Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Features

- Excellent Dielectric Properties.

- Lower cost than Cyanate Esters.

- Low Minimum Buys; No Set-Up Charges.

- Straightforward 300°F (150°C) Autoclave Cure Cycle.

- Vacuum Bag/Oven (VBO) Cure Option.

- Delivers an Excellent Balance of Properties for Service up to 180°F (83°C) Wet.

- Available on a Wariety of Fabrics including Quartz, Glass and Carbon.

Applications & Uses

- Applications

- Composites End Use

- Composites Processing Methods

- Recommended cure cycle

Autoclave Cure Cycle

- Ramp at 2-5°F/min to 300°F with 50 to 85 psi pressure.

- Vent to atmosphere at 30 psi pressure.

- Cure for 4 hours.

- Cool at 2-5oF/min.

Vacuum Bag/Oven Cure Cycle

Apply full vacuum to start; hold for 30 minutes before start of heating cycle.

Ramp at 3oF/ minute to 250oF hold for 30 minutes

Ramp at 3oF/min to 300oF hold for 4 hours

Cool at 5oF/ minute to 150oF under vacuum.

Properties

- Physical Form

- Resin Properties

| Value | Units | Test Method / Conditions | |

| Cured Resin Density | 1.26 | g/cc | — |

| Resin Flex Strength | 25 | ksi | — |

| Resin Flex Modulus | 526 | Msi | — |

| Resin Flex Strain to Failure | 5 | % | — |

Technical Details & Test Data

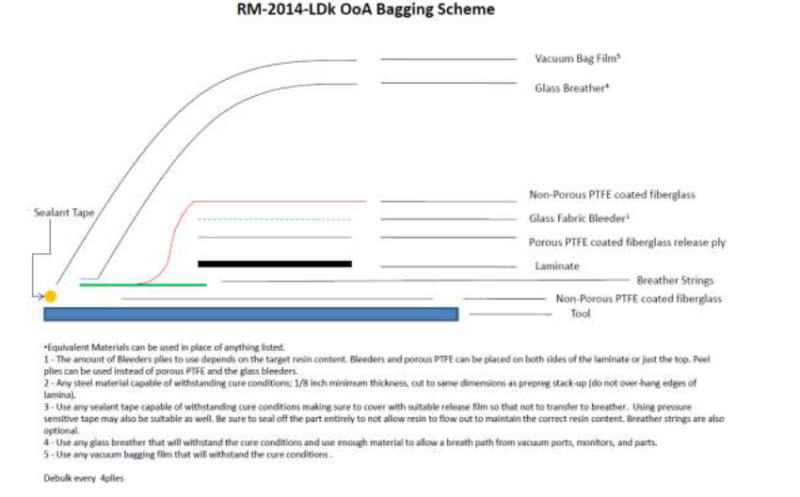

- Bagging Scheme