Knowde Enhanced TDS

Identification & Functionality

- Agrochemical Functions

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- CAS No.

- 127087-87-0

- EC No.

- 500-315-8

- Technologies

- Product Families

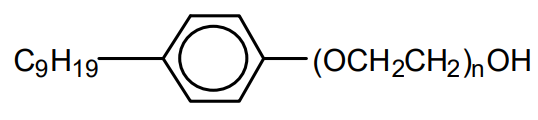

- Chemical Structure

- Surfacant Type

Non-ionic

- Surfactant Type

Nonionic.

Features & Benefits

- Benefit Claims

- Labeling Claims

- Agrochemicals Features

- HII Features

- Biodegradability

MAKON 12 is biodegradable.

Applications & Uses

- Applications

- Applicable Processes

- Application Format

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Hair Care Applications

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Applications

MAKON 12 surfactants are nonionic in nature; they neither ionize in water nor hydrolyze in aqueous acid or alkaline solutions. Chemically, they are the reaction products of nonylphenol and ethylene oxide. They differ in the mole ratio of hydrophilic ethylene oxide to hydrophobic nonylphenol. The MAKON surfactants are high active products that offer a broad range of properties. Because of this versatility, MAKON products find application in a number of different industries and in a multitude of products including agricultural emulsions, detergents, sanitizers, industrial cleaners, metal cleaners, textiles, paper de-inking and drilling products.

Properties

- Formulation Type

- Physical Form

- Appearance

- Hazy liquid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| pH (5% in 1:1 IPA:H₂O) | 7.5 | — | — |

| Actives Content | 99.8 | % | — |

| Color | max. 100 | — | Apha Scale |

| Density | 1.06 | g/ml | — |

| Freeze Point | 11 | °C | — |

| Cloud Point (1% in water) | 81 | °C | — |

| Hydroxyl Number | 76 | — | — |

| HLB | approx. 14 | — | — |

| Average Number of Moles of Ethylene Oxide | 12 | — | — |

| Pour Point | 14 | °C | — |

| Viscosity (at 25°C) | 280 | cPs | — |

| Flash Point | min. 94 | °C | PMCC Flash Point Tester |

| Regulated Volatile Organic Chemicals | 0 | % | U.S. EPA |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

- MAKON 12 is listed in the following countries; the registration numbers for the active ingredients are included in parentheses: United States (TSCA 127087-87-0), Australia (AICS 127087-87-0), Canada (DSL 127087-87-0), China (IECSC 127087-87-0), Europe (NLP 500-315-8), Japan (ENCS 7-172), Korea (ECL Serial No. KE-26246), New Zealand (NZIoC 127087-87-0), and Philippines (PICCS 127087-87-0). It is the responsibility of the end user to review the chemical control regulations for each country.

- MAKON 12 is available as Kosher certified.

Safety & Health

- Health Effects

MAKON products are slightly to practically non-toxic orally (LD50 > 1400 mg/kg). Undiluted MAKON products are moderately to severely irritating to eyes, while concentrations of 25% or less are minimally irritating to eyes.

Packaging & Availability

- Standard Packaging

MAKON 12 is available in drums (475 lb, 215 kg) and in bulk quantities.

Storage & Handling

- Storage & Handling

Normal safety precautions (i.e. gloves and safety goggles) should be employed when handling MAKON surfactants. Contact with the eyes and prolonged contact with the skin should be avoided. Wash thoroughly after handling material. It is recommended that MAKON products be stored in sealed containers and kept in a cool, dry place. If material is frozen it should be heated gently and stirred to ensure it is homogeneous before use.

Bulk Storage Information

MAKON surfactants can be stored in vessels of 316 stainless steel, but carbon steel is adequate. Material should be stored between 100 - 110 °F. An internal hairpin coil of carbon steel with low pressure steam (under 50 psig) should be used if heating is required. Mild agitation is required if the tank is heated. Material is heat sensitive and agitation prevents localized heating. Heating may not be required for inside storage if the tank is turned over frequently. Stainless steel 316 is preferred for pumps, pipes and transfer lines; however, carbon steel is adequate.

- Workplace Exposure

Occupational exposure can occur primarily through skin contact or via inhalation of vapors and mists. Engineering controls, personal protective equipment, and other workplace practices should be used to control these exposures.