Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Polymer Type

- Silane terminated polyether

- CAS No.

- 1497417-11-4

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Characterestic

- High Activity , Low Modulus

High transparence

Good adhesion strength and tensile elasticity

Fast curing , non-tin catalysts used if needed, more eco-friendly

Excellent aging and yellowing resistance

Excellent water resistance , resistance to chemical corrosion

Excellent elastic recovery rate

Excellent storage stability

Solvent free , odorless , eco-friendly

Could be blended with other Risun polymers

- High Activity , Low Modulus

- properties and Features

KERILON® 201S polymer is used as base polymer in elastic sealants, elastic structure sealants, encapsulate adhesives and coatings . The curing mode of the polymer is moisture curing, It can be made into a single component or two-components system.

- Low modulus construction sealant

- Transportation industry elastic sealant

- Low viscous encapsulate adhesive

- Personal DIY sealant

- Eco-friendly decoration sealant

- Product Characterestic

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Cure Method

- Adhesive & Sealant Type

- Applications

KERILON® 201S polymer is used as base polymer in elastic sealants, elastic structure sealants, encapsulate adhesives and coatings . The curing mode of the polymer is moisture curing, It can be made into a single component or two-components system.

- Low modulus construction sealant

- Transportation industry elastic sealant

- Low viscous encapsulate adhesive

- Personal DIY sealant

- Eco-friendly decoration sealant

- Instructions

Instructions

KERILON® 201S polymer can be quickly dissolved in ordinary organic solvents (such as ethanol), but almost insoluble in water. So the raw materials in the formula system are mostly oil-soluble substances. KERILON® 201S polymer curing mechanism, silane of both ends with the help of the catalyst react with water forming hydrolysis to generate Silanol, Silanol is crosslinked with catalyst to form a siloxane bond, resulting in a network-like structure. Although the 201S polymer has a highly reactive group, it can remain stable in the air for a period of time in a catalyst-free environment. Water is a very important factor during the storage and processing.In order to stabilize the processing and storage, it must add a certain amount of chemical water removal agent, we recommend the use of vinyl trimethoxysilane. Conventional mixing process can be suitable for KERILON® 201S POLYMER. For more technical support, please consult our technical engineers.Cleaning

This product can be removed before curing by the general solvent, such as ethanol, dimethyl carbonate. After curing can only be removed by mechanical means.

Properties

- Physical Form

- Appearance

- Clear viscous liquid

- Soluble in

- Virtually Insoluble

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Cap Type | Both ends of the mixed end | — | — |

| Boiling Point | min. 250 | °C | — |

| Gravity | 1.005 | g/cm3 | — |

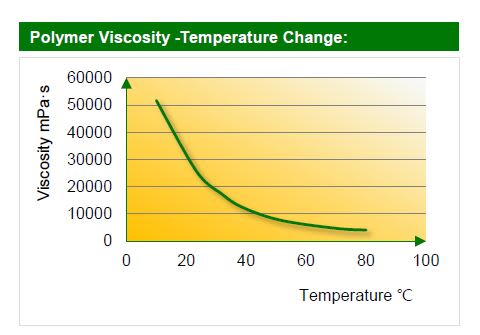

| Viscosity at 25°C | 7000 - 10000 | mPa·s | — |

| Flash Point | min. 237 | °C | — |

Packaging & Availability

- Packaging Type

- Packaging

- 50kg plastic drum lined with aluminum foil bag

- 200kg drum lined with aluminum foil bag

- 1000kg IBC

Storage & Handling

- Storage

Storage

Because this product is moisture sensitive, If unopened and stored at 4℃-30℃ dry environment, the shelf life is 12 months. Use it as soon as possible if opened, the remain products should be resealed and stored at 4℃-30℃ dry environment. But if shelf life expired, you can still use it only after your positive confirmation of production performance.- Shelf Life

Minimum 12 months at 25℃/50% RH.