Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Food Ingredients Functions

- Ingredients

- Protease, Soy Flour, Tricalcium Phosphate, Wheat Starch, Xylanase

- Technologies

Features & Benefits

- Food Ingredients Features

Applications & Uses

- Markets

- Applications

Properties

- Appearance

- Powder

- Odor

- Flour-like slightly fermented

- Chemical Properties

- Typical Properties

- Nutritional Information

- Nutritional Data

Description Value Unit/100g Energy 1.467 kJ Energy 340 kcal Fat 0.4 g of which: saturated fatty acids (FA) 0.08 g Carbohydrates 79.16 g of which: Sugar 0.9 g Fiber 0.38 g Protein (N x 6,25) 5.97 g Salt (Sodium x 2.5) 0.892 g Sodium 0.357 g - The nutritional information is calculated according to EC regulation 1169/2011.

- The nutritional data presented are typical values.

| Value | Units | Test Method / Conditions | |

| Arsenic Content | max. 3 | mg/kg | AAS |

| Cadmium Content | max. 0.5 | mg/kg | AAS |

| Lead Content | max. 10 | mg/kg | AAS |

| Loss on Drying | max. 14 | g/100g | §64 LFGB-2h 130°C |

| Mercury Content | max. 0.5 | mg/kg | AAS |

| Value | Units | Test Method / Conditions | |

| Protease | 250 - 310 | u/g | Casein hydrolysis pH 8 |

| Value | Units | Test Method / Conditions | |

| Energy | 1.467 | kJ/100 g | — |

| Fat Content | 0.4 | g/100g | — |

| Saturated Fatty Acids | 0.08 | g/100g | — |

| Carbohydrates | 79.16 | g/100g | — |

| Sugar | 0.9 | g/100g | — |

| Fibre | 0.38 | g/100g | — |

| Protein (N x 6.25) | 5.97 | g/100g | — |

| Salt (Sodium x 2.5) | 0.892 | g/100g | — |

| Sodium Content | 0.357 | g/100g | — |

Regulatory & Compliance

- Certifications & Compliance

- Regulatory Information

Allergen Information: contains the allergen gluten and soy according to Regulation 1169/2011/EG, Annex II

Health Information: The products are suitable for human consumption if used accordingly to recommendations and officially allowed to be sold within Germany and the EU. The product is food grade and conforms with the current european food law.

GMO: This product is not a genetically modified organism (GMO), nor does it contain any GMO or any recombinant DNA. All the non-enzymatic constituents of the product (e.g. carriers, stabilizing agents, free-flowing agents etc.) originate from non-genetically modified sources. Due to the ubiquitous presence of GMO organisms, absence of minor traces of GMO material cannot be guaranteed, but in any case, the content of unintentionally present GMO material will be below 0.9%, in accordance to EU guidelines 1830/2003 and 1829/2003. The product is used as processing aid in food manufacturing processes, and therefore labeling is not required in the EU. National regulations must be observed.

Product suitability:

Yes No Vegetarian X Vegan X BSE/TSE Information: The mentioned product does not represent a BSE (Bovine Spongiform Encephalopathy) and/or TSE (Transmissible Spongiform Encephalopathy) risk.

Irradiation: Neither the product nor its ingredients have been treated with ionizing radiation according to Directive 1999/2/EC and 1999/3/EC.

Nanoparticles: The product does not contain ingredients in the form of engineered nanomaterials as defined in Regulation (EU) 2015/2283.

Contamination/Residues: The product complies with: Regulation (EC) No 396/2005 and its amendments regarding maximum levels for pesticide residues in foodstuffs. Regulation (EC) No 1881/2006 and its amendments regarding especially maximum levels for heavy metals, mycotoxins, dioxins and PCB in foodstuffs.

Conformity of the Packaging: The packaging material complies with the provisions of Regulation (EC) No 1935/2004 and Regulation (EU) No 10/2011.

Technical Details & Test Data

- Application Note

- Utilization of high extraction flours

- Homogeneous wafer batters for an improved processibility

- Reduced viscosity for a trouble-free production

- Reduced water addition for energy savings

In an increasingly competitive environment, margins are always under pressure. Profitability is greatly enhanced by even marginal improvement of flour yields, resulting in a competitive advantage. The target is to achieve maximum flour yield with acceptable flour ash and quality, without compromising the production rate. However, higher flour yield is often associated with an increased ash content in flour, making it inferior for wafer production. In this case Sternzym LQ 15080 is the best option to ensure a consistent product quality, even with poorer flour qualities, enabling a continuous and trouble-free production.

Production of wafers with high extraction flour

Ingredients (kg) Control with Sternzym LO 4020 Trial with Sternzym LO 15080 Water 126.00 131.25 Salt 0.42 0.42 Sodium bicarbonate 0.37 0.37 Soy lecithin 0.53 0.53 Palm oil 1.05 1.05 Ammonium bicarbonate 0.11 0.11 Egg white powder 5.25 5.25 Wheat flour (0.79% ash) 100.00 100.00 Enzyme 0.05 0.03 Batter temperature: 24-25 °C Fermentation time: 15-20 minutes High extraction flour contains more material from the bran layers, including a high amount of non-starch polysaccharides (NSP) such as pentosans. This causes a drastic increase in the wafer batter viscosity, making it difficult to process.

For instance, using a flour with 0.79 % ash results in a very high batter viscosity, making it barely workable on the wafer machine. The result is an incomplete wafer sheet, even when using Sternzym LQ 4020 (see Fig. 1).

For processing high extraction flour, Sternzym LQ 15080 is best suited due to its strong cellulase and hemicellulase activity. Thus, this enzyme system efficiently hydrolyses NSP and hence mitigates viscosity related production problems. The distinctly reduced viscosity enables the production of high-quality wafer sheets (see Fig. 2).

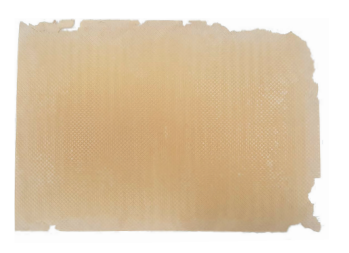

Fig. 1: Incomplete wafer sheet produced from a high viscosity batter ( > 3 min through the flow funnel) treated with the precursor enzyme Sternzym LQ 4020

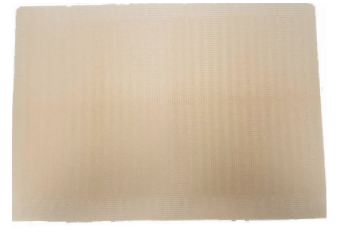

Fig. 2: High quality wafer sheet produced from a batter with a distinctly reduced viscosity (approx. 57 s through flow funnel) as a result of the treatment with Sternzym LQ 15080

Packaging & Availability

- Packaging Type

- Packaging

Cardboard box with PE inliner, 25 kg net

Storage & Handling

- Storage & Shelf Life

Min. 18 months if stored cool (< 25°C) and dry in closed original packing