Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

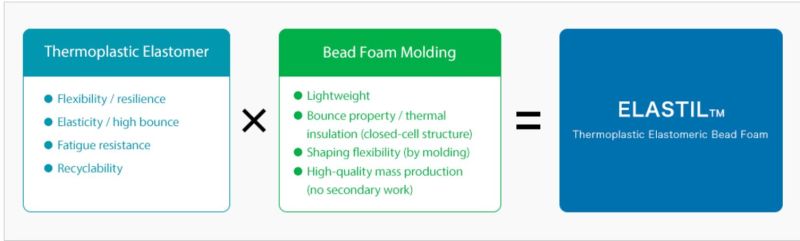

Features & Benefits

- Materials Features

- Features

・Energy-Returning Responsiveness : The rubber-like material is bouncier than EPS and traditional soft foams, offering responsive energy return.

・Flexible : The material has a similar flexibility to traditional soft foams, despite being expanded polystyrene.

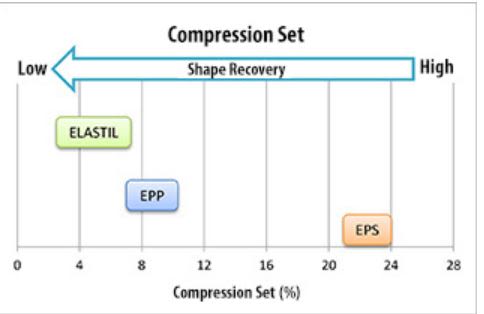

・Shape Restorability : With the compression permanent set of 5% or less, the material exhibit good shape restorability, making it less susceptible to deformity.

・Can be molded into any shape : Pre-expanded resin beads are filled into molds to produce foams of the most complex shapes.- Product Highlight

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Applications

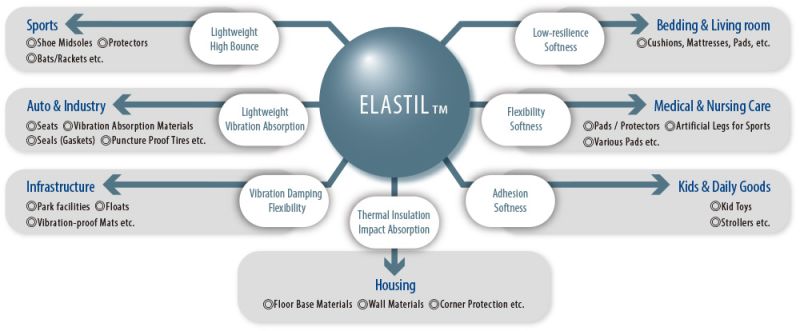

Taking advantage of ELASTIL’s properties such as lightweight, flexibility, high bounce and elasticity, it can be used the following fields and applications:

Properties

- Elastil Has Excellent Properties

Lightweight

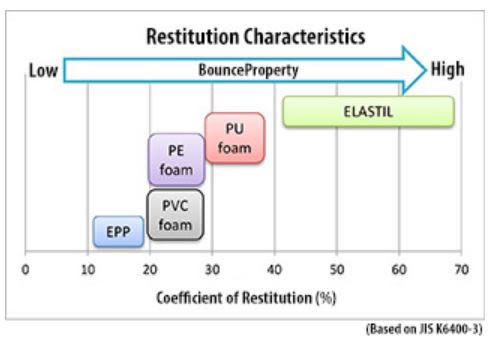

Density of ELASTIL is 0.10~0.15 [g/cm³] which is very lightweight.Bounce property / Elasticity

ELASTIL has extremely outstanding properties of bounce and elasticity compared with the other foams, PU foam/PVC foam (open cells), and EPP (closed cells). Such properties like a spring and lightweight property can be used for a wide range of applications.

Flexibility / Softness

ELASTIL is very flexible and soft, and has high resilience property which conventional bead foams could not achieve. The compression set of ELASTIL flexible grade is about 3-6 %, thus the strain after compression does not remain easily compared with EPS and EPP.

Shapability / Mass Productivity

ELASTIL is molded with steam heat after filling small particles (pre-expanded beads) into a mold/tooling. Different from foam boards, it has high degree of design freedom and does not need secondary work, such as cutting, sealing and trimming, even in 3D shapes.Non-absorbent / Thermal Insulation

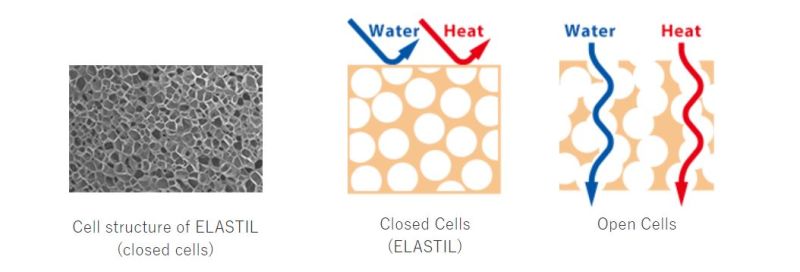

ELASTIL foams have the closed cell structure therefore it has less absorption and better thermal insulation than open-celled soft foams.