Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Keynotes

- Resin-based water-soluble REL0 (Cleaned)

- Tier I Aerospace/Defense - ultra-low voiding

- Clear residue. Optimal viscosity. Excellent pin transfer. Suitable for CSP, QFN, LGA, etc

- World-class printability, instant activity response

- Superior dispensing or stencil printing

- Sharp definition at high-speeds

- Low solder balling and graping. Long stencil life

- Easy to clean using warm Deionized Water, IPA, solvents, water-based

Applications & Uses

- Applications

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Stencil Life (at 30 - 70% R/H & 20 - 25°C) | max. 12 | hours | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Viscosity

PRINT jar/cartridge DISPENSE syringe Tacky flux Tack force 200-275 100-140 20-50 30-37 * Malcom @ 10 RPM @ 25°C x10³ g/cm/s

- Printer Operations

Stencil printer does not require any specific optimization, should be fully adjustable based on standard in-house process requirements, including high-speed printers

Print Speed: 20-200 mm/sec (add pressure for speed)

Squeegee Pressure: 70-540 g/cm of blade (add for speed)

Stencil Vac/Wipe: Every 10-25 prints or as necessaryAutomated and vacuum cleaning systems for both stencil and misprinted boards. Manual cleaning using Isopropyl alcohol (IPA), co-solvents and/or ultrasonic scrubbers, vapor degreaser.

- Test Results

IPC-TM-650 Test Value Result Corrosion (Cleaned) 2.6.15 L: No corrosion PASS Copper Mirror (NC) 2.3.32 L: No breakthrough PASS ECM (Cleaned) 2.6.14.1 L: <1 decade drop PASS Quantitive Halides 2.3.28.1 L: <0.05% PASS SIR Test (Cleaned) 2.6.3.7 L: ≥100 MΩ PASS - Printing

Optimal print definition for fine pitch applications. Long stencil life of this product virtually eliminates waste of solder paste. For mesh/size determination refer to the Pitch Requirements chart below:

Size (micron) Type Value 75 - 45 μm T2 24 mil + 45 - 25 μm T3 16 - 24 mil 38 - 20 μm T4 12 - 16 mil 25 - 15 μm T5 < 12 mil 20 - 5 μm T6 < 8 mil - Sample Reflow Profile

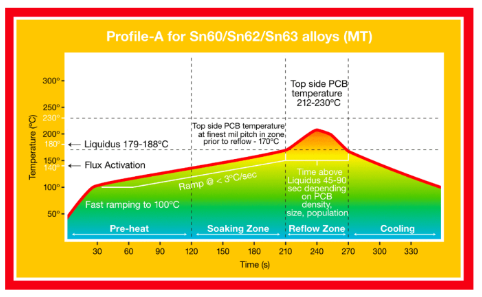

Mt° Profile-A can be used as a starting point for the leaded process optimization with Sn60, Sn62, Sn63 alloys. A cooldown rate of 2-4°C/sec is ideal for the formation of fine grain structure without risking damage to thermally sensitive components.

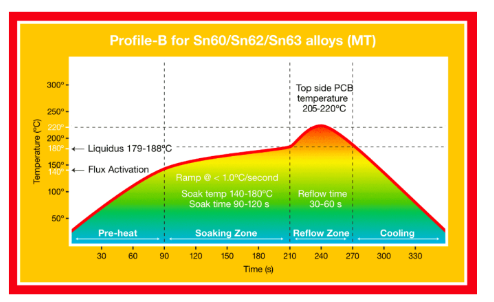

Mt° Profile-B is an alternative approach to solder Sn60, Sn62, Sn63 utilizing a soak of up to two minutes at 155°C may help to minimize voiding in leaded BGA, LGA & QFN assembles. This will allow more time for solvent components of the solder paste to outgas prior to reflow.

Packaging & Availability

- Packaging Type

- Availability

Hydra-MT™ - available in many alloys on request: Sn42Bi58, Sn42Bi57.6Ag0.4, Sn42Bi57Ag1, Sn43Pb43Bi14, Sn60Pb40, Sn62Pb36Ag2, Sn62.8Pb36.8Ag0.4, Sn63Pb37

- Packaging Information

Options with various viscosity and metal load for stencil printing and dispensing applications:

- Printing: Jars, 1/4 NPT nozzle cartridges

- Dispensing: Syringes, ProFlow cassettes

Storage & Handling

- Shelf Life, Storage, and Handling

Refrigerated storage at 5-7°C will prolong the solder paste shelf life to no less than 6 months. Solder Paste should be allowed to reach ambient temperature, normalize for about 6-8 hours before use. Tacky flux has 24 months shelf life stored in room temperature. Refrigeration won't extend shelf life. Normalize for 4-6 hours if stored refrigerated. Paste/flux in syringes and cartridges should be kept vertically, dispensing tip pointing down.

Note :NEVER FREEZE SOLDER PASTE / FLUX!