Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Applications

- Compatible Reinforcements

- Composites End Use

- Composites Processing Methods

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Mixing ratio by weight | 100/24 | g/g | — |

| Mixing ratio by volume | 100/30 | ml/ml | — |

| Bio-based Carbon Content | 20 - 23 | % | — |

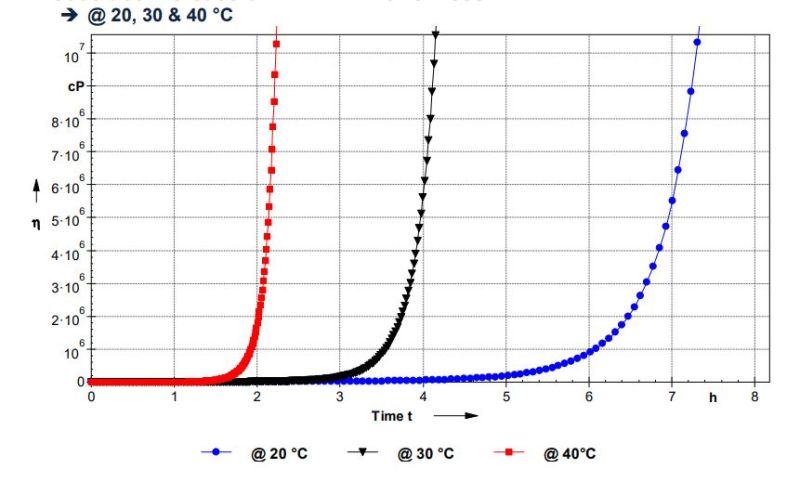

| Initial Viscosity at 20°C | 2000 | mPa.s | — |

| Initial Viscosity at 30°C | 750 | mPa.s | — |

| Initial Viscosity at 40°C | 400 | mPa.s | — |

| Gel Time at 20°C | 7 | hrs | — |

| Gel Time at 30°C | 3.45 | hrs | — |

| Gel Time at 40°C | 2 | hrs | — |

| Tg Onset Maximum | 150 | °C | — |

Technical Details & Test Data

- Viscosities increase on 1 mm film thickness