Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Features

- Typical RM-XXXX Resin Properties

- Straightforward 250°F Cure.

- Designed for ease of processing.

- Developed for optimized tack and handling.

- Delivers an excellent balance of properties for service up to 200oF dry or 160°F wet conditions.

- Available in woven, unidirectional and tape product forms using all fibers including carbon, quartz and glass.

Applications & Uses

- Markets

- Composites Processing Methods

- Recommended cure cycle

- 85 psi, Vent vacuum at 30 psi

- Heat 4°F/min to 250°F, hold 90 minutes

- Cool 4°F/min to 150°F, then release pressure

Properties

- Physical Form

- Resin Properties

| Value | Units | Test Method / Conditions | |

| Cured Resin Density | 1.21 | g/cc | - |

| Resin Flex Strength | 25 | ksi | - |

| Resin Flex Modulus | 526 | Msi | - |

| Resin Flex Strain to Failure | 5 | % | - |

Technical Details & Test Data

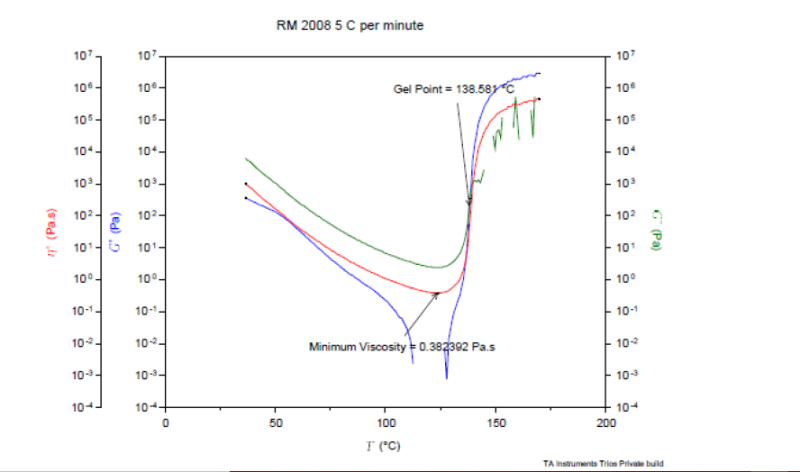

- Viscosity Profile