Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

Phygen PVD technology allows deposition of a wide variety of coatings (metals, alloys, and compounds). One example is Phygen’s new FortiPhySM Chromium Nitride coating, which exhibits extreme hardness and toughness superior to that of the best conventional PVD-based coating. Phygen’s PVD surface coating technology provides a combination of superior coating properties by creating a dense, non-columnar coating structure having the highest possible adhesion level.

Coating microstructure is precisely controlled by Phygen's process parameters. As a result, FortiPhy high performance surface coating constitutes a single-phase, stoichiometric, nanocrystalline chromium nitride having a dense, highly textured structure. The fine-grained structure and high cohesive strength of Phygen chromium nitride coatings permit deposition of extremely tough and hard coatings with much higher abrasive wear resistance than provided by conventional PVD processes.

Unlike hot-processed CVD (chemical vapor deposition) and TD (thermal diffusion) coatings, which combine with carbon molecules within the substrate to form a hard layer, FortiPhy is a chemically complete tool coating, applied to a surface using a special high-adhesion process.

Typical CVD and TD coatings are applied at temperatures above 1800°F in order to increase diffusion activity within the substrate. During the hot coating process, carbon atoms move to the surface and combine with the coating material to form a third compound. This can produce a hard coating but there are drawbacks. Only a limited amount carbon in the substrate is available to migrate to the surface, and it can travel only a short distance. This means that as tools and coatings wear, a second application of the coating usually lasts only about 70 percent as long as the first application. A third application generally will have a useful life that is only 30 percent as great as the original tool coating. After that, free carbon is all “used up.” When no additional carbon can be leached to the surface, the re-coating process ceases to provide any benefit. Furthermore, decarburization of the substrate weakens material near the surface, thereby increasing the likelihood of chipping.

FortiPhy hard surface coating does not require diffusion within the substrate to build a hard coating. Instead, the patented Phygen process, with its exceptional level of process control, applies a chemically stoichometric layer of nano-sized particles onto the surface. No carbon or other molecules are leached from the substrate. This means that every re-coat of FortiPhy tool and die coating has the same toughness and lasts as long as the first. More importantly, no decarburization or weakening of the substrate occurs. Tool life is extended, and chemical composition of the substrate remains unchanged, regardless of rework.

FortiPhy high performance surface coating is an industrial coating, not a decorative coating. However, its appearance may be enhanced, if necessary, by the addition of a TiN or other color overlay. While FortiPhy is primarily intended to reduce wear in severe stress and temperature applications, it also is highly corrosion resistant. In a recent test, a purposely substandard application of very thin and porous FortiPhy tool coating on mild steel provided significant protection by cutting the corrosion rate and by creating a passivity range with a pitting potential of more than 800mV. In the same test, a uniform coating of FortiPhy further decreased the corrosion rate by several orders of value. In real-world applications, FortiPhy provides unprecedented corrosion protection. In an injection mold, for example, a coating of FortiPhy provided a 600-percent increase in the life of mold vents that previously had been destroyed by caustic thermoplastic byproducts.

- Features

Phygen’s patented1 Physical Vapor Deposition (PVD) coating technology allows the deposition of extremely tough and hard coatings with much higher abrasive wear resistance than is provided by conventional PVD processes. The technology is based on principles of Plasma Acceleration and results in a higher plasma density and an intense low energy ion bombardment during the coating deposition. With Phygen’s environmentally-friendly PVD process, a wide variety of coatings (metals, alloys and compounds) can be adhered to virtually any substrate.

FortiPhySM Chromium Nitride coatings, deposited by Phygen’s PVD process, exhibit extreme hardness and toughness superior to the best conventional PVD-based coatings. Phygen’s technology provides a unique combination of coating properties by creating a thin and dense, non- columnar coating structure having the highest possible adhesion level to virtually any substrate material. The microstructure of the coating is controlled by precise process parameters and, as a result, the FortiPhy Chromium Nitride coating constitutes an exceptionally thin, single-phase, stoichiometric, nanocrystalline chromium nitride with a highly textured dense structure that maintains the critical dimensions of the coated tool or component.

- Benefits

- FortiPhy coatings are less brittle and tougher than conventional hard PVD coatings and may withstand much higher mechanical loads.

- The microhardness of the FortiPhy Chromium Nitride coating exceeds that of conventional PVD chromium nitride coatings.

- The combination of high hardness and toughness results in exceptional abrasive wear resistance.

- The coating possesses low friction properties (C.O.F. less than 0.1) under properly lubricated conditions in an oxidizing environment.

- The coatings are chemically and thermally stable in air up to 850º C (1550º F). The coatings are chemically inert and provide excellent corrosion resistance because of their dense, non-columnar microstructure.

- The thin but extremely wear resistant FortiPhy Chromium Nitride coating, deposited by using Phygen’s patented PVD process, results in virtually no change to critical dimensions of the coated tools or precise components.

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

Properties

- Physical and Mechanical Properties

- Physical and Mechanical Properties

- Crystal StructureFccMicrostructureNon-columnar equiaxially grained structure

| Value | Units | Test Method / Conditions | |

| Modulus of Elasticity | 400.0 | GPa | - |

| Knoop Microhardness (200g Load) | 3000 - 3500 | HK | - |

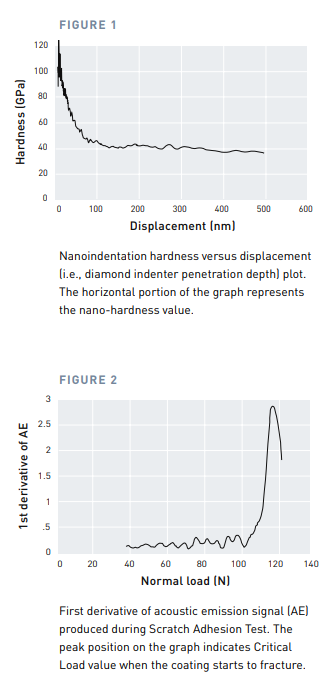

| Nanoindentation Hardness | 30 - 50 | GPa | - |

| Coefficient of Friction (Diesel Fuel Lubricated) | 0.09 - 0.12 | - | - |

| Coefficient of Friction (Dry Nitrogen) | 0.18 - 0.22 | - | - |

| Surface Roughness (Ra) | 40 - 70 | nm | - |

| Coating Wear Rate (100g, 440C Steel Ball) | 2x10⁻⁶ - 6.7x10⁻⁸ | mm³/N·m | Ball-on-disk test |

| Coefficient of Thermal Expansion (10⁻⁶, 20 - 800ºC) | 2.3 | per K | - |

| Coefficient of Thermal Expansion (10⁻⁶, 850 - 1040ºC) | 7.5 | per K | - |

| Scratch Test Critical Load (N) | 115 - 120 | - | - |