Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Resins and Compounds for Water Management Applications

SABIC’S specialty resins and compounds offer the water management industry design flexibility to produce products with longer lives and higher quality. Our materials are excellent candidates to replace metal and can provide weight reduction, corrosion resistance, high strength and stiffness or inherent lubricity depending on the application’s requirements.

- Internally lubricated

- Low Wear in Aqueous Environments

- Low coefficient of Friction

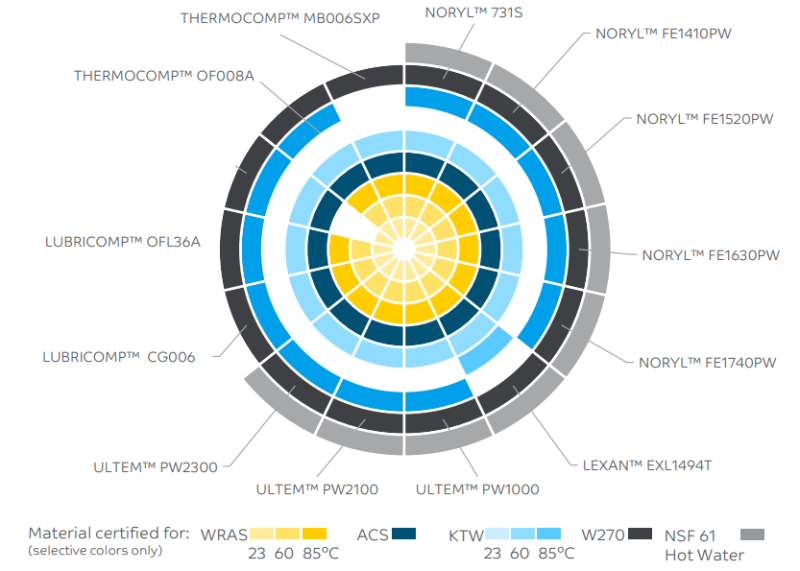

In addition to mechanical requirements, applications for the water management industry need certification for potable water compliance according to national standards. SABIC has developed a dedicated potable water certified portfolio to help our customers accelerate their application development time to market.

SABIC Offerings Certified for Water Management Applications:

For applications that do not require potable water certification, SABIC’s Specialties portfolio includes a wide range of specialized thermoplastic compounds based on different base resins and fillers.

Properties

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Impact Properties

- Injection Molding

- Note

- ᵍ Measurements made from Laboratory test Coupon. Actual shrinkage may vary outside of range due to differences in processing conditions, equipment, part geometry and tool design. It is recommended that mold shrinkage studies be performed with surrogate or legacy tooling prior to cutting tools for new molded article.

- ⁷ Injection Molding parameters are only mentioned as general guidelines. These may not apply or may need adjustment in specific situations such as low shot sizes, large part molding, thin wall molding and gas-assist molding.

- ¹¹ The information stated on Technical Datasheets should be used as indicative only for material selection purposes and not be utilized as specification or used for part or tool design.

| Value | Units | Test Method / Conditions | |

| Tensile Stress (Break, 5 mm/min) ¹¹ | 45 | MPa | ISO 527 |

| Tensile Strain (Break, 5 mm/min) ¹¹ | 1.3 | % | ISO 527 |

| Tensile Modulus (at 1 mm/min) ¹¹ | 6200 | MPa | ISO 527 |

| Flexural Stress (Break, 2 mm/min) ¹¹ | 72 | MPa | ISO 178 |

| Flexural Modulus (at 2 mm/min) ¹¹ | 5400 | MPa | ISO 178 |

| Tensile Stress (Break, Type I, 5 mm/min) ¹¹ | 6600 | MPa | ASTM D638 |

| Tensile Strain (Break, Type I, 5 mm/min) ¹¹ | 1.2 | % | ASTM D638 |

| Flexural Stress (Break, 1.3 mm/min, 50 mm span) ¹¹ | 74 | MPa | ASTM D790 |

| Flexural Modulus (at 1.3 mm/min, 50 mm span) ¹¹ | 2100 | MPa | ASTM D790 |

| Value | Units | Test Method / Conditions | |

| Mold Shrinkage (on Tensile Bar, flow) ᵍ ¹¹ | 0.1 - 0.3 | % | SABIC method |

| Wear Factor Washer ¹¹ | 799 | 10^-10 in^5-min/ft-lb-hr | ASTM D3702 Modified: Instr. |

| Dynamic COF ¹¹ | 0.3 | — | ASTM D3702 Modified: Instr. |

| Static COF ¹¹ | 0.55 | — | ASTM D3702 Modified: Instr. |

| Density ¹¹ | 1.22 | g/cm³ | ISO 1183 |

| Value | Units | Test Method / Conditions | |

| Vicat Softening Temperature (Rate B/50) ¹¹ | 99 | °C | ISO 306 |

| Vicat Softening Temperature (Rate B/120) ¹¹ | 101 | °C | ISO 306 |

| Heat Deflection Temperature/Af (at 1.8 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 89 | °C | ISO 75/Af |

| Heat Deflection Temperature/Bf (at 0.45 Mpa, Flatw 80*10*4, sp=64mm) ¹¹ | 97 | °C | ISO 75/Bf |

| Value | Units | Test Method / Conditions | |

| Izod Impact (Unnotched, 80*10*4, at 23°C) ¹¹ | 10 | kJ/m² | ISO 180/1U |

| Izod Impact (Notched, 80*10*4, at 23°C) ¹¹ | 2 | kJ/m² | ISO 180/1A |

| Charpy Impact (Unnotched, at 23°C) ¹¹ | 6.5 | kJ/m² | ISO 179/2C |

| Charpy Impact (Notched, at 23°C) ¹¹ | 1.2 | kJ/m² | ISO 179/2C |

| Charpy Impact (at 23°C, Unnotch Edgew 80*10*3 sp=62mm) ¹¹ | 6.5 | kJ/m² | ISO 179/1eU |

| Charpy Impact (at 23°C, V-notch Edgew 80*10*3 sp=62mm) ¹¹ | 1.2 | kJ/m² | ISO 179/1eA |

| Izod Impact (Unnotched, at 23°C) ¹¹ | 80 | J/m | ASTM D4812 |

| Izod Impact (Notched, at 23°C) ¹¹ | 12 | J/m | ASTM D256 |

| Value | Units | Test Method / Conditions | |

| Drying Temperature ⁷ | 80 | °C | — |

| Drying Time ⁷ | 4 | Hrs | — |

| Melt Temperature ⁷ | 250 | °C | — |

| Front - Zone 3 Temperature ⁷ | 265 - 275 | °C | — |

| Middle - Zone 2 Temperature ⁷ | 245 - 255 | °C | — |

| Rear - Zone 1 Temperature ⁷ | 220 - 230 | °C | — |

| Mold Temperature ⁷ | 40 - 65 | °C | — |

| Back Pressure ⁷ | 0.2 - 0.3 | MPa | — |

| Screw Speed ⁷ | 30 - 60 | rpm | — |

Packaging & Availability

- Regional Availability