Knowde Enhanced TDS

Identification & Functionality

- Cleaning Ingredients Functions

- Industrial Additives Functions

- CAS No.

- 68410-69-5

- EC No.

- 688-441-0

- Product Families

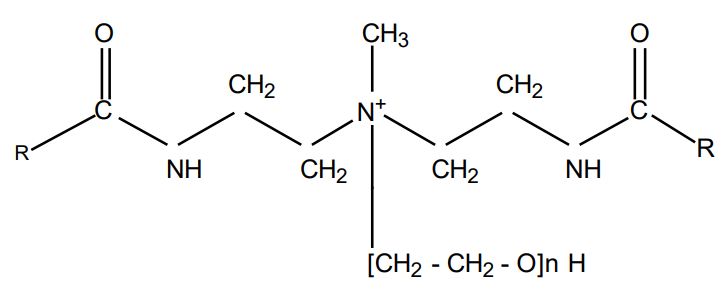

- Chemical Structure

CH3OSO3- R = Tallow

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Home Care Applications

- Industrial Additives End Use

- Recommended Applications

ACCOSOFT 501 is a fabric softener quaternary for use in household and commercial products. It can be used in a full range of dispersion concentrations with excellent storage stability and easy formulation. ACCOSOFT 501 will produce 2.5 - 25% solids dispersions with a minimum of electrolyte. These dispersions exhibit instant cold water dispersibility. ACCOSOFT 501 offers good rewet and is non-yellowing.

- Recommendations

No. 316L Stainless Steel centrifugal or positive displacement pumps should be used. Piping should be of No. 316L Stainless Steel, Schedule 40 or Steel Kynar lined P.V.F. Rubber hoses lined with Teflon or crosslinked polyethylene and equipped with No. 316L Stainless Steel fittings are recommended for loading and unloading. Contact with brass, copper, and aluminum components must be strictly avoided.

Properties

- Physical Form

- Appearance

- Opaque fluid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Color | max. 3 | — | Gardener Scale |

| Density | 0.97 | g/ml | — |

| pH (10% in 50:50 water:IPA) | 6 | — | — |

| Flash Point | 24 | °C | PMCC Flash Point Tester |

| Solids Content | 88 | wt% | — |

| Pour Point | 20 | °C | — |

| Minimum Handling Temperature | 27 | °C | — |

| Viscosity (MHT) | 1400 | cPs | — |

| Regulated Volatile Organic Chemicals (Isopropanol) | 12 | % | U.S. EPA |

Regulatory & Compliance

Safety & Health

- Toxicity

ACCOSOFT 501 is practically non-toxic orally (LD₅₀ > 20 g/kg) and causes no eye irritation 21 days post dosing. It is minimally irritating to skin and is not a skin sensitizer.

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace safety practices should be used to control these exposures.

Packaging & Availability

- Standard Packaging

ACCOSOFT 501 is available in drums (425 lb, 193 kg) or bulk quantities.

Storage & Handling

- Storage & Handling

- Handle ACCOSOFT 501 with care; use away from sparks and open flame. Use in a well ventilated area. Contact with the eyes and prolonged contact with the skin should be avoided. Use gloves and safety goggles when handling ACCOSOFT 501.

- The color and odor of ACCOSOFT fabric softener quaternaries are susceptible to degradation as a result of exposure to high temperatures, particularly in the presence of air. ACCOSOFT 501 contains sodium bisulfite as an antioxidant to preserve color. Successful long-term storage, in liquid form, depends on maintaining a sodium bisulfite level of 200-1000 ppm. Methods for monitoring are available from Stepan Company.

- It is recommended that ACCOSOFT 501 be stored in stainless steel storage tanks of type 304L minimum, 316L is preferred. Also acceptable are Fiber Reinforced Plastic (FRP) with an Atlac 382 type lining. Tanks should be padded with a nitrogen gas blanket and equipped with conservation vents and flame arrestors. Tanks should be adequately insulated to maintain elevated temperatures. Generally, mixing is recommended to maintain homogeneity, either by a mechanical stirrer or recirculation loop.

- Bulk storage facilities should be designed to maintain a minimum product temperature of 27°C (80°F) and a maximum temperature of 52°C (125°F). Hot water heating provided through No. 316L Stainless Steel heating coils is recommended. Steam heating through coils can be used.