Knowde Enhanced TDS

Identification & Functionality

- Technologies

Features & Benefits

- Ready-to-Use Product Features

- Product Info

B-45 handles harsh environments easily and is particularly effective against moisture, salt water, acids, alkalies, oils, gasoline and detergents. B-45 has high thermal stability, with a continuous operational rating of -50°F to +350°F. B-45 offers good corrosion resistance. The flexible properties of B-45 permit assembly of materials with dissimilar thermal expansion and will survive thermal cycling. Likewise mechanical vibration, shock and impact are easily absorbed by B-45 and it protects surfaces, bonded assemblies and encapsulated sensitive electronics is superior in performance to urethane adhesives, sealants and coatings. B-45 is useful as a direct replacement for urethane elastomers with the superior benefits that it requires no primer for adhesion and offers high chemical resistance. B-45 is also available as a paste or caulking compound and electrically or thermally conductive compounds. Apply B-45 by roller or brush. B-45 is very easy to use with low HAZMAT impact with no plasticizers that bloom to the surface and no solvents causing VOC problems. The product is also available in the thixotropic version B-45TH, providing a thick coating on vertical surfaces which will not sag, and yet is easily poured from a can.

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Curing Guide

A wide range of curing regimes may be employed: ambient set in 4 hours, tack free in 12 hours, and 97% cure in 24 hours. Post curing at 150°F, after 2 hours at ambient to allow bubble escape, will cure 98% in 4 hours; or 3 hours at 200°F for 100% cure. Mix part A with part B, 2:1 ratio by volume or weight. Degassing is optional. Pot life is typically 30 - 40 minutes, at ambient temperature. Surface prep by abrading or grit blasting substrates with #100 AlOx followed by degrease and/or alcohol wipe for optimum adhesion.

- High Chemical Resistance

Superior chemical resistance for moisture, gasoline, oil, acids and bases in continuous full submersion. High thermal stability in a rugged flexible system. Excellent for exterior and interior applications

- Easy Use

Two part, primerless, flexible epoxy, ambient and thermal cure. Low HAZMAT impact. Available in handheld and pneumatic gun actuated cartridges, quarts, gallons and drums

- Harsh Environments

- "

Marine, Industrial, Downhole oil, Underwater, Mining, Industrial,, Automotive.

" - Coats & Seals Dissimilar Materials

A protective coating, conformal coat, electronic - electrical encapsulant and potting epoxy that bonds to dissimilar materials such as plastics including UHMW, HDPE, PP, PET, PEEK, PPS, PBT, Acetal, ETFE, PVC, PVCF, PVDF, ABS, ECTFE, polyamide, polyimide, rubber and urethane compounds as well as metal, glass, composites, cement, wood and cellulose.

Technical Details & Test Data

- B-4X Series Epoxy Product Comparison Guide

Product Elongation Tensile Strength Durometer Key property B-45 100% to 130% 1300 PSI Flexible, urethane rubber-like properties. 80 A-Shore Excellent balance of strength, chemical

resistance, good adhesion to very wide

range of substrates including Delrin

and HDPE (lightly abraded), good

electrical properties. Suitable for

adhesive, potting and coating

applications- Test Data

Lapshear test: ASTM D3163; all values mean; all failures adhesive/cohesive at plastic-adhesive interface.

Adhesive

Substrate

#1

Substrate

#2

Dure

Temp

°F

Peak

Stress

PSI

Sample

Range Hi/Lo

Peak Stress

PSI

Strain

Peak

Load

%

Energy

Peak

Load

In-Lb

Break

Stress

PSI

Elongation

at Break

%

Yield

Stress

PSI

Elongation

at Yield

%

Tangent

Modulus

PSI

B-45

HDPE

HDPE

150

295

299/290

1.65

2.96

290

1.7

295

1.7

22882

B-45

UHMW

UHMW

150

312

—-

3.16

5.81

307

3.3

308

2.7

14184

B-45

UHMW

UHMW

150

279

325/256

2.22

3.69

279

2.4

274

2.3

14478

B-45

UHMW

UHMW

Ambient*

283

308/246

2.20

3.69

282

2.2

279

2.1

15760

B-45

UHMW

Steel

150

424

484/364

1.74

4.69

424

1.6

424

1.6

33556

B-45

UHMW

Steel

Ambient*

361

401/326

1.68

3.7

361

1.7

361

1.7

27291

B-45

PPS

SS

150

812

—-

1.05

4.61

813

1.0

813

1.0

82478

B-45

PPS

SS

Ambient**

492

—-

0.77

2.25

490

0.8

492

0.8

77347

B-45

ABS

PVC

150

677

677/677

2.68

10.39

676

2.8

677

2.8

27247

B-45

ACETAL

ACETAL

150

339

362/323

1.50

3.20

339

1.5

333

1.5

24759

*Ambient cure 31 days **Ambient cure 7 days

Peel tests

Adhesive

Substrate #1

Substrate #2

Failure mode

B-45

PBT

PET

cohesive/adhesive failure of PET film

B-45

PBT

Polyurethane foam

cohesive failure of PU foam

B-45

PEEK

PET

cohesive/adhesive failure of PET film

B-45

PEEK

Polyurethane foam

cohesive failure of PU foam

B-45

G10 fiberglass

PET

cohesive/adhesive failure of PET film

B-45

G10 fiberglass

Polyurethane foam

cohesive failure of PU foam

B-45

Neoprene

Steel

cohesive failure of rubber

B-45

Neoprene

Neoprene

cohesive failure of rubber

B-45

EPDM

Steel

cohesive failure of rubber

B-45

Butyl

Aluminum

cohesive failure of rubber after 500°F, 8 minute exposure

Note that the above test results were obtained from testing B-45TH; however B-45 should show the same results.

- Typical Properties

Gasoline - No effect to slight increase in durometer, ambient

Acids - Little or no effect, > pH 4, <85%, ambient

Bases - Little or no effect, < 13 pH, < 85%, ambient

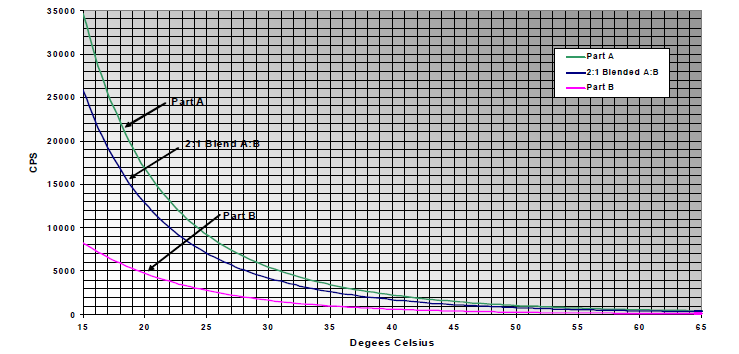

- Viscosity Bondit B-45

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage

The usable shelf life of unopened containers of BONDiTTM B-45 resin is one year, and should be stored in cool, dry place. When not in use, containers should be kept tightly closed.BONDiTTM B-45 is available in side-by-side handheld and pneumatic actuated gun cartridges, quarts, gallons, pails and drums. Custom packaging, such as premixed and degassed frozen cartridges, is also available