Knowde Enhanced TDS

Identification & Functionality

- Agrochemical Functions

- Technologies

Features & Benefits

- Agrochemicals Features

- Product Features & Benefits

At the recommeded use of 0.25 - 0.50% per 100 gallons STEPGROW CT:

- Acts as an acidifying agent to reduce pesticide decomposition and boost efficacy

- Lowers the pH of the tank solution to prevent alkaline hydrolysis

- Enables uniformity of the pesticide solution to maximize crop protection dollars

- Optimizes compatibility to prevent undesired precipitation that can lead to plugging of sprayer lines

Applications & Uses

- Markets

- Application Technique

- Applications

STEPGROW CT is a compatibility agent designed for liquid fertilizers and pesticides, as well as combinations of two or more pesticides in a single spray application.

Properties

- Formulation Type

- Physical Form

- Appearance

- Clear amber liquid (at 25°C)

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Actives Content | 100 | % | — |

| Color | max. 6 | — | Gardner Scale |

| Density (at 25°C) | 1.12 | g/ml | — |

| Flash Point | min. 94 | °C | PMCC Flash Point Tester |

| Freeze Point | -24 | °C | — |

| pH (in 1:1 H₂O:IPA) | 2.5 | — | — |

| Viscosity (at 25°C) | 2200 | cPs | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- Clearances

- The international inventories (country clearances) of STEPGROW CT can be found in Section 15 of the Safety Data Sheet (SDS). It is the responsibility of the formulator to review the chemical control regulations for each country where the end product is intended to be sold or used.

- STEPGROW CT is approved for use as an inert ingredient under U.S. EPA 40 CFR 180.910 and U.S. EPA 40 CFR 180.930.

Technical Details & Test Data

- Suspension Concentrate Diluted 100% in 8-16-8 Fertilizer

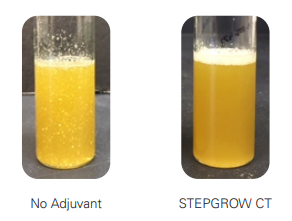

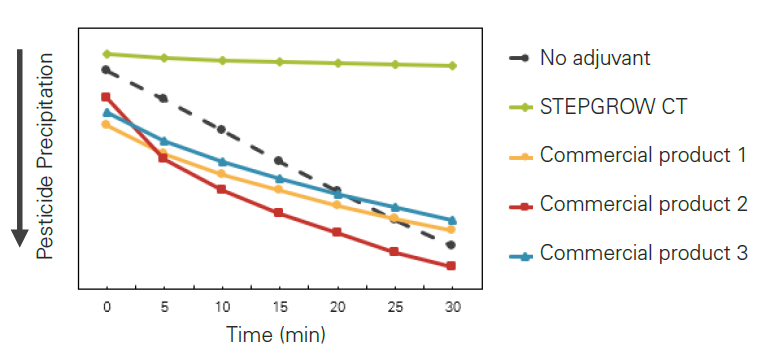

Dilution of suspension concentrate in an 8-16-8 fertilizer causes immediate flocculation that settles out over the course of 30 minutes. The images and graph below demonstrate how the addition of STEPGROW CT allows the pesticide to stay suspended in the solution and remain stable, while three commercially available adjuvants are unable to prevent pesticide precipitation.

Initial Mixture

Stability Tracking of Static Mixture

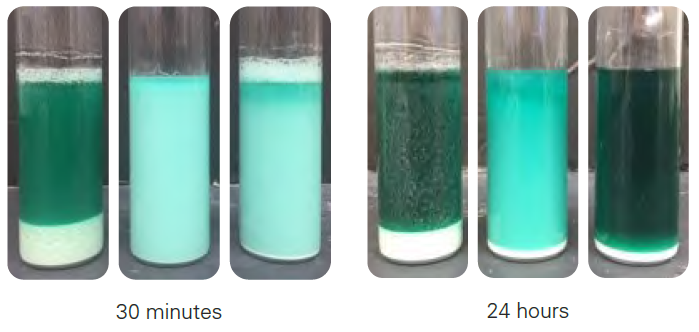

- Tank Mix of Suspension Concentrates and Soluble Liquid Products

The tank mix of suspension concentrates and soluble liquid products separates immediately. The images below show how the addition of a commercially available adjuvant improves short-term performance. STEPGROW CT has superior initial stability and maintains pesticide suspension in solution, enabling long-term stability up to 24 hours.

Left: No Adjuvant

Center: STEPGROW VCT

Right: Commercial Product

Packaging & Availability

- Standard Packaging

STEPGROWCT is available in drum and bulk quantities.

Storage & Handling

- Storage & Handling

- Normal safety precautions (i.e., gloves and safety goggles) should be employed when handling STEPGROW CT. Contact with eyes and skin should be avoided. Wash thoroughly after handling materials. See the Safety Data Sheet (SDS) for further information.

- Bulk Storage Recommendations: Elevated storage temperature may be desirable to maintain ease of pumping, but the product should be stored at ambient temperature.

- Non-Bulk Storage Recommendations: STEPGROW CT which has been stored in drums at temperatures below -11°F (-24°C) may thicken or solidify. It may be fluidized by warming with a drum heater or in a steam room. Drums should be vented prior to heating to avoid excessive pressure build up. Product temperatures over 130°F (54°C) are not recommended.