Knowde Enhanced TDS

Identification & Functionality

- Technologies

Features & Benefits

- Product Highlights

- Fluorescent leak detection dyes for synthetic and petroleum-based fluid systems.

- Works in closed-loop circulatory systems where oil-based fluids are used.

- Engineered to work with any host fluid without damaging the fluid’s properties or any of the system’s components.

- Ideal for lubricant and hydraulic leaks.

- Some applications include: facility maintenance and machinery, mobile hydraulic equipment, stationary hydraulic equipment, oem on-line quality control.

- Features

- Fully Miscible - High Quality, non-particulate and filtered down to 2 microns. Won’t change the viscosity or lubricity of host fluid.

- Exclusive Formula - Engineered to meet manufacturers’ specifications.

- Improved Stability - More tolerant to extreme temperature range & moisture.

- Independently Tested - For system compatibility & will remain safely within the system.

Applications & Uses

- Applications

- Works With

Product Works With Fluorescent Color

SPI-OGYG UV/Blue Light/Violet Light Yellow-Green - Directions

- Add the appropriate OIL-GLO® ULTRA dye to the suspect system. Begin with the recommended dilution ratios of dye to host fluid. More dye can be added to the system if leaks are not clearly visible.

- Run the system to allow the OIL-GLO® ULTRA dye to circulate thoroughly. The dye needs time to mix with the oil and circulate to all the leak sites. This period of time will vary greatly depending on the size of the system and the size of the leak. It could take anywhere from 5 to 10 minutes for small systems with large leaks, to several days for larger systems with smaller leaks.

- Inspect all areas with a high intensity Spectroline® lamp. Be sure to use the fluorescence-enhancing glasses supplied with the lamp, especially when using a blue light lamp. In hard to reach areas, use a mirror to reflect the light, or wipe the obstructed area with a clean cloth, and then check for the fluorescence. NOTE: For best results, use the lamp in low-light conditions.

- OIL-GLO® ULTRA can safely remain in the system, so you can check the repair without adding more dye.

- After the leaks are repaired, clean the leak sites with Spectroline® GLO-AWAY™ PLUS dye cleaner or a shop cleaner.

- Run the system again and reinspect with the lamp. No glow means all leaks have been fixed!

Host Fluid 1 oz dye (30 ml) per application

Light-colored hydraulic fluid 8 gal (30 I) Dark or intensely blue hydraulic fluid 4 gal (15 ) Compressor oil 4 gal (15 ) Engine oil 3 gal (11 I) Gearbox oil 1 gal (3.8 ) - Uses

Use as part of a diagnostic/preventive maintenance program.

- Cooling control & hydrostatic pressure systems

- Cooling towers

- Generator engines

- Hydraulic systems

- Liquid holding tanks

- Pipelines

- Turbines

- Applications

- Light-colored hydraulic fluid

- Dark/intensely blue hydraulic & lubrication fluids

- Compressor oil

- Engine oil

- Gearbox oil

- Fuel (gasoline or diesel)

Use with

- UV Lamp + UV-Absorbing, or

- Violet Light Lamp + Fluorescence- Enhancing

Regulatory & Compliance

- Certifications & Compliance

- Certification

NSF Certified—OIL-GLO® ULTRA series fluorescent dyes are registered to meet food-grade processing requirements for category codes HTX-2 and HX-2.

Technical Details & Test Data

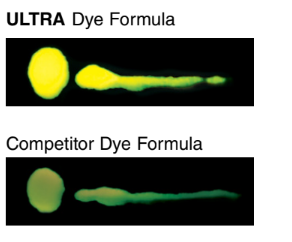

- Spectroline® dyes glow brighter than the competition.

Works in both static & circulating systems.

Safety & Health

- Note

- Keep out of reach of children.

- Wash thoroughly after handling.

- Wipe all spills to avoid stains.

- Store in a cool place away from sunlight.

- Store in climate controlled, dry area.

- Dispose of in accordance with all local, state and federal regulations.

Packaging & Availability

- Packaging Type

- Available In

6 packs of 1-oz bottles, in 8-oz bottles, in 16-oz bottles, and 1-gal, 5-gal and 55 gal (209 L) containers.

Storage & Handling

- Shelf Life

Improved Shelf Life - Up to 5 years.