Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Agrochemical Functions

- Cleaning Ingredients Functions

- Industrial Additives Functions

- CAS No.

- 25155-30-0

- EC No.

- 246-680-4

- Product Families

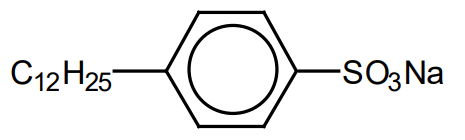

- Chemical Structure

Features & Benefits

- Labeling Claims

- Agrochemicals Features

- HII Features

- Biodegradability

Product is readily biodegradable.

Applications & Uses

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Applications

Linear alkylbenzene sulfonates (LAS) are the workhorses of the household, industrial and institutional detergent industries. Stepan's BIO-SOFT D sulfonates are the proven choice for many applications. They provide superior detergency, foaming, wetting and emulsification properties --and all at an economical cost. Stepan's continuous falling film sulfonation process assures high quality, excellent color, low odor and minimum salt content. BIO-SOFT D sulfonates are available in several forms and concentrations to meet your handling and formulating needs. BIO-SOFT D surfactants are used in laundry and dishwashing detergents, all-purpose cleaners, vehicle cleaning compounds and heavy duty commercial and industrial cleaners as well as industrial applications requiring special surface active properties. BIO-SOFT D sulfonates contain hydrotrope for ease of handling.

Properties

- Formulation Type

- Appearance

- Slurry (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH (10% in aqueous solution) | 8 | — | — |

| Density | 1.09 | g/ml | — |

| Actives Content | 55 | % | — |

| Solids Content | 62 | wt% | — |

| Freeze Point | -1 | °C | — |

| Pour Point | 2 | °C | — |

| Color (in 5% solids) | 40 | — | Klett Colorimeter |

| Viscosity (at 0°C) | Solid | cPs | — |

| Viscosity (at 25°C) | 8000 | cPs | — |

| Viscosity (at 60 °C) | 2200 | cPs | — |

| Flash Point | min. 94 | °C | PMCC Flash Point Tester |

| Regulated Volatile Organic Chemicals | 0 | % | U.S. EPA |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

- All components of BIO-SOFT D surfactants are listed in the following countries; the registration numbers for the active ingredients are included in parentheses: United States (TSCA 68081-81-2), Australia (AICS 68081-81-2), Canada (DSL 68081-81-2), China (IECSC 68081-81-2), Europe (EINECS 268-356-1), Japan (ENCS 3-1949), Korea (ECL Serial No. KE-02630), New Zealand (NZIoC 68081-81-2), and Philippines (PICCS 68081-81-2).

- BIO-SOFT D-62 LT meet U.S. EPA Safe Choice Program’s surfactant screen.

- The BIO-SOFT D series is USDA authorized.

Safety & Health

- Toxicity

Linear alkylbenzene sulfonates (LAS) are moderately to slightly toxic orally (LD₅₀ = 400 - 2000 mg/kg); and cause no skin irritation at 1% concentration. LAS causes mild to no eye irritation at below 0.1% concentration.

Packaging & Availability

Storage & Handling

- Storage & Handling

- As with most surfactants, it is recommended that normal safety precautions (i.e., use of gloves and safety goggles) be followed when handling BIO-SOFT D series products.

- Recommended Storage Conditions: The BIO-SOFT D series should be stored in closed containers in a cool, dry place. BIO-SOFT D-62 LT stored in drums should be stirred prior to use to ensure homogeneity. Frozen material should be heated gently and stirred to ensure it is homogeneous before use.

- Bulk Storage Recommendations: The BIO-SOFT D series should be stored in 316 stainless steel or fiberglass with a corrosion liner. Mild agitation is recommended while storing to maintain homogeneity. Material should be stored between 85-105 °F (29-40 °C). An internal hairpin coil constructed of 316 stainless steel with low pressure steam (under 50 psig) should be used if heating is required. Pumps, pipes and transfer lines should be 316 stainless steel.

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace practices should be used to control these exposures.