Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Features

- 350°F Cure

- Designed for demanding electrical, radome and antennae applications.

- Developed for optimized tack and handle ability.

- Delivers superior performance with service up to 350oF with post cure.

- Available in woven and unidirectional product forms using all fibers including carbon, quartz and glass.

- Nano-enhancements for tailored laminate properties and multi-functional performance available.

Applications & Uses

- Applications

- Composites End Use

Properties

- Physical Form

- Resin Properties

| Value | Units | Test Method / Conditions | |

| Cured Resin Density | 1.18 | g/cc | — |

| Resin Flex Strength | 20 | ksi | — |

| Resin Flex Modulus | 530 | ksi | — |

| Resin Flex Strain to Failure | 4.5 | % | — |

Technical Details & Test Data

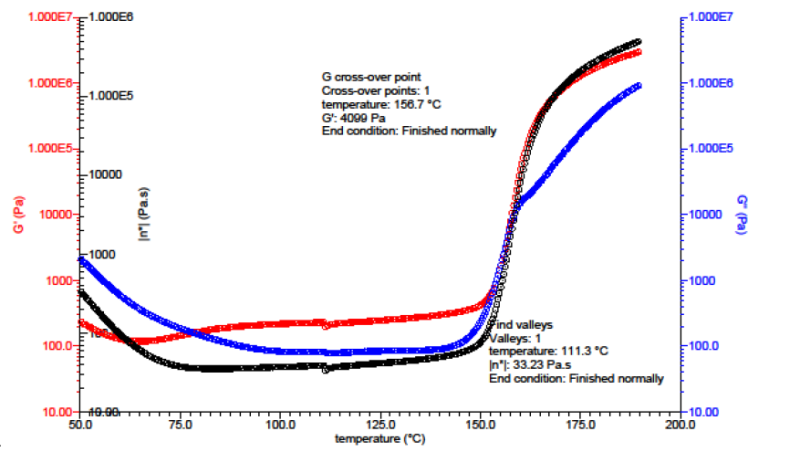

- Viscosity Profile and Recommended cure cycle

Recommended Autoclave Cure Cycle: At Full Vacuum and 85-psi, Ramp at 1-5°F

Per Minute to 350°F and Hold for 90-minutes.