Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Benefits

• Non-chlorinated solvent (NC).

• Fast High tack.

• Portable and convenient.

• Excellent green strength and high heat resistance.

Applications & Uses

- Markets

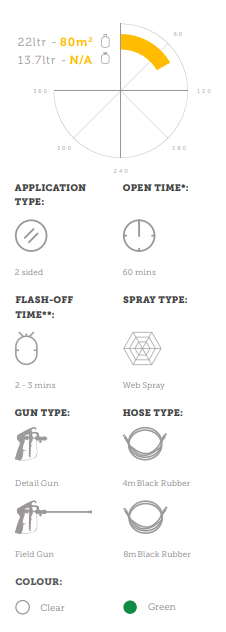

- Application Method

- Direction For Use

- This product is designed to be applied to two surfaces to be bonded together. For best results, the temperature of the adhesive and the surfaces being bonded should be between 60 ˚F - 80 ˚F (16 ˚C - 27 ˚C).

- Use with adequate ventilation. When possible we recommend shaking the canister well before using.

- Attach and secure hose tightly onto the spray gun with required tip. Attach the other end of the hose onto the canister. Make sure the hose-valve connections are securely tight. Open the valve on the canister slowly and fully, check for leaks during this process. Unlock the trigger on the spray gun to start spraying.

- Prior to use, check compatibility by spraying a small test patch of the adhesive on the substrate. This product may degrade some substrates.

- Make sure that surfaces are clean, dry and free from dirt, dust, oil, loose paint, wax or grease, etc.

- Spray about 10-20 cm (4” – 8”) away at a 90 degree angle to the surface, with 50% overlaps applying a uniform, even coat of adhesive to obtain 80% to 100%

- coverage of the surface. If necessary, spray another coat of adhesive in areas that appear to need more adhesive.

- Spray both surfaces to be bonded, one surface vertically and the other surface horizontally.

- Allow 2 - 3 minutes for the adhesive to tack off until no adhesive transfers to the knuckle when touched.

- Adhere surfaces and press together with adequate pressure. A roller is recommended to apply a uniform pressure to achieve maximum strength. Allow 24 hours for the adhesive to fully cure.

- If the spray tip clogs, unscrew the spray tip from the gun and clean with solvent such as lacquer thinner or acetone. Do not use a pin on the spray tip.

Properties

- Appearance

- Clear or Green

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Temperature Resistance | -30 - 90 | °C | — |

| Solvent System | Non-chlorinated | — | — |

| Coverage | 80.0 | m2 | — |

| Solids | 28 - 33 | % | — |

| VOC Content | 574.0 | grams per litre | — |

Technical Details & Test Data

- Square Metre Coverage

Packaging & Availability

- Packaging Type

Storage & Handling

- Shelf Life

- 18 Months

- Storage

- 2021-05-25

- Canister Storage/Change Over

- Turn valve on canister into the off position, spray out remaining adhesive left in the hose, disconnect the spray hose and gun from the canister.

- Reconnect the spray hose to a canister of cleaning solvent (sold separately) and spray out until liquid is clear which indicates that the hose and gun is clean.

- If you choose to leave the hose and spray gun on the canister, leave the valve on the canister open.

- Do not disconnect the hose/gun from the canister.

- Close and lock the spray gun.

- Handling and Storage

- Do not store at temperatures over 50°C.

- Avoid exposure to direct sunlight.

- Do not store directly on concrete floor.

- For optimum performance, store at 18°C during use, but must always be above 10°C.

- When connected, keep valve open and hose pressurized at all times.

- Do not close valve until ready to connect to new cylinder.

- Release pressure in hose before disconnection.

- Always test product to determine suitability for your particular application prior to use in production.