Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- CAS No.

- 204583-39-1

- EC No.

- 440-520-9

- Technologies

- Product Families

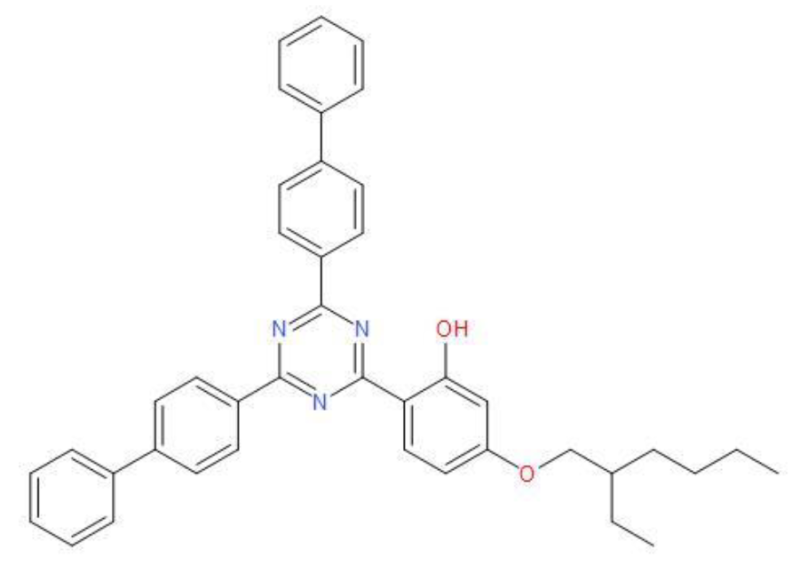

- Chemical Structure

- Molecular Formula

C41H39N3O2

Features & Benefits

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- RIASORB® UV-1600 is an ultraviolet light absorber (UVA) of the hydroxyphenyl triazine class exhibiting very low volatility, high absorption and good compatibility with a variety of polymers, co-additives and resin compositions. Compared to conventional hydroxyphenyl triazine, benzotriazole or cyanoacrylate UV absorbers, RIASORB® UV-1600 allows polycarbonates, polyesters, and acrylics to achieve a higher resistance to weathering.

- RIASORB® UV-1600 applications include polyalkene terephthalates and naphthalates, linear and branched polycarbonates, acrylics (PMMA) and their copolymers, modified polyphenylene ether compounds, various high performance plastics, PA, SAN, ASA, as well as polyolefins.

- The use of RIASORB® UV-1600 is indicated in polymer blends & alloys as well as in reinforced, filled and/or flame retarded compounds, which can be transparent, translucent and/or pigmented. Due to its very low volatility, excellent thermal stability and high extinction coefficient, RIASORB® UV-1600 is particularly suitable for processing and aging conditions where high loadings, very good compatibility, and outstanding durability are required. Such requirements are especially critical for thin layers and films in general, e.g. extruded or co-extruded articles such as plain, multi-wall and corrugated sheets, oriented and biaxially oriented thin films, co-extruded or co-injected semi-finished parts, fibers and complex moldings.

Properties

- Appearance

- Slightly yellow powder

- Typical Properties

- Solubility

| Value | Units | Test Method / Conditions | |

| Molecular Weight | 605.78 | — | — |

| Value | Units | Test Method / Conditions | |

| Acetone (at 20℃) | 0.2 | g/100g | — |

| Chloroform (at 20℃) | 55 | g/100g | — |

| Ethanol (at 20℃) | 0.9 | g/100g | — |

| Ethyl Acetate (at 20℃) | 2 | g/100g | — |

| Methyl Methacrylate (at 20℃) | 8 | g/100g | — |

| Methylene Chloride (at 20℃) | 53 | g/100g | — |

| THF (at 20℃) | 54 | g/100g | — |

Regulatory & Compliance

- Certifications & Compliance

Safety & Health

- Handling & Safety

The use of proper protective equipment is recommended. Excess exposure to the product should be avoided. Wash thoroughly after handling.

Storage & Handling

- Storage Conditions

Store the product in a cool, dry, well-ventilated area away from incompatible materials, keep tightly closed.