Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Functional Group Structure

- -ОН One-Terminal

- Technologies

- Product Families

- Structure Model

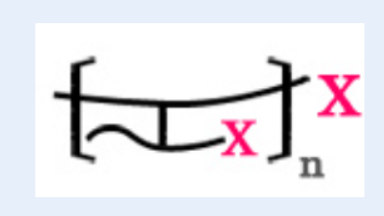

- Structural model of ACTFLOW® UMM-1001 Polymerization of terminal functional group type

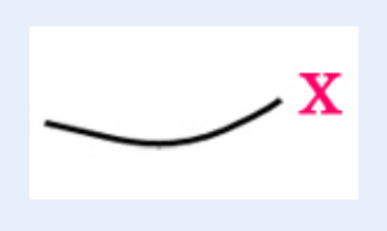

- Structural model of ACTFLOW® UMM-1001 Terminal functional group type

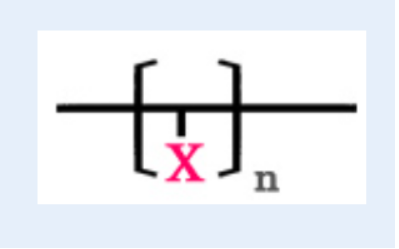

- Structural model of ACTFLOW® UMM-1001 Functional group co-polymerization type

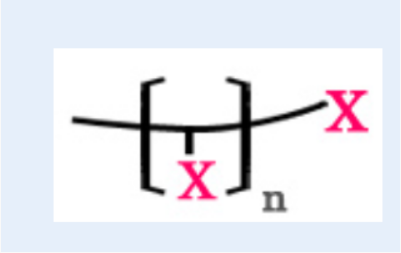

- Structural model of ACTFLOW® UMM-1001 Molecular ends and functional group co-polymerization type

Features & Benefits

- Materials Features

- Structural model of ACTFLOW® UMM-1001

Terminal functional group type

Since the functional group is introduced at the end of each molecule, this type of ACTFLOW® is effective when the number of functional groups must be adjusted independent of the molecular weight.Functional group co-polymerization type

A functional group can be introduced with relatively ease by co-polymerizing monomers that have the functional group. This type is effective for increasing the number of functional groups in a single molecule.Molecular ends and functional group co-polymerization type

This type combines the advantages of the molecular end and co-polymerization type. In addition, different types of functional groups can be combined to further enhance the performance.Polymerization of terminal functional group type

With the molecular structure containing multiple terminal functional groups having high reactivity and the molecular structure containing multiple branches, this type demonstrates the characteristics of the cross-linking component, compatibilizing component and thermosetting resin component.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Applications & Uses

ACTFLOW® can be effectively used as an additive agent to improve the alkali cleaning of resist materials and the removal of residue/sediment in photolithographic processes. Applications also recommend additives for color filter and dry film resist, and modifying agents for olefin, ABS and cellulose resin.

Using multifunctional acrylic polyol, ACTFLOW® is useful as the polyol component and cross-linking component for urethane film and sheets. It is also effective for adjusting the impact resistance property of ABS resin.By introducing the acrylic skeleton with excellent heat resistance and weatherability into urethane resins, ACTFLOW® effectively modifies and improves the physical properties of urethane-resin-based products.

Plasticizer and softening agent for various resins

ACTFLOW® is useful as the plasticizer for soft polyvinyl chloride. In particular, it has excellent storage stability, thermal sol performance, and "bleeding out of surface" at low temperature in the polyvinyl chloride sol process. In addition to polyvinyl chloride, ACTFLOW® has good compatibility with EVA and acrylic resins, and will effectively improve the low-temperature flexibility of acrylic sheets.Additive and modifying agent

ACTFLOW® is useful as the modifying agent for olefin resin and ABS resin. It can also be used to adjust the impact resistance properties of ABS resin, as well as to modify polyacetal resin and cellulose resin.Modifying agent for photolithography

By adding a small amount of liquid resin with high fluidity and high acid value, ACTFLOW® can be used effectively as an additive to improve the alkali cleaning of resist materials and the removal of residue/sediment in photolithographic processes. It is also useful as an additive for color filter and dry film resist.Base resin for film/sheets

Utilizing the excellent durability and transparency of the acrylic skeleton, ACTFLOW® is useful as the base resin for film or sheet. In particular, it is useful as the base resin for thermoplastic acrylic urethane as well as thermosetting acrylic silyl and acrylic urethane.Base polyol for polyurethane resin

Using multifunctional acrylic polyol, ACTFLOW® is useful as the polyol component and cross-linking component for urethane film and sheet. By introducing the acrylic skeleton with excellent heat resistance and weatherability into urethane resins, ACTFLOW® effectively modifies and improves the physical properties of urethane-resin-based products. This includes sealants, adhesives, urethane acrylate oligomers, paints, coating materials, films, sheets, and foams. Especially when used with HDI isocyanate prepolymer, ACTFLOW® will produce acrylic urethane film and sheet with excellent weatherability and heat resistance.

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Backbone | MA | — | — |

| Equivalent | 600 | g/eq | — |

| Molecular Weight (wt.) | average. 1000 | — | — |