Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Product Highlights

PP with PreniphorTM EPFR-100A can pass the tests of UL 94 V-0 (0.75mm), 70℃×168 hours water-immersion (UL746C), GWIT 750℃ and GWFI 960℃. Moreover, it is free from the restrictions of RoHS Directive 2002/95/EC approved by the EU and the Council. The products with PreniphorTM EPFR-100A are characterized by low density, low smoke generation and less mold corrosion. PE with PreniphorTM EPFR-100A, to some degree, may lead to the phenomenon of water-sliding surface during the process of extrusion. However, PP with PreniphorTM EPFR-100A will not come into being of this situation. Compared with PreniphorTM EPFR-100D, PreniphorTM EPFR-100A has anti-dripping agent.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Recommended Dosage

Polymer PP PP PP EPFR-100A Dosage % 32 30 24 Flame Retardancy UL 94 V-0 (0.75mm) V-0 (1.5mm) V-0 (3.0mm)

Properties

- Flame Rating

- Appearance

- White Powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.8 | g/cm3 | — |

| Average Particle Size | 10 ~ 15 | μm | — |

| Nitrogen Content | Approx. 22 | % (w/w) | — |

| Phosphorus Content | Approx. 24 | %(w/w) | — |

| Decomposition Temperature | min. 250 | °C | — |

| Water Content | max. 0.5 | %(w/w) | — |

| Water Solubility | max. 0.5 | % (w/w) | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

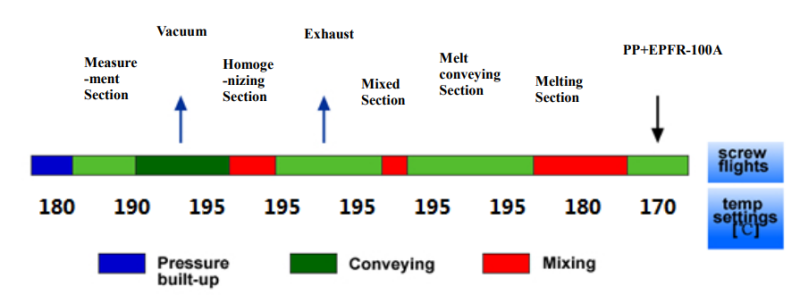

- Extrusion Process (Twin Screw Extruder)

Notes

- Because decomposition temperature of PreniphorTM EPFR-100A in nitrogen is 250 ℃, the processing temperature of twin screw extruder can be adjusted in accordance with the actual need. Under the condition of making PreniphorTM EPFR-100A dispersed and mixed homogeneous, the processing temperature should not be too high so that it can avoid decomposition of the flame retardant resulting in slight foaming. The sieve should be removed during the process of extrusion, or it’s easy to get foamed. Maintain vacuum of the twin screw extruder during the processing is also needed.

- Choose resin with suitable melt index in accordance with particular situation so that it is convenient for the processing of twin screw extrusion, injection molding and so on.

- If the dosage of carbon black is higher than 0.5%, the flame retardant performance will be weakened. Adding inorganic substances (glass fiber, calcium carbonate, talc, barium sulfate and so on) will affect the flame retardant performance. Adding additives containing Br, Cl (etc.) will lead to ineffectiveness of flame retardant.

Packaging & Availability

- Packaging

25kg/package.

Storage & Handling

- Storage

Transported as the common chemicals. Keep in dry, cool place and avoid direct sunlight