Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Characteristics

- Cuts working time by up to 30 .

- Excellent initial bond, even at low temperatures.

- Economical in use due to precise application.

- One can covers up to 140 ft² of insulation.

- Suitable for vertical applications.

- Can be applied at temperatures between +23 °F and +95 °F.

- Thermal conductivity 0.035 W/m.K enhances performance of insulation panels when filling gaps.

- Remains flexible, does not become brittle.

- Levels uneven surfaces.

- Limited post expansion for fast and precise installation of insulation panels and plasterboard.

- Substantial space and weight savings compared to conventional PU roof adhesives, bonding mortars, etc.

- Fast curing, work can continue about 1 hour after application.

- Solvent-free.

- Resistant to a variety of solvents, paints and chemicals.

- Substrates

All usual substrates such as concrete, masonry, stone, plaster, wood, cold bituminous thick coatings, sand or slate surfaced bituminous sheeting, polystyrene, polyurethane and phenol resin foam, corrosion protected steel sheeting, fiber cement, gas concrete, particle board, plasterboard, gypsum fiberboard, fiber cement, hard PVC and emulsion paints.

Adhesive surfaces must be stable, clean, without bubbles and free of separating agents such as talcum, grease, oils, etc. Suitable are building moist, but not wet (water film, standing water) substrates. Any cement slurries and sinter layers on mineral substrates must be removed mechanically. Bubbles in bituminous sheeting must be removed. To ensure perfect adhesion, the bituminous sheeting should have a fully covered surface. Does not adhere to PE, PP. PTFE and silicone.

All substrates should be tested for suitability with regard to adhesion and compatibility.

Applications & Uses

- Markets

- Compatible Substrates & Surfaces

- Cure Method

- Applications

- Clean, efficient and economical permanent bonding of insulation panels.

- Suitable for bonding polystyrene (EPS + XPS), polyurethane (PUR/PIR) and phenol resin foam based insulation panels for flat roofs, perimeters, facades, insulation/drain elements, cellar ceilings, internal insulation, etc.

- Suitable for bonding gypsum plasterboard/gypsum fiberboard in dry lining applications.

- Suitable for bonding non-load bearing walls, e.g. partition walls, screen walls, cellar bars, stone shelves, etc., of concrete precision blocks (aerated concrete, sand-lime brick, gypsum, ...).

- Fills cavities between individual thermal insulation panels.

- Directions for Use

General

Prior to using the product, cover all adjacent areas for protection against soiling. In windy conditions, precautions must be taken to ensure that SOUDABOND EASY cannot contaminate components, objects or persons in the vicinity.

Good ventilation must be ensured for indoor use. Wear protective goggles and gloves. Tightly screw the can to the thread in the gun and shake the gun about 20 times downwards so that the contents are mixed well to ensure an optimum adhesive quality and high yield. After extended periods of non-use, the gun must be shaken again to obtain the required adhesive quality! With the adjusting screw on the gun, adjust the adhesive bead to the required diameter. (The emptier the can, the more the adjusting screw needs to be opened). The gun must be held vertical during application.

A distance of 0,4 to 0,8 inch must be maintained between the gun nozzle and insulation panel/substrate while spraying. Apply pressure to the insulation panel within about 8 minutes (68 °F - 65 % R.H. – this time is shorter at higher temperature/humidity and longer at lower temperature / humidity). Do not tap or remove and reapply panels as this will damage the adhesive structure and reduce the adhesive strength substantially. At high temperatures and low humidity in particular, curing can be accelerated by lightly spraying the adhesive bead with water.-

Bonding flat roof insulation materials

Apply SOUDABOND EASY directly to the substrate. Pressure should be applied to the insulation panels for optimal contact and maintained using suitable weights for at least 15 minutes to prevent lifting and slipping through wind suction. The panels must not be subjected to traffic for about 2 hours.

Consumption: At least three uniform adhesive beads with a minimum diameter of 1,2 inch are required per sqm adhesive surface. The number of adhesive strips, depend on the region, roof area, structure height, corner and edge areas as well as the materials to be bonded. The amount of adhesive to be applied depends on the wind load and must be increased in corner and edge areas.

2. Perimeter insulation

SOUDABOND EASY facilitates the installation of insulation panels in perimeter areas (Not suitable for pressing water!).

Spray SOUDABOND EASY from bottom to top with a bead spacing of about 1,2 inch (minimum three beads per continuous panel or minimum two beads for short panels!) on to the insulation panel or cellar wall. Press the insulation panel lightly against the cellar wall. Work from bottom to top without gap. The insulation panels must be bonded staggered in corners of buildings. The installed insulation panels can be readjusted with a long spirit level to correct any post expansion of the adhesive within 8 minutes.

The insulation achieves its final strength through the pressure of the filled soil, gravel or similar. Filling must take place within 14 days after bonding.3. Facade/wall insulation

SOUDABOND EASY is ideal for bonding insulation panels to interior walls and exterior facades!

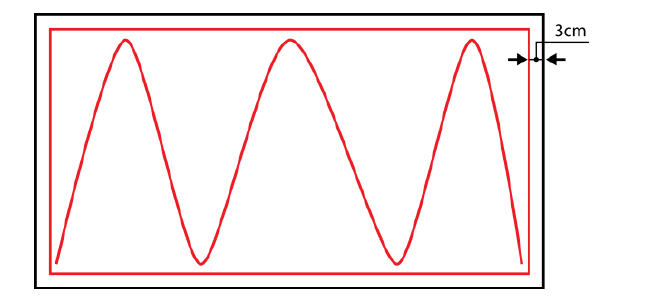

The gun must be held vertical during application. Apply a circular bead of SOUDABOND EASY to the insulation panel with enclosed M/W to cover an adhesive area of minimum 40% with pressure applied.

Wait at least 2 to maximum 8 minutes (68 °F / 65 % R.H.

– this time is shorter at higher temperature/humidity and longer at lower temperature/humidity) and subsequently press the insulation panel against the wall. Work from bottom to top without gap. Insulation panels must be bonded staggered in outer corners of buildings. Installed insulation panels can be adjusted with a long spirit level after 10 to 15 minutes to correct any post expansion of the adhesive. It is recommended to fix the last installed insulation panel during breaks.4. Cellar ceiling insulation

For working overhead, suitable protective goggles must be worn!

SOUDABOND EASY has a very high initial bonding strength and is therefore ideal for permanent bonding of insulation panels to cellar ceilings, garage ceilings or other overhead areas, also without additional mechanical fastening. Suitable are all standard insulation panels of polystyrene (EPS and XPS) and PUR/PIR measuring 20 x 20 inch with a maximum thickness of 4 inch and a maximum weight of 0,9 lbs.

Larger and heavier insulation panels and/or additional surfaces should be fixed mechanically within 15 minutes. This is easily done using ceiling supports for example.

Prior to application, the substrate stability must be verified. This can also take place with a sealing tape test.

In this test, sealing tape is applied to the substrate and quickly pulled off again. If old paint or plaster adheres to the adhesive tape, this means that the substrate does not have the necessary stability and must be reinforced or removed. With chalking and highly absorbent substrates, the substrate adhesion can be improved with a deep solvent primer. Protruding concrete burr must be removed mechanically.

At least one circular and one angular adhesive foam bead with a minimum diameter of 1,2 inch (about 0,09 lbf per panel) must be applied to each 20 to 20 inch panel. Do not apply the adhesive too close to the outer edges to avoid the excess going over the edges when pressure is applied to the insulation panel. Before bonding the insulation panel to the ceiling, SOUDABOND EASY must be allowed to stand for 3 to maximum 6 minutes to achieve the required initial strength. The insulation panel can subsequently be bonded to the ceiling. The panel must be placed carefully in the required position and pressure applied without tapping (damages the adhesive structure). The next insulation panel must be bonded 5 minutes after the previously bonded panel so that it remains in place when the next panel is bonded. Insulation panels must be additionally fixed in the center with a suitable insulation anchor under unfavorable bonding conditions.5. Interior insulation/dry lining

Prior to application, the substrate stability must be verified. This can also take place with a sealing tape test. In this test, sealing tape is applied to the substrate and quickly pulled off again. If old paint or plaster adheres to the adhesive tape, this means that the substrate does not have the necessary stability and must be reinforced or removed. With chalking and highly absorbent substrates, the substrate adhesion can be improved with a deep solvent primer. Remove protruding concrete burr or excess plaster. SOUDABOND EASY levels uneven surfaces up to 1,2 inch.

Interior insulation panels:

Apply SOUDABOND EASY about 0,8 inch away from the edge of the panel as a 1,2 inch circular bead and to the panel surface in lines or a W-shape. It must be ensured that the adhesive contact area is about 40% after applying pressure. The adhesive must always be applied circular also for panel cut-outs, penetrations, etc., to prevent rear circulation of the interior insulation. After applying SOUDABOND EASY, depending on the climatic conditions, allow to flash off for about 3 - 6 minutes. This ensures that an optimal adhesive strength is achieved with reduced post expansion. Subsequently place the insulation panel on wedges, align and apply pressure from bottom to top. Do not tap or remove the panels as this can reduce the adhesive strength substantially. Apply new adhesive if necessary. After about 6 to 10 minutes, check for correct seating, readjust with a spirit level/level. Edges of walls, ceilings and floors, openings and penetrations must be filled out completely with SOUDABOND EASY air-tight and sound insulated. Work can be continued after minimum 1 hour.Plasterboard:

In contrast to interior installation, three vertical adhesive beads are sufficient for the installation of plasterboard wider than 20 inch. For panel widths below 20 inch, a minimum of two adhesive beads must be applied.6. Concrete precision block bonding

SOUDABOND EASY must not be used for components requiring approval, e.g. supporting walls and walls relevant for safety!

Good ventilation must be ensured for indoor use! Clean the adhesive surfaces, remove lose particles and moisten. Apply two SOUDABOND EASY adhesive beads with a diameter of about 1,2 inch to the substrate and subsequently to all further concrete precision blocks. The adhesive beads must be applied about 2 inches away from the stone edge parallel on horizontal and vertical joints. Position/join and align bricks within minimum 2 to maximum 8 minutes (68 °F / 65 % R.H. – this time is shorter at higher temperature/humidity and longer at lower temperature/humidity). If once joined bricks are removed, new adhesive beads must be applied. Allow excess adhesive to cure and subsequently remove, e.g. with a spatula. Depending on the ambient temperature, work can be continued after minimum 60 minutes. The adhesive achieves full strength after minimum 12 hours.-

- Other applications

- Due to its excellent adhesive properties, reduced foaming and fast final strength, SOUDABOND EASY is

- suitable for numerous bonding applications. SOUDABOND EASY is ideal for the installation of insulation panels in building and construction. Installation of loft insulation reveals and claddings as well as bonding of wall edging strips are just a few examples.

- General note: Do not load/subject the bond to traffic within the curing time of about 2 hours! All open joints within the insulation can be filled out with SOUDABOND EASY. Trim protruding, fully cured adhesive with a sharp knife. SOUDABOND EASY can be painted or plastered after curing.

- Application temperature:

- +23 ºF to +95 ºF (adhesive surface temperature)

- +41 °F to +77 °F (can temperature) – optimal +59 °F to +77 °F

- If required, slowly bring the can to the optimal temperature by placing in cool or warm water.

- Cleaning: with GUN & FOAM CLEANER or SWIPEX prior to curing, subsequently with PU REMOVER or remove mechanically

- Repair option: with SOUDABOND EASY

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Base | Single component polyurethane | - | - |

| Can Be Trimmed (1.2 Inch Adhesive Bead) | 50.0 | minutes | - |

| Consistency | Stable adhesive foam (does not sag) | - | - |

| Curing Speed (Genius Gun Foam, 1.2 Inch Adhesive Bead) | 45.0 | minutes | - |

| Curing Speed (Gun Foam, 1.2 Inch Adhesive Bead) | 30.0 | minutes | - |

| Curing System | Moisture cure at room temperature | - | - |

| Fire Test | Flame Spread 15. Smoke Developed 35 | - | UL 723 ASTM E 84 |

| Full Strength (1.2 Inch Adhesive Bead) | 12.0 | hrs | - |

| Post Expansion | Minimal | - | - |

| Shear Strength | 20.6 | lbf/in² | - |

| Skin Formation (1.2 Inch Adhesive Bead) | 8.0 | minutes | - |

| Temperature Resistance (248°F, Up to Max. 1 Hour) | -40 to +194 | °F | - |

| Tensile Strength | 27.6 | lbf/in² | - |

| Thermal Conductivity | approx. 0.035 | W/(m∙K) | DIN 52612 |

Regulatory & Compliance

- Standards and Approvals

UL 723 (ASTM E 84)

Safety & Health

- Safety Recommendation

Observe the standard industrial hygiene procedures. Wear protective goggles and gloves. Remove cured adhesive mechanically, never remove with a flame.

Packaging & Availability

- Packaging

24 oz aerosol can (12 per box)

Storage & Handling

- Shelf Life

18 months from date of production in unopened packaging with cool (41 °F to 77 °F) and dry storage.