Knowde Enhanced TDS

Identification & Functionality

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Features

- This prepreg is intended for use as a Light-Weight, Flame-Resistant Barrier Layer for Composite Aircraft Structures.

- It is applied to a pre-cured polyimide composite part, in a secondary co-cure with RM-1005 Polyimide Adhesive Film.

- The resulting Hybrid Composite Structure is then oven post-cured (in air).

Applications & Uses

- Markets

- Composites Processing Methods

Properties

- Physical Form

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Thermal Conductivity | 0.2 | W/mK | Calculated from Thermal Diffusivity, Heat Capacity and Density |

| Thermal Diffusivity | 0.0016 | cm2/s | ASTM E1461 Linseis LFA 1000 Laser Flash Apparatus using 1” discs |

| HeatCapacity at 70°F | 0.82 | J/g/°C | DSC |

| Coefficient of Thermal Expansion (x,y) | 7 | ppm/°C | TMA |

| Coefficient of Thermal Expansion (z) | 36 | ppm/°C | TMA |

Technical Details & Test Data

- Product Forms

- Woven Glass Fabric Prepreg, ~ 30-mil or ~60-mil thick options

- Style 4581 Quartz Fabric, ~ 9-mil thick

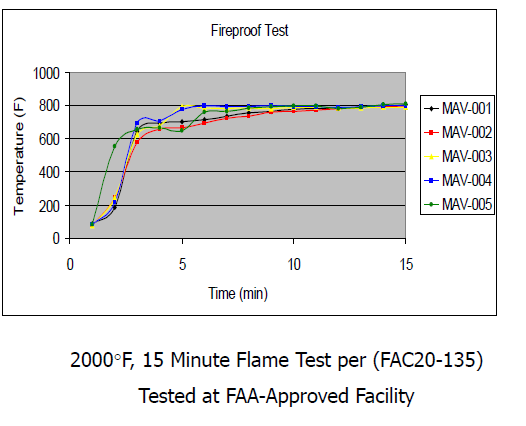

- Testing shows 1200oF delta from the Hot-side (poly-ceramic/glass) to the Back-side (polyimide), during FAA Flame Testing.

- Good tack, drape and out-time at ambient conditions.

- No Tg is observedusing DMA/TMA, tested up to 800°F.

- Polyceramic Fire Testing

- Instructions

- Assure pre-cured polyimide part surface is clean and ready for bonding.

- Apply one ply RM-1005 Polyimide Adhesive Film

- Apply RM-6001 prepreg

- Choose bagging materials suitable for 400°F cure temperature.

- Construct a vacuum bag for a No / Low bleed process.

- Use a non-porous breather material cut oversized or to size and laid across the panel,

- Seal with tacky-tape and damsand test for leaks.

- Cure Cycle and Post cure

Autoclave Cure Cycle: - Note: RM-6001 prepreg loses some volatile content at approximately 180°F, and begins to cure at approximately 250°F

- Apply 10-15” vacuum

- Heat 5°F/min to 235 ±10°F, and hold for 30-minutes

- Apply 100-psi

- Heat 5°F/min to 400±10°F, and hold for 2-hours

- Cool 10F/min

Oven Post Cure:- The hybrid structure is then oven post-cured (in air), using a slow heat-ramp rate from Room Temperature to 650°F (with RM-1100 parts) and hold at temperature for 6-8 hours.