Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 101-02-0

- EC No.

- 202-908-4

- Technologies

- Product Families

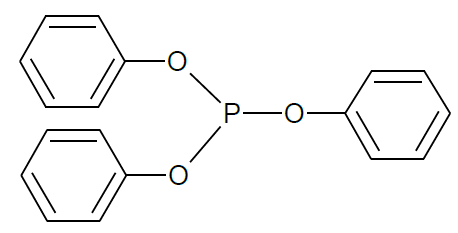

- Chemical Structure

Features & Benefits

- Key Attributes

TPP offers excellent color improvement and heat stability for polyurethane, rubber and resins. In addition, TPP is able to adjust viscosity in polyesters and act as a catalyst adjuvant in polyolefins.

Applications & Uses

- Compatible Polymers & Resins

- Product Applications

Usage of TPP include in several polymer applications which include in coatings, adhesives, epoxies, polyesters, polycarbonates, PVC etc.

Properties

- Color

- Physical Form

- Appearance

- Clear liquid

- Soluble in

- Aprotic organic solvents

- Insoluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Color (Pt/Co) | max. 50 | APHA | — |

| Specific gravity (at 25°C/15.5°C) | 1.180 - 1.186 | — | — |

| Acid Value | max. 0.2 | mg KOH/g | — |

| Refractive Index (at 25°C) | 1.587 - 1.590 | — | — |

| Phosphorus Content | 10 | % | — |

| Flash Point | 146 | °C | Pensky-Martens Closed Cup |

| Viscosity (at 38°C) | 10.2 | cps | — |

| Density (at 25°C) | 1.18 | g/mL | — |

| Vapor Pressure (at 20°C) | 5 | mm Hg | — |

Packaging & Availability

- Packaging Information

Available in 200 kg drums and 1000 kg IBC.

Storage & Handling

- Shelf Life

- 1 year

- Product Handling

In accordance with good industrial practice, handle with care and avoid unnecessary

personal contact. Use only with adequate ventilation.- Product Storage

This product may be stored in a sealed container for at least 1 year. Containers should be kept tightly closed when not in use and stored in a cool, dry place. Open drums/containers should be used as soon as possible to avoid hydrolysis especially in hot and humid environment.