Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Characteristics

Viscous, high elongation, thermoplastic, non-toxic, cushioning, lubricating.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Modifications and Additives

Specific oils for exudation, fragrances, over-the-counter (OTC) additives, triglyceride based formulations.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Durometer, Shore 00 | 22 | — | — |

| Tensile stress (at 100% Strain) | 5.2 | psi | — |

| Tensile stress (at 300% Strain) | 10.9 | psi | — |

| Ultimate Tensile Strength | 126 | psi | — |

| Tensile stress at break | 111 | psi | — |

| Elongation | 2000 | % | — |

| Compression Set (*) | max. 1 | % | — |

| Glass transition temperature, Tg | max. -50 | °C | — |

Technical Details & Test Data

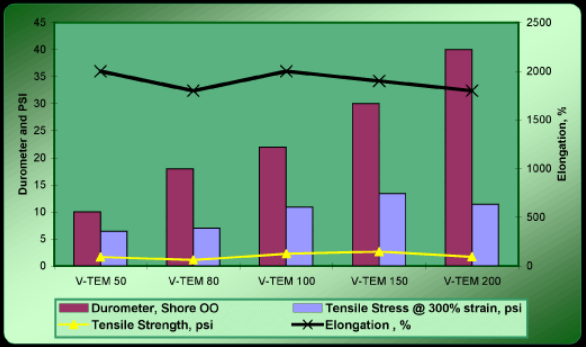

- Product Graph