Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Product Characteristics

TPE with Preniphor™ EPFR-400A can pass the tests of UL 1581 VW-1. Moreover, it is free from the restrictions of RoHS Directive 2002/95/EC approved by the EU and the Council. The products with Preniphor™ EPFR-400A are characterized by smooth appearance, strong precipitation resistance, excellent water and migration resistance, good electrical properties, no toxicity and low smoke generation. Preniphor™ EPFR-400A is more suitable for the injection products and wires with normal surface requirements. No anti-dripping agent. About 2‰ of anti-dripping agent (such as TF 1645 from 3M corporation) can be added in accordance with the actual demand of the customers.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Recommended Dosage

Polymer Polyester-based Thermoplastic Polyurethane

Thermoplastic elastomer TPE

EPFR-400A Dosage % 16 20 6%-8%400A+10-20%MCA

Flame Retarding performance UL 94 UL 94 V-0 (1.5mm) or UL 1581 VW-1 UL 94 V-0 (0.75mm) or UL 1581 VW-1 UL 1581 VW-1

Properties

- Flame Rating

- Appearance

- White Powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | Approx. 1.25 | g/cm3 | — |

| Bulk Density | Approx. 400 | g/L | — |

| Nitrogen Content | max. 13 | %(w/w) | — |

| Phosphorous Content | min. 30 | %(w/w) | — |

| Decomposition Temp. | min. 260 | ℃ | — |

| Average Particle Size | Approx. 6 | μm | — |

| Water Content | max. 0.3 | %(w/w) | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

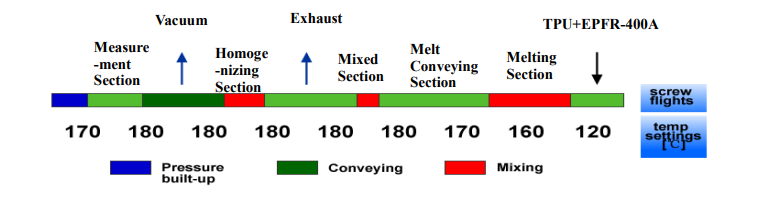

- Extrusion Process (Twin Screw Extruder)

Notes

Notes

The raw material needs pre-drying. Make the content of moisture as low as possible. Moderate the processing condition so as to avoid the degradation of thermoplastic polyurethane.

Packaging & Availability

- Packaging

25kg/package.

Storage & Handling

- Storage

Transported as the common chemicals. Keep in dry, cool place and avoid direct sunlight.