Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

- Chemical Cure System

Oxime

Features & Benefits

- Ready-to-Use Product Features

- Product Features

Fast RT cure

Excellent unprimed adhesion to plastic, metal and glass

Thixotropic paste

Non-corrosive neutral cure

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Cure Method

- Typical Applications

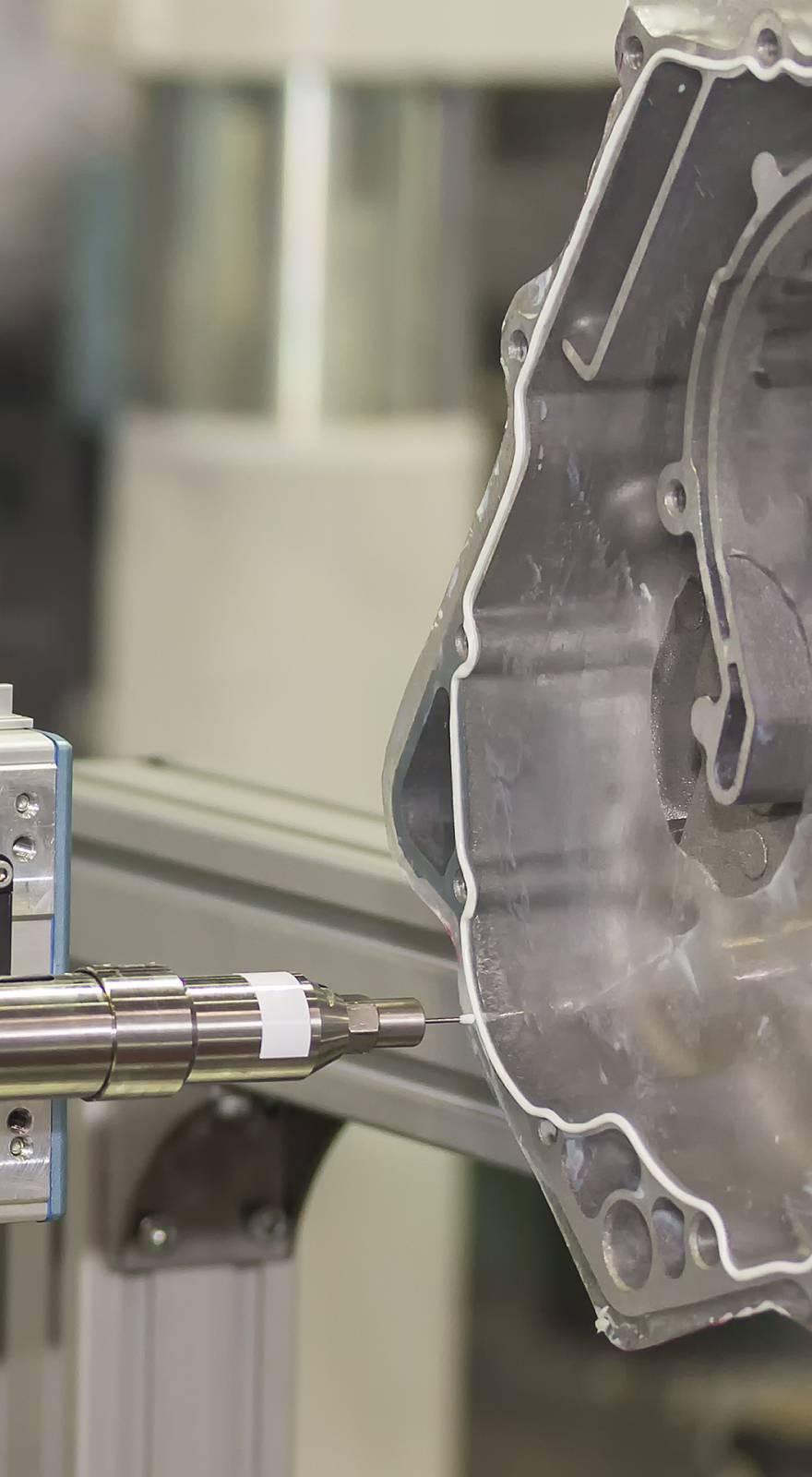

- Industrial bonding

- Assembly line adhesive

- Component assembly

- Limitations

Do not use product on head gaskets, solvent or fuel immersion applications. Allow to fully cure before putting assembly into service. Ensure enough product remains between flanges to be effective in an assembly.

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity | 500000 | cps | — |

| Specific Gravity | 1.12 | — | — |

| Consistency | Thixotropic Paste | — | — |

| Working Time at RT | 8.0 | Minutes | — |

| Tack Free Time at RT | 15.0 | Minutes | — |

| Application Rate (90 psi) | 175.0 | g/min | — |

| Cure Time (72 Hours at RT) | 5.0 | Minutes | — |

| Durometer | 50.0 | Shore A | — |

| Tensile Strength | 900.0 | psi | — |

| Elongation | 800.0 | % | — |

| Peel Strength | 100.0 | psi | — |

| Tear Strength | 100.0 | pli | — |

| Dielectric Strength | 500.0 | KV/mm | — |

| Dielectric Constant | 2.8 | — | — |

| Dissipation Factor | 0.001 | — | — |

| Volume Resistivity | 4.4 x 1014 | — | — |

Technical Details & Test Data

- Curing

Cure speed can be accelerated with increased humidity and heat to very rapid cure times. Typical utilization involves dispensing in open air and after exposure to ambient humidity, a room temperature cured rubber is formed.</p> <p>Cure speed can be accelerated with increased humidity and heat to very rapid cure times. Typical utilization involves dispensing in open air and after exposure to ambient humidity, a room temperature cured rubber is formed.</p> <p>Cure speed can be accelerated with increased humidity and heat to very rapid cure times. Typical utilization involves dispensing in open air and after exposure to ambient humidity, a room temperature cured rubber is formed.</p> <p>Cure speed can be accelerated with increased humidity and heat to very rapid cure times. Typical utilization involves dispensing in open air and after exposure to ambient humidity, a room temperature cured rubber is formed.</p> <p>Cure speed can be accelerated with increased humidity and heat to very rapid cure times. Typical utilization involves dispensing in open air and after exposure to ambient humidity, a room temperature cured rubber is formed.

Solids

98% solidsAdhesion

Excellent unprimed adhesion to plastic, metal and glass

Packaging & Availability

- Packaging Type

Storage & Handling

- Storage

For maximum shelf life, keep containers sealed when not in use. Keep out of the reach of children. Uncured sealant irritates eyes and skin.

- Shelf Life

Sealed containers are guaranteed for 12 months from the ship date when stored in a cool dry area below 70°F.