength | 2385.0 | psi | D412 |

| Ultimate Elongation (pct) | 363.0 | — | D412 |

| Modulus (100 pct, Elongation, pct) | 617.0 | psi | D412 |

| Compression Set Solid 22 hours (100°C, 212°F ) Pct of Original Deflection | max. 13 | — | D395 |

| Heat Aging 70 hours (100°C, 212°F) Hardness Change, pts. | 4.0 | Shore A | D573 |

| Heat Aging 70 hours (100°C, 212°F) Tensile Strength Change, pct. | 6.0 | — | D573 |

| Heat Aging 70 hours (100°C, 212°F) Ultimate Elongation Change, pct. | max. -20 | — | D573 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Hardness Change, pts. | -11.0 | Shore A | D471 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Tensile Strength Change, pct. | -39.0 | — | D471 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Ultimate Elongation Change, pct. | -41.0 | — | D471 |

| Fluid Aging, Fuel B 70 hours (23°C, 73°F) Volume Change, pct. | 28.0 | — | D471 |

| Low Temperature Flexibility TR-10 | -28(-19) | °C(°F) | D1329 |

| Low Temperature Flexibility Glass Transition (Midpoint) | -26(-15) | °C(°F) | D1329 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Details

*High temperature limit is based on requirements in MIL-P-25732 and AMS-P-83461- Technical Details

1.Compression set calculated after 22 hours at 100°C (212°F).

Source: Parco Test Reports

Parco seals made from 4200-70 have excellent resistance to compression set. At 6 percent, 4200-70 outperforms other 70-durometer nitrile compounds.