Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Product Characteristics

Flame retarded by Preniphor™ EPFR-110DM, polyolefin and glass fiber reinforced polyolefin can reach UL 94 V-0 (1.5mm) and pass Glow Wire test of GWIT 750°C and GWFI 960°C. And it is free from the restrictions of RoHS Directive 2002/95/EC approved by the EU and the Council. The products with Preniphor™ EPFR-110DMare characterized by low density, low smoke generation, good thermal stability, high flame retarded efficiency, and excellent dispersion. Polyolefin with Preniphor™ EPFR-110DM will not lead to the phenomenon of water-sliding surface during the process of extrusion due to its ammonium polyphosphate free system

- Advantages

- Preniphor™ EPFR-110DM is halogen-free and eco-friendly with low smoke and toxicity.

- Preniphor™ EPFR-110DM will not lead to the phenomenon of water-sliding surface for its high processing temperature in extruding progress.

- Preniphor™ EPFR-110DM has an excellently mechanical performance with a low dosage and low density. And product with Preniphor™ EPFR-110DM has stable color.

- Preniphor™ EPFR-110DM owns an excellent flame retarding performance in solid phase with a high content of phosphor, which is recommended for polyolefin.

- Preniphor™ EPFR-110DM would lead to little dust, which contributes to creating a healthy working environmental for workers

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Recommanded Dosage

Polymer PP LDPE HDPE PP+GF(15%) PP+GF(20%) PP+GF(25%) Preniphor™ EPFR-110DM Dosage % 22~24 28~30 30~32 23~25 25~28 28~30 Flame Retardancy UL 94 V-0 (1.5mm)

Properties

- Flame Rating

- Appearance

- White Powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Nitrogen Content | Approx. 22 | %(w/w) | — |

| Phosphorous Content | Approx. 20 | %(w/w) | — |

| Water Content | max. 0.5 | %(w/w) | — |

| Bulk Density | Approx. 790 | g/L | — |

| Whiteness | min. 93 | % | — |

| Average Particle Size | Approx. 10 | μm | — |

| TGA (10°C/min, in N2) Weight Loss 1% | min. 280 | °C | — |

| TGA (10°C/min, in N2) Weight Loss 5% | min. 290 | °C | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

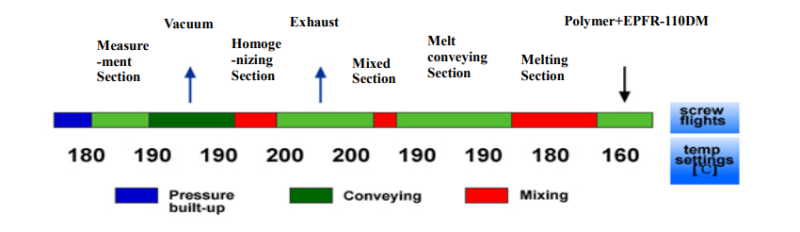

- Extrusion Process (Twin Screw Extruder)

- The decomposition temperature of Preniphor™ EPFR-110DM in nitrogen is 280℃, thus the processing temperature of twin screw extruder can be adjusted higher accordingly. Sieves can be put on the head of machine. Maintaining vacuum of the twin screw extruder during the processing is also needed.

- The substances which affect flame retardant performance: phthalocyanine green that contains Cl-1 toner will make the flame retardant loss effect. If the dosage of carbon black is higher than 0.5%, the flame retardancy will be weakened.

- Acid-resistant processing machines have to be used for extrusion and molding since Preniphor™ EPFR-110DM is acidic in nature.

Packaging & Availability

- Packaging

25kg/package.

Storage & Handling

- Storage

Transported as the common chemicals. Keep in dry, cool place and avoid direct sunlight.