Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Usage Recommendations

- It is recommended that BOPP film should be tempered at operating room temperature for 24 hours before use

- Metalized films should be laminated because the metal layer is not resistant to scratches

- Before printing on metalized films, it is strongly recommended to apply a primer

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Average Thickness Deviation | 2.5 | % | - |

| Yield | 42.18 - 46.62 | m²/kg | - |

| Unit Weight | 21.37 - 23.62 | g/m² | - |

| Gloss (45°) | 81 - 85 | - | ASTM D 2457 |

| Haze | 1.8 - 2.2 | % | ASTM D 1003 |

| Dynamic Coefficient of Friction | max. 0.25 | - | ASTM D 1894 |

| Shrinkage (MD, 120°C, 5 min) | 2.0 | % | BMS TT 0.2 |

| Shrinkage (TD, 120°C, 5 min) | 2.0 | % | BMS TT 0.2 |

| Sealing Range | 118 - 145 | - | - |

| Elongation at Break (MD) | 400 - 600 | % | ASTM D 882 |

| Elongation at Break (TD) | 450 - 650 | % | ASTM D 882 |

| Tensile Strength (MD) | 35 - 55 | MPa | ASTM D 882 |

| Tensile Strength (TD) | 15 - 35 | MPa | ASTM D 882 |

| Surface Treatment | min. 36 | dynes/cm | ASTM D 2578a |

| Dart Drop Impact | min. 300 | g | ASTM D 1709 |

Regulatory & Compliance

- Food Contact

The BOPP Film complies with all national and international standards and requirements for food contact.

Technical Details & Test Data

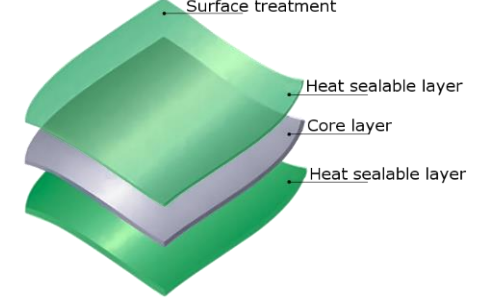

- Film Layer Representation

Packaging & Availability

- Packing

Core Diameter Outer Diameter (*) Notes Vertical

152 mm (6') max. 550 mm

max. 700 mm – two or more rows

min. 700 mm – one row76 m (3') Horizontal

152 mm (6') max. 770 mm

76 m (3') (*) In case of no other requirements.

- Tolerances

Weight Tolerance, depending on the order volume Width Tolerance Length Tolerance max. 800 - 1200 ±2 mm ±5 % 900 - 11000 min. 9500 - 10500

Storage & Handling

- Guarantee Period

Ability for printing/ lamination is guaranteed for the period of 3 months from the manufacturing date indicated on the label attached to every roll. Other parameters listed above are guaranteed for the period of 6 months from the manufacturing date.

- Storage and Transportation Terms & Conditions

- Palletizing of goods is done according to customer’s requirements

- The storage of all goods is in dry, covered and clean warehouses

- The transportation of the goods is carried out in dry, covered and clean means of transport

- The recommended temperature of storage/transportation is 10-30°C. If the temperature is not within the recommended limits, the following issues may occur:

- Decrease of dyne level

- Higher haze of the film

- Poor adhesion of the film surface that on a later stage could be an issue for laminating and printing

- Extremely low COF that can trouble further processing

- Excessive humidity can be a reason for film blocking

- Adherence to the above mentioned storage conditions ensures that the film is suitable to be used up to 6 months after production