Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

- Extra slow cure speed hardener provides provides 7 to 8 hours working time at 77°F (25°C). A typical laminate will be gelled in 12 to 14 hours.

- Optimized for hand wet out and machine impregnation in contact molding, vacuum bagging and Light RTM applications with a minimum cure temperature of 72°F (22°C).

- Room temperature cure properties suitable for many composite components and structures.

- Tg as high as 198°F (92°C) with proper post cure providing excellent temperature stability and great part cosmetics.

- Cost effective, high performance epoxy formulation for synthetic composite manufacturing.

Applications & Uses

- Applications

- Compatible Reinforcements

- Composites Processing Methods

- Mix Ratio

Method Resin:Hardener Resin:Hardener Weight 3.50:1 100:28.6 Weight Range 3.64:1–3.16:1 100:27.48–100:31.60

Volume 3.00:1 100:33.3 Volume Range 3.07:1–2.67:1 100:32.60–100:37.49

Properties

- Mechanical Properties

- Typical Properties

- Thermal Properties

- Handling Properties

- Conditions

1 - 1 Hz, 3°C per minute

3 - Store PRO-SET® Epoxy resins and hardeners at room temperature in sealed containers until shortly before use. As with many high-performance epoxy resins, repeated exposure to low temperatures during storage may cause the resin to crystallize. If this occurs, warm the resin to 125° F and stir to dissolve crystals. Hardeners may form carbamation when exposed to CO2 and moisture in the atmosphere for extended periods of time. Prevent carbamation by protecting hardeners from exposure until immediately prior to processing.

| Value | Units | Test Method / Conditions | |

| Compression Yield (22°C, 4 wk) | 16000.0 | psi | ASTM D695 |

| Compression Yield (25°C, 2 wk) | 16200.0 | psi | ASTM D695 |

| Compression Yield (RT Gelation, 49°C [8 hours]) | 14200.0 | psi | ASTM D695 |

| Compression Yield (RT Gelation, 60°C [8 hours]) | 14200.0 | psi | ASTM D695 |

| Compression Yield (RT Gelation, 82°C [8 hours]) | 14200.0 | psi | ASTM D695 |

| Flexural Modulus (22°C, 4 wk) | 520000.0 | psi | ASTM D790 |

| Flexural Modulus (25°C, 2 wk) | 526000.0 | psi | ASTM D790 |

| Flexural Modulus (RT Gelation, 49°C [8 hours]) | 506000.0 | psi | ASTM D790 |

| Flexural Modulus (RT Gelation, 60°C [8 hours]) | 489000.0 | psi | ASTM D790 |

| Flexural Modulus (RT Gelation, 82°C [8 hours]) | 460000.0 | psi | ASTM D790 |

| Flexural Strength (22°C, 4 wk) | 13700.0 | psi | ASTM D790 |

| Flexural Strength (25°C, 2 wk) | 11500.0 | psi | ASTM D790 |

| Flexural Strength (RT Gelation, 49°C [8 hours]) | 17500.0 | psi | ASTM D790 |

| Flexural Strength (RT Gelation, 60°C [8 hours]) | 17500.0 | psi | ASTM D790 |

| Flexural Strength (RT Gelation, 82°C [8 hours]) | 17500.0 | psi | ASTM D790 |

| Hardness (22°C, 4 wk) | 92.0 | Shore D | ASTM D2240 |

| Hardness (25°C, 2 wk) | 91.0 | Shore D | ASTM D2240 |

| Hardness (RT Gelation, 49°C [8 hours]) | 93.0 | Shore D | ASTM D2240 |

| Hardness (RT Gelation, 60°C [8 hours]) | 93.0 | Shore D | ASTM D2240 |

| Hardness (RT Gelation, 82°C [8 hours]) | 93.0 | Shore D | ASTM D2240 |

| Tensile Elongation (22°C, 4 wk) | 2.0 | % | ASTM D638 |

| Tensile Elongation (25°C, 2 wk) | 1.6 | % | ASTM D638 |

| Tensile Elongation (RT Gelation, 49°C [8 hours]) | 3.5 | % | ASTM D638 |

| Tensile Elongation (RT Gelation, 60°C [8 hours]) | 3.0 | % | ASTM D638 |

| Tensile Elongation (RT Gelation, 82°C [8 hours]) | 6.2 | % | ASTM D638 |

| Tensile Modulus (22°C, 4 wk) | 534000.0 | psi | ASTM D638 |

| Tensile Modulus (25°C, 2 wk) | 551000.0 | psi | ASTM D638 |

| Tensile Modulus (RT Gelation, 49°C [8 hours]) | 500000.0 | psi | ASTM D638 |

| Tensile Modulus (RT Gelation, 60°C [8 hours]) | 493000.0 | psi | ASTM D638 |

| Tensile Modulus (RT Gelation, 82°C [8 hours]) | 448000.0 | psi | ASTM D638 |

| Tensile Strength (22°C, 4 wk) | 9000.0 | psi | ASTM D638 |

| Tensile Strength (25°C, 2 wk) | 7700.0 | psi | ASTM D638 |

| Tensile Strength (RT Gelation, 49°C [8 hours]) | 8990.0 | psi | ASTM D638 |

| Tensile Strength (RT Gelation, 60°C [8 hours]) | 8990.0 | psi | ASTM D638 |

| Tensile Strength (RT Gelation, 82°C [8 hours]) | 8990.0 | psi | ASTM D638 |

| Value | Units | Test Method / Conditions | |

| Cured (22°C) | 9.6 | lb | — |

| Hardener (22°C) | 7.95 | lb | — |

| Resin (22°C) | 9.58 | lb | — |

| Value | Units | Test Method / Conditions | |

| Heat Deflection Temperature (22°C, 4 wk) | 127.0 | °F | ASTM D648 |

| Heat Deflection Temperature (25°C, 2 wk) | 128.0 | °F | ASTM D648 |

| Heat Deflection Temperature (RT Gelation, 49°C [8 hours]) | 149.0 | °F | ASTM D648 |

| Heat Deflection Temperature (RT Gelation, 60°C [8 hours]) | 158.0 | °F | ASTM D648 |

| Heat Deflection Temperature (RT Gelation, 82°C [8 hours]) | 170.0 | °F | ASTM D648 |

| Tg DMA Onset Storage Modulus (22°C, 4 wk) | 143.0 | °F | ASTM E16401 |

| Tg DMA Onset Storage Modulus (25°C, 2 wk) | 146.0 | °F | ASTM E16401 |

| Tg DMA Onset Storage Modulus (RT Gelation, 49°C [8 hours]) | 162.0 | °F | ASTM E16401 |

| Tg DMA Onset Storage Modulus (RT Gelation, 60°C [8 hours]) | 175.0 | °F | ASTM E16401 |

| Tg DMA Onset Storage Modulus (RT Gelation, 82°C [8 hours]) | 198.0 | °F | ASTM E16401 |

| Tg DMA Peak Tan Delta (22°C, 4 wk) | 158.0 | °F | ASTM E16401 |

| Tg DMA Peak Tan Delta (25°C, 2 wk) | 160.0 | °F | ASTM E16401 |

| Tg DMA Peak Tan Delta (RT Gelation, 49°C [8 hours]) | 196.0 | °F | ASTM E16401 |

| Tg DMA Peak Tan Delta (RT Gelation, 60°C [8 hours]) | 196.0 | °F | ASTM E16401 |

| Tg DMA Peak Tan Delta (RT Gelation, 82°C [8 hours]) | 220.0 | °F | ASTM E16401 |

| Tg DSC Onset– 1st Heat (22°C, 4 wk) | 134.0 | °F | ASTM E1356 |

| Tg DSC Onset– 1st Heat (25°C, 2 wk) | 137.0 | °F | ASTM E1356 |

| Tg DSC Onset– 1st Heat (RT Gelation, 49°C [8 hours]) | 152.0 | °F | ASTM E1356 |

| Tg DSC Onset– 1st Heat (RT Gelation, 60°C [8 hours]) | 159.0 | °F | ASTM E1356 |

| Tg DSC Onset– 1st Heat (RT Gelation, 82°C [8 hours]) | 177.0 | °F | ASTM E1356 |

| Tg DSC Ultimate (RT Gelation, 49°C [8 hours]) | 184.0 | °F | ASTM E1356 |

| Value | Units | Test Method / Conditions | |

| Pot Life (22°C, 150g) | 192 - 236 | Minutes | ASTM D2471 |

| Pot Life (22°C, 500g) | 136 - 168 | Minutes | ASTM D2471 |

| Pot Life (25°C, 150g) | 130 - 159 | Minutes | ASTM D2471 |

| Pot Life (25°C, 500g) | 89 - 109 | Minutes | ASTM D2471 |

| Pot Life (29°C, 150g) | 76 - 94 | Minutes | ASTM D2471 |

| Pot Life (29°C, 500g) | 64 - 80 | Minutes | ASTM D2471 |

| Viscosity (Hardener, 22°C) | 33.0 | cP | ASTM D2196 |

| Viscosity (Resin, 22°C) | 1731.0 | cP | ASTM D2196 |

| Viscosity Mixed (22°C) | 655.0 | cP | ASTM D2196 |

| Viscosity Mixed (25°C) | 514.0 | cP | ASTM D2196 |

| Viscosity Mixed (29°C) | 375.0 | cP | ASTM D2196 |

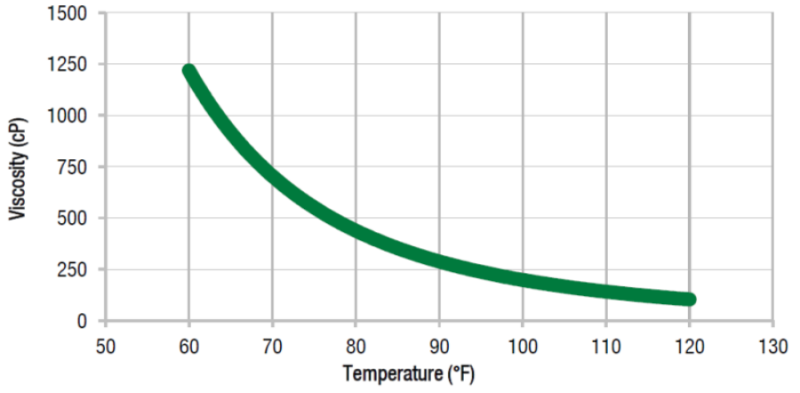

Technical Details & Test Data

- Viscosity vs Temperature