Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Carrier

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Ink & Toner Type

Properties

- Appearance

- Brown Yellow Pellets.

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Softening Point | 117 ± 5 | Ball and Ring /℃ | - |

| Viscosity (Gardner-Holdt /25℃) | *E ~ H | - | - |

| Sp.Gr.(25) | 0.98 | ℃ | - |

| Acid Value | max. 10 | mg KOH/g | - |

| Amine Value | max. 10 | mgKOH/g | - |

Technical Details & Test Data

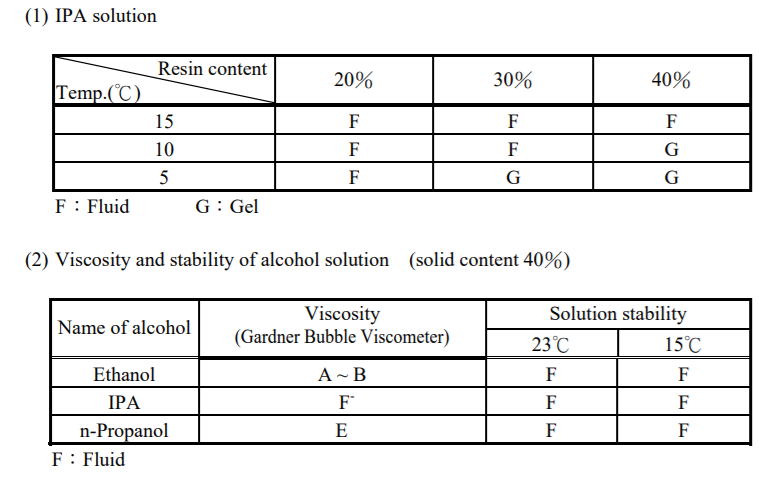

- Solution Stability

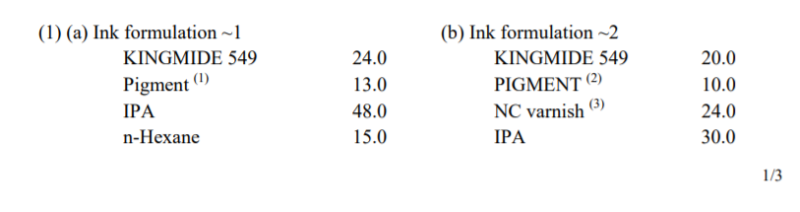

- FLEXOGRAPHIC-INK TEST

Ink viscosity (Zahn cup No.4)

- Ink formulation ~1 10.8 s

- Ink formulation ~2 22.3 s

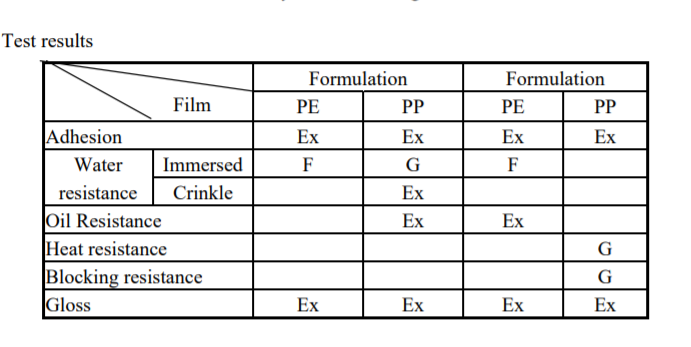

Printing test

The above test ink was printed using a test rotogravure plate onto a treated

polyethylene film and treated polypropylene film and the ink films were then subjected to

various tests as follows:- Adhesion test:Cellotape Test

- Water resistance:The printed film was immersed into tap water for 24 hours. Water

- was wiped off of the ink film and the cellotape test and crinkle test

- was made.

- Oil resistance:24 hours after printing soyabean oil was applied onto the ink film and

- after 24 hours rubbing test by using Rubo-tester. load 200g 50 strokes.

- Heat resistance:Treated polypropylene film was employed in this case. Heat sealing

- test was conducted with a seal tester, load 2 kgf/㎝ 2 and sealing time

- 0.5 s.

- Blocking resistance:Treated polypropylene film was employed in this case. Using IPI Type Blocking tester. Test condition:Temp. 50℃, Humidity 80%, load 1 kgf /㎝ 2, 24 hours.

- FLEXOGRAPHIC-INK TEST ( The ink was prepared by ball milling. )

- Test Results

Packaging & Availability

- Packaging Type