Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Fast dry for improved throughput

- Outstanding chemical resistance

- Outstanding abrasion resistance

- Outstanding impact resistance

- Excellent color retention

- Solid colors only

Applications & Uses

- Applications

- Application Area

- Application Method

- Recommended Uses

Polyglass Edge is intended for industrial applications; either new build or maintenance. Polyglass Edge is suitable for application on all Endura primers.

Industries:

- Oilfield & Energy Services

- Well Service Vehicles

- Drilling

- Tanks

- Pipeline

- Cranes and Construction Equipment

- Waste and Recycling Industry

- Garbage Trucks

- Trailers and Rolling Stock

- Mix Ratio

3 parts by volume of component A and 1 part by volume of component B. The recommended temperature when mixed is 68-77°F (20-25°C).

- Surface Preparation

G90 Low VOC Topcoat can be applied over all Endura primer sealers and primer surfacers without sanding during their topcoat window. The topcoat window varies with each primer. If the primer topcoat window has been surpassed, the primer should be sanded with 240 – 280 grit sandpaper to achieve inter coat adhesion. All sanding dust must be blown off prior to application of the topcoat.

- Application Method

Polyglass Edge can be applied using most spray painting systems.

Note: Ensure that any solvent absorbent primer surfacers are properly sealed with a primer sealer prior to application of the topcoat.

Solid Colors: Apply two single wet coats allowing up to 30 minutes flash time between coats. It is recommended that a thinner first coat be applied at 1.5 – 2.0 mils wet, followed by a second wet coat of 2.0 - 3.5 mils wet. Allow up to 30 minutes between coats.

- Spray Gun Setup

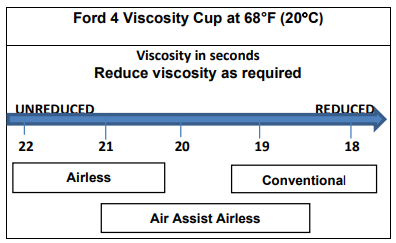

Feed Type Fluid Tip Application Pressures (Heel of Gun) Fluid Delivery Siphon Feed 1.6 - 1.8 mm 40 - 50 psi Gravity Feed 1.6 - 1.8 mm 30 - 40 psi Pressure Feed 1.0 - 1.8 mm 50 - 60 psi 10 - 14 oz/min Air Assist Airless 9 - 17 Thou 1000 - 1800 psi Airless 11 - 13 Thou 1700 - 3000 psi - Spray Viscosity

Note: Spraying viscosity and thinning will depend on ambient conditions, spray equipment used, and the desired surface finish. If required, recommended spraying viscosity is achieved by reducing with one of the desired Endura topcoat thinner/ reducer.

FTH0086 – EX-2C Thinner / Reducer

FTH0090 – Slo EX-2C Thinner /Reducer

FTH0014 – Medium Topcoat Reducer

- Film Build

Polyglass Edge has a recommended film build thickness of:

WFT (Unreduced) 3.5 - 6.0 mils 89 - 152 microns

DFT 1.5 - 2.5 mils 38 - 63 microns

Poor hiding colors film build may be higher.

Theoretical coverage at 1.0 mil (25 microns) Average DFT: 657 ft² per gallon at 100% transfer efficiency.

- Dry Times

20°C 30°C 40°C Dust Free 30 Minutes 20 Minutes 10 Minutes Full Cure 7 Days 5 - 6 Days 3 - 4 Days Note: Dry Times are subject to ambient conditions (temperature and humidity) and good airflow and film build of the topcoat. For best results surface temperature must be 86°F (30°C) or less before topcoating. Maximum re-coat window without sanding is 16 hrs at 68°F (20°C). After 16 hours G90 Low VOC Topcoat must be sanded to achieve inter-coat adhesion. Mechanical sanding with 220 – 320 grit is recommended before topcoating

Important Note: Ensure that no more than three coats of paint are applied in a 12-hour shift. This includes primer, mid-coat, topcoats, and clear coat. If more than 3 coats have been applied wait 10-12 hours to allow for proper solvent evaporation. The use of Super Catalyst II with Endura topcoats will accelerate drying times.

- Top Coating Infomation

This Product can be top coated with the entire range of Endura topcoat products.

- Clean Up

Clean all equipment immediately after use with Endura High Strength Gun Wash, or Endura EX-2C thinner.

Properties

- Finish (60°C)

- High Gloss (90+GU)

- Typical Properties

- Specifications

| Value | Units | Test Method / Conditions | |

| Volume Solids Mixed (1:1) | 37 - 45 | % | - |

| VOC Mixed (Unreduced) | 484.0 | g/l | EPA Method 24 |

| Value | Units | Test Method / Conditions | |

| Solvent Resistance (50 MEK Rubs) | No Failure | - | ASTM D4752 |

| Impact Resistance (100 in. lbs, Direct and Reverse) | No Failure | - | ASTM D2794 |

| Flexibility (1/8 in. Mandrel Bend) | No Failure | - | ASTM D2794 |

| Service Temperature | -40 to 182 | °C | - |

| Hardness | 2H | - | ASTM D3363 |

| Abrasion Resistance (1000 Cycles - CS 17, Loss) | 30 - 40 | mg | ASTM D4060 |

Regulatory & Compliance

- Certifications & Compliance

Safety & Health

- Environmental Conditions

For optimum coating performance product, substrate and ambient temperature should be between 68°F-77°F (20°C-25°C). To prevent condensation during application the surface temperature must be 5°F (3°C) or more above the dew point at all times.

Packaging & Availability

- Ordering Information (Sizing)

Available in Gallons and 5 Gal Pails Other custom sizes may be available.

1 Mixed Gallon (3.78 L) Comp A CLREXXXXX033 1 Quarts (2.84 L) Comp B FUB0300-020 1 Quart (946 ml) 4 Mixed Gallons (15.1 L) Comp A CLREXXXXX053 3 Gallons (11.34 L) Comp B FUB0300-030 1 1 Gallons (3.78 L)

Storage & Handling

- Pot Life (25°C, 50% RH)

- 1 - 3 Hours

- Shelf Life

- 3 Years (Component A, 25°C), 2 Years (Component B, 25°C)