Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Composites Processing Methods

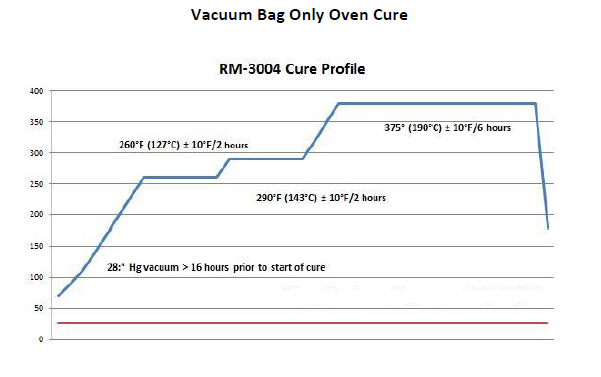

- Recommended cure cycle

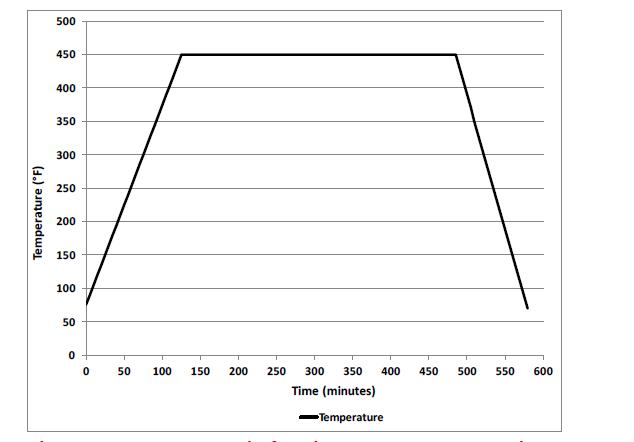

- Recommended Post Cure Cycle

In an Air Circulating Oven

Step 1: Heat to 475°F±10°F (246°C±5.56°C) at 3°F(1.67°C)/min

Note: Lower temperature post cures may be more appropriate for

your application depending on your Tg requirements.

Step 2: Hold 6 hours

Step 3: Cool to 70°F (21°C) at 4°F(2.22°C)/min

Properties

- Physical Form

Technical Details & Test Data

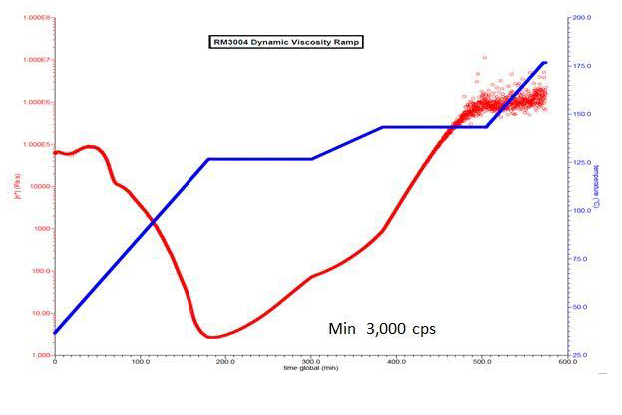

- Viscosity Profile

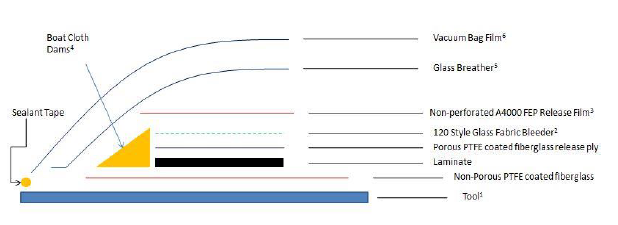

- Bagging Scheme

*Equivalent Materials can be used in place of any of the bagging materials shown above.

*Equivalent Materials can be used in place of any of the bagging materials shown above.- Any steel material capable of withstanding the cure conditions may be used; 1/8” minimum thickness.

- The number of bleeder plies to be used depends upon the target resin content. Bleeder plies can be placed on both sides of the laminate or just on top. If placing bleeders on the bottom, add a piece of porous PTFE coated fiberglass release ply against the laminate.

- Fold up layers of boat cloth to the thickness of the panel to create a dam around the part. This will create a path for gasses to escape and provide sufficient edge breather.

- Use any glass breather that will withstand the cure conditions and use enough material to allow a breather path from the vacuum ports, monitors and parts.

- Use any vacuum bagging film that will withstand the cure conditions.