Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Ingredient Origin

- Ingredients

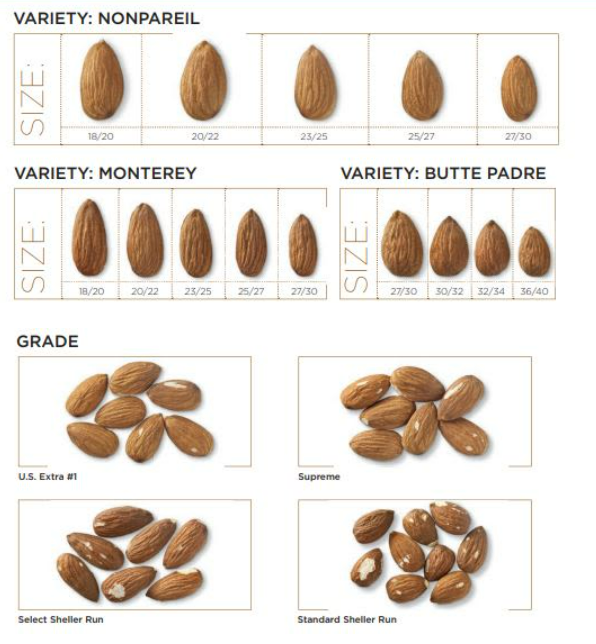

- Almonds

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

- Compliance

Quality Assurance

- All products undergo a test, hold and release program ensuring compliance with specifications.

- Upgraded, custom-designed Statistical Process Control system.

- Contracted with accredited ISO-17025 third-party laboratory with on-site testing facilities. Capability to adhere to U.S., E.U. and other international testing protocols.

- Pasteurization process approved by the Almond Board of California.

- 100% allergen separation between almonds and pistachios.

- All flavored products are tested weekly against sensory benchmarks.

Quality Control

- All facilities are staffed with full-time and dedicated Quality Control personnel.

- Each manufacturing process is supervised by Quality Control personnel.

Audit Qualifications

- Members of the American Council for Food Safety & Quality.

- USDA inspectors on-site.

- All facilities FSSC 22000 Certified

Technical Details & Test Data

- Natural Almonds

Safety & Health

- Food Safety

- Robust and industry-leading environmental swabbing program for food and non-food contact points.

- Intensive pest monitoring and prevention program. Dedicated pest control staff supported by a third-party contractor.

- All employees undergo extensive food safety training with mandatory compliance initiatives.

- Hand sanitizers, foot baths and other measures incorporated into all ready-to-eat areas.

- Master sanitization schedule including foaming, dry cleaning techniques and dry ice blasters throughout all facilities, supported by dedicated plant-specific teams.

- Outreach program invites university professors, industry food safety experts, technical consultants and microbiologists to review our food safety procedures.

Packaging & Availability

- Shipping Information

PRODUCT PACKING UNIT NET WEIGHT STANDARD CONTAINER QUANTITY LBS KGS Container Quantity Net Weight LBS Net Weight KGS In-shell Bags 50 22.68 40' Container 860 bags on slip sheets

or wood pallets43,000 19,505