Knowde Enhanced TDS

Identification & Functionality

- Technologies

Features & Benefits

- General Features

-

The first active edge sealant to keep moisture out of sensitive packages.

-

An easy replacement of high performance edge sealants, boosting barrier properties through a proprietary getter technology .

-

Breakthrough time > 1,500 hours on 4 mm line width at 60 °C/90% RH.

-

Compatible with any surface suitable for UV‐curing.

-

Now with increased adhesion performances.

-

Applications & Uses

- Applications

- Applications

-

Active Matrix OLED displays

-

Passive Matrix OLED displays

-

OLED lighting systems

-

Organic photovoltaic devices

-

Organic sensors

-

OFETs

-

OLETs

-

Organic lasers

-

Properties

- Color

- Physical Form

- Appearance

- Whitish Glue

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (25°C) | 110000.0 | cP | — |

| Thermal Stability (100°C, <<1% wt loss) | Stable | — | — |

| Decomposition Temperature | min. 300 | °C | — |

| Glass Transition Temperature | 110.0 | °C | — |

| Pot Life (RT, < 10 ppm H2O) | min. 5 | days | — |

| Lap Shear | min. 8.0 | MPa | — |

| CTE (100°C) | 5.4*10^-3 | 1/°C | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Processing

Bring ZeoGlue‐HV to room temperature before use. Deposition must be carried out in dry environment.

Deposition

-

Typical dispensing by syringe (needle diameter > 0.1 mm)

-

Compatible surfaces are:

-

Glass

-

Stainless Steel and other metals (one‐side only e.g. metal to glass)

-

Plastics if compatible with UV curing

-

Curing

-

UV Curing is required

-

Suggested curing conditions are:

-

irradiance of 100mW/cm2 for > 120s with λ = 365 nm.

-

thermal post curing at 80°C for 30 minutes.

-

max irradiance: < 500mW/cm2.

-

max energy density: < 12J/cm2.

-

Curing must take place in glove box (< 10 ppm H2O).

-

Weight loss during curing: < 0.2 %.

-

-

- Cleaning

Typical solvent used for cleaning is Acetone or Acetic acid diluted at 5% in water.

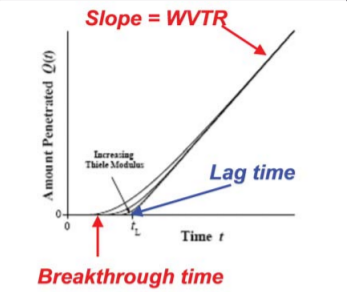

- Barrier Properties: The Concept of Breakthrough Time

Barrier Properties Value unit WVTR (23°C 65% RH (300 μm) after Saturation*) < 0.1 g/m2 day Breakthrough Time (on 4 mm Line Width at 60 °C/90% RH) >1500(**) hour (*) In glass to glass configuration, on properly cured film. During breakthrough time the WVTR is theoretically zero and lower than the limit of detection.

(**) This can be considered equivalent to 2.5 years at 25 °C 30% RH. After this transient period the glue keeps working as state‐of‐art passive barrier, as shown with the reported WVTR after saturation.

Packaging & Availability

- Ordering Information

Code Description 5X0400 ZEOGLUE‐HV/SMU10 (Musashi syringe ‐ 10cc) 5X0401 ZEOGLUE‐HV/SMU50 (Musashi syringe ‐ 50cc) 5X0402 ZEOGLUE‐HV/S1/SMU10 (with spacers) 5X0403 ZEOGLUE‐HV/SEU10 (EFD syringe ‐ 10cc) 5X0404 ZEOGLUE‐HV/SEU50 (EFD syringe ‐ 50cc) 5X0405 ZEOGLUE‐HV‐0/SEU10

Storage & Handling

- Storage

-

Shelf life of ZeoGlue‐HV is 6 months.

-

Storage conditions are temperature of +2 ‐ +5 °C and dry atmosphere.

-

ZeoGlue‐HV can be stored in a normal refrigerator provided that the original packaging is not open, or it is sealed in dry atmosphere.

-

In the event of exposure at temperature higher than 50°C, ZeoGlue must be discarded.

-

- Handling and Air Exposure

-

Barrier bag should be opened in glove box (< 10 ppm H2O).

-

Opening in air must be avoided.

-

In the event of air exposure, ZeoGlue‐HV must be discarded.

-

Before use, it must be left at room temperature for at least 2 hours; otherwise viscosity could be higher than the nominal value.

-

Uncured ZeoGlue‐HV can be maintained at room temperature for maximum 120 hours before using.

-