Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Features

- Typical RM-XXXX Resin Properties

- Straightforward 350°F Cure.

- Designed for demanding aerospace structural applications.

- Developed for optimized tack and handle ability.

- Delivers an excellent balance of properties for service up to 300oF.

- Available in woven, unidirectional and slit-tape product forms using all fibers including carbon, quartz and glass.

- Nano-enhancements for tailored laminate properties and multi-functional performance available.

Applications & Uses

- Markets

- Composites Processing Methods

- Recommended cure cycle

All temperatures and times are based upon the lagging thermocouple unless otherwise specified.

Step 1. Vacuum hold for 60 minutes at room temperature

Step 2. Heat 1 – 10°F/ minute to 350 ± 10°F apply 30 ± 5 psig pressure until temperature reaches 225 ± 5°F

Step 3. Apply 85 ± 5 psig autoclave pressure and vent to atmosphere.

Step 4 Hold temperature at 350 ± 10°F for 120 +15/ -0 minutes.

Step 5. Cool at 1 – 10°F/ min, when temperature is below 150°F release pressure.

Properties

- Physical Form

Technical Details & Test Data

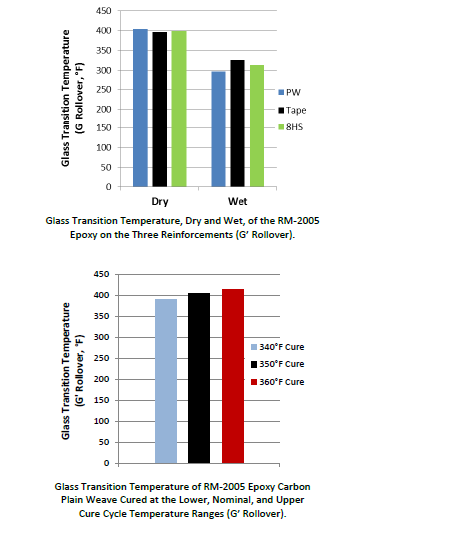

- Glass Transition Temperature Data

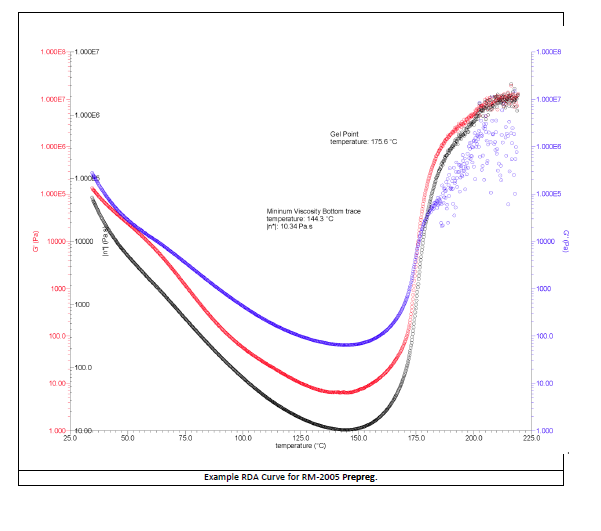

- Viscosity Profile

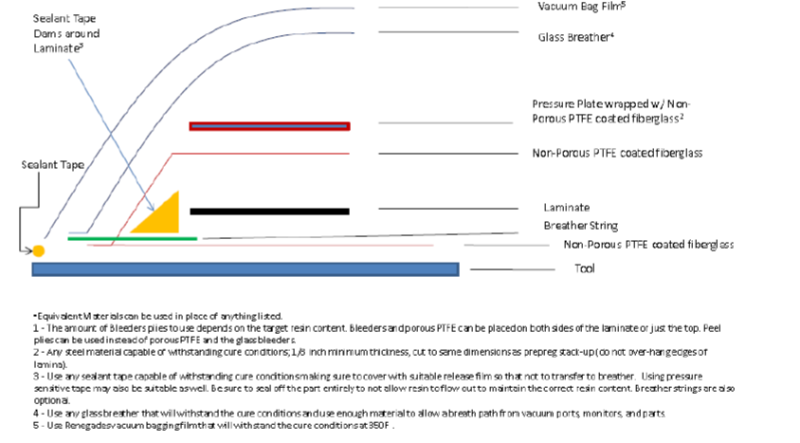

- Bagging Scheme