Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Color

- Physical Properties

- Processing Information (Injection Molding)

| Value | Units | Test Method / Conditions | |

| Density | 0.89 | g/cm³ | ISO 1183 |

| Melt Flow Rate (230°C/21.18 N) | 40.0 | g/10min | ISO 1133 |

| Tensile Modulus (100% Modulus, 500mm/min) | 7.0 | MPa | ISO 37 Type 1 |

| Tensile Strength (500mm/min) | 11.0 | MPa | ISO 37 Type 1 |

| Tensile Elongation (500mm/min) | 550.0 | % | ISO 37 Type 1 |

| Tear Strength | 60.0 | N/mm | ISO 34-B |

| Durometer Hardness (15 second delay) | 89.0 | Shore A | ASTM D2240 |

| Value | Units | Test Method / Conditions | |

| Nozzle Temperature | 370 - 470 | °F | — |

| Front Zone | 370 - 470 | °F | — |

| Middle Zone | 350 - 450 | °F | — |

| Rear Zone | 340 - 430 | °F | — |

| Mold Temperature | 70 - 120 | °F | — |

| Injection Speed | Fast | — | — |

| Screw RPM | Slow | — | — |

| Injection Pressure | 20% more than actual transfer pressure | — | — |

| Back Pressure | 50 - 100 | psi | — |

| Pack/Hold Pressure (of Injection Pressure) | 40 - 80 | % | — |

Technical Details & Test Data

- Test Results

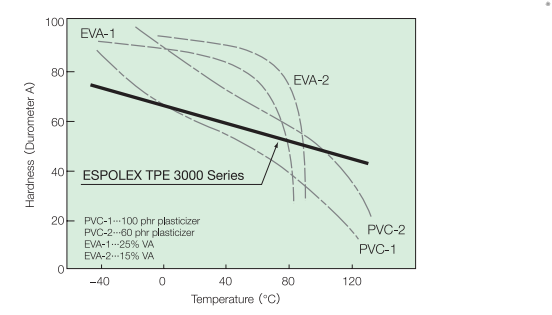

- Effect of Temperature on Hardness

Remarks:

Test method- ASTM D2240

Test specimen - Injection molded specimen

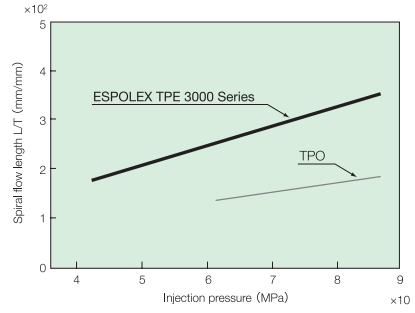

- Spiral Flow Characteristics (230°C)

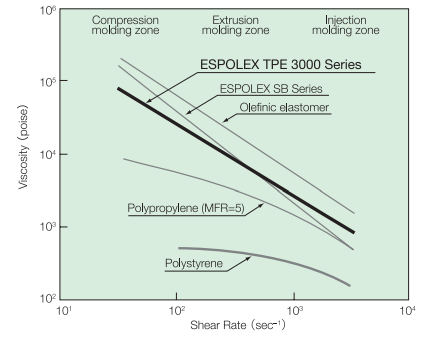

- Effect of Shear Rate on Viscosity (200°C)

The figure shows the relation between shear rate and viscosity of ESPOLEX TPE Series at 200°C in comparison with other thermoplastic resins and elastomers. Since its viscosity is dependent on shear rate, effective processing control can be achieved through the adjustment of injection pressure and injection speed.

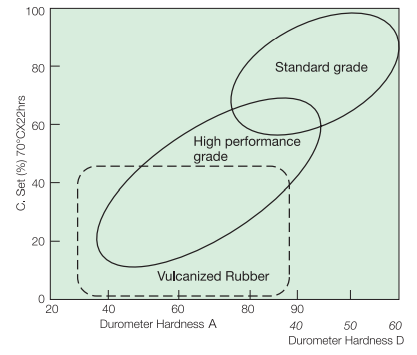

- Coverage of Hardness and Compression Set Values

- Tool Design Guidelines

Parameter Value Wall Thickness (WT) 2 – 4 mm Gate Type Fan Gate Gate Thickness (GT) 0.6 – 0.9 x WT Gate Width (GW) > 2 x GT Gate Land (GL) < 0.75 mm Runner Type Round Sprue “O” Diameter 3.5 x WT Main-Runner (SR) 2.5 x WT Secondary-Runner (MR) 1.5 x WT Draft 3 – 6 ° per side Inside Radius (IR) WT / 2 Outside Radius (OR) WT + IR Surface Texture Light Stipple Surface Coating Nickel / Teflon Vent Quantity 1 Every Inch Vent Depth 0.013 – 0.025 mm

Vent Width 5 mm