Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

Features & Benefits

- Ready-to-Use Product Features

- Features

- Single component, no mixing

- Ease of spread

- Easy clean-up

- VOC compliant / low VOC’s

- Anti - microbial formula

- 3-in-1 Formula

- Excellent sound abatement

- High moisture reduction

- Superior adhesion

Applications & Uses

- Markets

- Compatible Substrates & Surfaces

- Direction for Use

Follow industry standards, as well as hardwood flooring manufacturer’s recommendations for acclimation, design, layout and application of wood flooring material. If jobsite conditions are outside of flooring manufacturer’s recommendations, take necessary corrective actions.

- Surface Preparation

- Surfaces must be clean, dry and fat, free of voids, projections, loose materials, oil, grease, sealers and all other surface contaminants.

- Completely remove any adhesive residue or surface contamination by diamond grinding, shot blasting or scarifying.

- Wood should test less than 12% moisture using a wood moisture meter. To ensure proper adhesion to concrete, surface texture must be similar to light broom finished; concrete should not be smooth or reflective.

- Areas requiring patching or leveling must be done using a Portland cement-based material. Maximum acceptable floor variation is 3/16” in 10 feet.

- Applications

- Engineered hardwood flooring

- Finished & Unfinished Solid Wood

- Bamboo

- Acrylic impregnated hardwood flooring

- Curing

Humidity affects cure to a greater degree than temperature; the higher the humidity, the faster the cure. Under normal conditions, light foot traffic is acceptable after 6 to 8 hours; normal traffic after 12-16 hours.

Technical Details & Test Data

- Trowel Selector Guide/ Coverage Chart

Trowel size is suggested to maximize coverage of adhesive. Periodically check coverage of adhesive during installation : >80% coverage is required for all engineered wood flooring; >95% coverage is required for all solid wood flooring products. Please note: It is the installer’s responsibility to apply the proper amount of adhesive for the job condition.

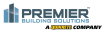

3/16"x 5/32" V Notch

<1/2"Engineered Hardwood Flooring

Coverage: 50 sq.ft/Gallon

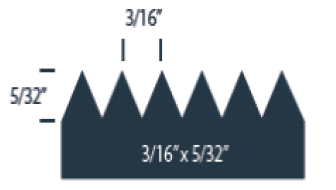

1/8"x 1/8" x 1/8" Square Notch

Finger Blodc Parquet

Coverag : 80 sq.ft/Gallon

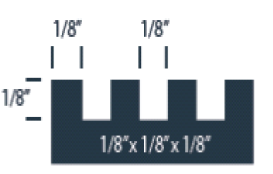

1/4"x 1/4"'x 1/8" Square Notch

1/2"Engineered Hardwood Rlooring

1/2"Solid Wood Flooring and 3/4" Parquet

Coverage : 40 sq.ft/Gallon

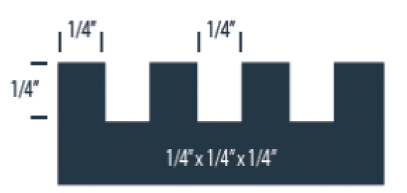

1/4'x 1/4"'x1/4" Square Notch

>1/2" Solid Wood Flooring or Plywood

Coverage : 35 sq.ft/Gallon

Packaging & Availability

- Packaging

- 1 Gallon pail : 60 pails/pallet

- 3.5 Gallon pail : 48 pails/pallet

- 4 Gallon pail : 48 pails/pallet

- 5 Gallon pail : 36 pails/pallet

- 52 Gallon drum

Storage & Handling

- Shelf Life

- 6 Months

- Storage

Material must be properly stored in a low humidity (<50% RH) environment at room temperature (71 - 75°F) in its unopened container.

- Clean - Up

As you work, immediately clean any adhesive from prefinished flooring with mineral spirits (be careful not to harm finish).

- Limitation

- Do not use on wet, dusty, contaminated, glassy smooth or friable substrates

- Do not use over substrates/slabs treated with sealers or curing compounds

- Do not use in areas subject to hydrostatic head.