Knowde Enhanced TDS

Identification & Functionality

- Pigment Type

- Technologies

Features & Benefits

- Product Highlights

- Quickly pinpoint the exact source of all water leaks including tiny, evaporated and condensation-covered leaks.

- Works in both static and circulating systems.

- Can be used as a diagnostic tool for testing seams, welds, seals, fittings and flow-rate measuring.

- Ideal for heat transfer fluid systems.

- Some applications include: boilers, heaters/ pumps, sprinkler systems, storage tanks.

- Features

- Fully Miscible - High Quality, non-particulate and filtered down to 2 microns. Won’t change the viscosity or lubricity of host fluid.

- Exclusive Formula - Engineered to meet manufacturers’ specifications.

- Improved Stability - More tolerant to extreme temperature range & moisture.

- Independently Tested - For system compatibility & will remain safely within the system.

Applications & Uses

- Applications

- Works With

Product Works With Fluorescent Color

SPI-WGG UV/Blue Light/Violet Green - Directions

- Add the dye to the suspect system. Begin with the recommended dilution ratio of dye to water. Use 1 pt (473 ml) of SPI-WGB dye for every 500 gal (1,900 l) of water in the system. Use 1 pt (473 ml) of SPI-WGG dye for every 1,000 gal (3,800 l) of water in the system. More dye can be added to the system if the leaks are not clearly visible.

- Operate or pressurize the system to ensure adequate circulation of the dye. For static systems, mix thoroughly with the water.

- Inspect all areas with a high-intensity Spectroline lamp. Be sure to use the fluorescence-enhancing glasses, or the UV-absorbing glasses supplied with the lamp. A bright fluorescent glow will be visible at the site of the leaks and along the leakage path. (Note - For best results, use the lamp in low-light conditions.)

- For suspect areas obstructed from view, wipe the area with a clean white cloth and then check for the fluorescence.

- The dyes may safely remain in the system, so you can check the repair without adding more dye.

- After the leaks are repaired, clean the leak sites with Spectroline® GLO-AWAY™ PLUS dye cleaner or a general-purpose shop cleaner.

- Run or pressurize the system again and reinspect with the lamp. No glow means all leaks have been fixed!

- Uses

- Geothermal Heat Pump Systems

- HVAC Systems

- Solar Systems

- Boilers

- Chillers

- Dryers/Kilns

- Open Baths

- Reactors

Properties

- Color

Regulatory & Compliance

- Certifications & Compliance

- Certification

NSF Certified: WATER-GLO® ULTRA series fluorescent dyes are registered to meet food-grade processing requirements for category codes G-7, GX and HTX-2.

Technical Details & Test Data

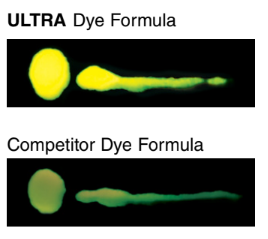

- Spectroline® dyes glow brighter than the competition.

Works in both static & circulating systems.

Safety & Health

- Note

- Keep out of reach of children.

- Wash thoroughly after handling.

- Wipe all spills to avoid stains.

- Store in a cool place away from sunlight.

- Store in climate controlled, dry area.

- Dispose of in accordance with all local, state and federal regulations.

Packaging & Availability

- Packaging Type

- Available In

1-pint (473 ml) bottle, as well as 1-gallon (3.8 l), 5-gallon (19 l) and 55-gallon (208 l) containers. Available in two colors.

Storage & Handling

- Shelf Life

Improved Shelf Life - Up to 5 years.