Knowde Enhanced TDS

Identification & Functionality

- Active Component

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Tannin

Features & Benefits

- Product Highlights

Tan’Activ® GTH is a highly purified gallotannin offering a unique solution for both physical as well as organoleptic stability, produced in an ISO 22000 certified production facility.

- Key Benefits of Tannins in Beers

Physical and organoleptic stability and yield improvement:

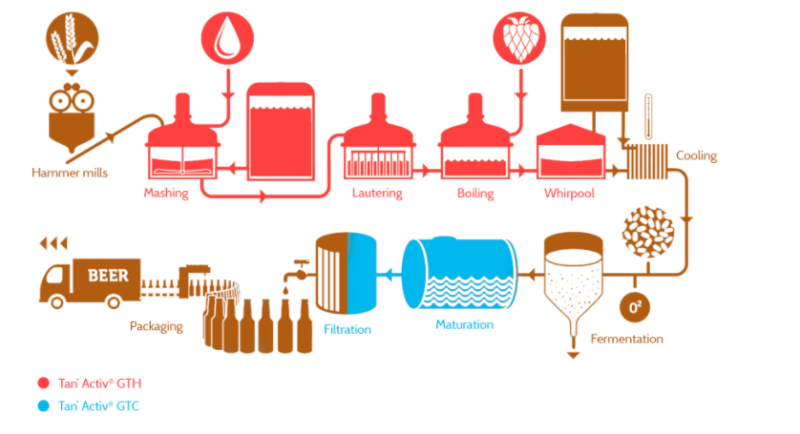

Tan’Activ® GT used at different stages in the process has the unique combined benefits for both colloidal - and organoleptic stability as well as possible improved process yields which are shown in below. The usage of Tan’Activ® GT, early in the process, permits to protect the taste stability while obtaining also some early colloidal stability and possible increased brewhouse performance.

Mashing-in:

- Reduction of LOX enzyme activity.

- Co-complexing of lipids.

- Reduction of certain aldehyde formation (e.g. phenylacetaldehyde, furfural, benzaldehyde).

- Metal ion co-complexing.

- Increased extract yield (fewer protein aggregates from thiol-containing proteins) up to 2%.

- Improved lautertun runoff rate (prevention of the formation of disulfide bridges, no formation of gels of ‘teig’) up to 30%.

- Early on protein correction in case of high protein malt (> 12%).

End of boiling / Transfer to whirlpool:

- Pre-colloidal stability.

- Reduction of metal ions e.g. Iron, Aluminum, Vanadium.

- Radical scavenging.

- Increase antioxidant potential, reduction of light struck effect.

- Protection of hop polyphenols and prolonged bitterness.

- Increased whirlpool performance, better hot trop separation, more compact cone, more clear wort.

- Fewer tank bottoms, shorter maturation time and longer filter runs.

- Reduction of cupper finings and stabilization processing aids.

Maturation:

- Good colloidal stability.

- Reduction of metal ions.

- Increased organoleptic stability.

End filtration:

- Very good colloidal stability.

- Most cost efficient stabilization processing aid.

- Prevention of uptake of Fe-ions with Kieselguhr filtration.

- Efficient filtration with perlite for Kieselguhr free filtration.

- Possible lingering aftertaste effects reduction.

- Virtually no waste.

Perceived improved final beer quality: final shelf life prolonged for extra months

- Prolonged stability of hop bitterness.

- Reduction of degradation of the unstable Trans-Iso alpha acids.

- Prolonged lag phase period of staling (40°C, 9 days ).

- Increased flavor Resistance Staling Value (RSV) of up to 30%.

- Lower Thiobarbituric Acid (TBA) values of up to 30% at 530nm (aldehydes).

- Very good Protein - Polyphenol values for beers with high pro-anthocyanidins in combination with PVPP.

- Clean and crisp taste!

- The Sustainable Solution

Tan’Activ® GT is a 100% natural product with raw materials abundantly available in several parts of the world. The small quantities of precipitates of the tannin-protein complex are completely removed after filtration and create the least amount of waste of all stabilization processing aids. Dosage levels are typically 30 to 40 times less than other widely used stabilization processing aids hence it has definitively the lowest CO2 footprint.

But above all these wonderful possible benefits for the beer, Tan’Activ® GT is perceived by the consumer as a natural process aid for its fresh, clean and crisp tasting physical stable beer, making it without any doubt the stabilization method of the future again.

Applications & Uses

- Markets

- Food & Nutrition Applications

- Application of Tannins & Dosages

Multiple production stages usage:

Tan’Activ® GT can be dosed at various stages of the brewery process. This subject to the objective of attaining more organoleptic stability, more colloidal stability, increased yields or a combination.

Tan’Activ® GT can be dosed at a single stage or at multiple stages, depending on the objective to achieve colloidal, organoleptic and/or process yield improvement effects. The dosing rates should be adjusted in accordance with the use of possible adjuncts and subject to a single stage - or multiple stages dosage.