Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Product Characteristic

EverGlide® is a unique technology based on ultra-high molecular weight silicone. It can be added to plastic at low levels providing excellent lubricity, wear and abrasion resistance in the most demanding applications.

Lubricating with EverGlide®

EverGlide® is a super lubricant which does not migrate, has thermal higher than PTFE and can be used effectively at loadings as low as 2%.- Benefits of EverGlide®

- Significantly increases in lubricity

- Low addition levels

- Minimal effect on mechanicals

- Better wear properties

- Cost effective

- Easy to handle pellets

- High thermal stability

- Approved for food contact

- No migration

- Processing aid

- Paintable

- Available in most polymers

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Siloxane Concentration | 50 | % | — |

| MFR | 35 | g/10min | — |

| MFI Conditions | 230 (2.16) | °C (kg) | — |

| Compatibility | PP | — | — |

| Process Aid / Mold Release | .2 - 2 | % | — |

| Surface Modification / Lubricity | 16 - 10% | % | — |

Technical Details & Test Data

- Improves Abrasion Resistance

EverGlide® reduces the tendency for plastic to scratch and mar easily which significantly improves the overall abrasion resistance of the plastic. Our proprietary silicone technology allows for easier movement across the surface of the polymer while introducing rubbery segments onto the surface that inhibit micro abrasions before they travel across the surface and become visible scratches.

Improves Wear Resistance While Maintaining Mechanical Properties

Improved Wear Resistance Product Total Wear Factor (in³ min/ft lb hr)x10^-8 Delrin® 500 (homopolymer) 32827 EverGlide® 1820 (homopolymer) 108 Fulton® 404 (copolymer) 192 EverGlide® 1818 (copolymer) 79 Not only does the use of EverGlide® offer unrivaled wear performance, because it’s used at a much lower level resulting in better physical properties and a more cost effective formula. In a head to head study performed by an independent third party, Delrin™500P (an acetal homo-polymer made by DuPont) and Fulton 404 ( with 20% PTFE lubrication made by Sabic IP) was compared to same polymer lubricated with EverGlide®. The polymer lubricated with EverGlide® demonstrated a 30,000% improvement in wear properties over classic unfilled Delrin materials. The Fulton with EverGlide® technology demonstrated a 243% improvement in wear properties compared to the Fulton™ classically lubricated with PTFE.

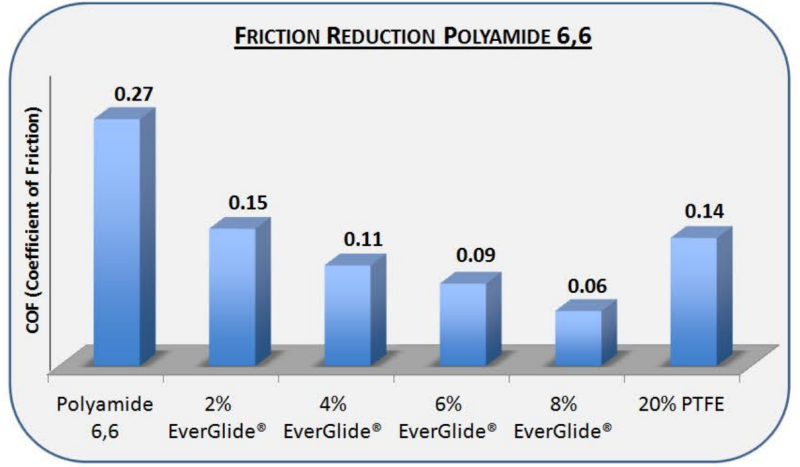

Lower Coefficient of Friction (COF)

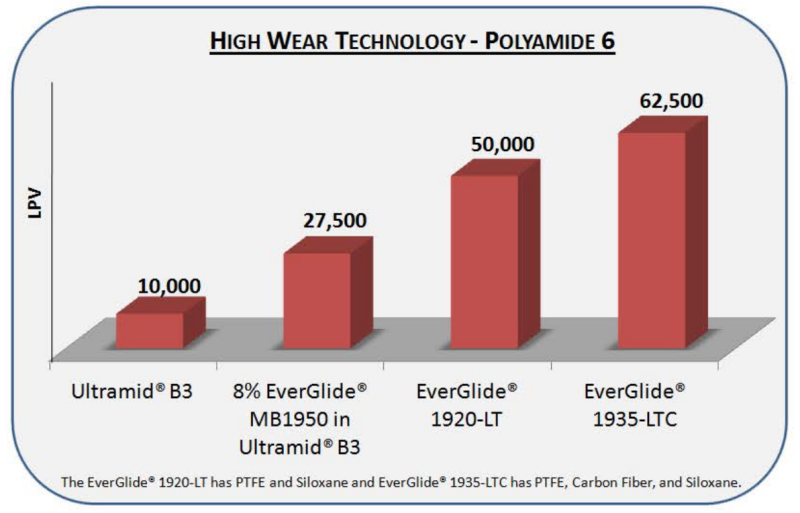

Improved Wear Performance in Polyamide 6

Using EverGlide® as a synergist in common PA6 wear formulations demonstrates an outstanding boost in performance.

Limiting-Pressure Velocity (LPV)