Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Industrial Additives Functions

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Cure Method

- Adhesive & Sealant Type

- Coating Type

- Applications

The principal uses are:

• Adhesives 1 component for manufacturing sandwich panel with PIR core (suggested quantity 70-120 g/m2)

• Adhesives 1 component for marine equipment

• Adhesives 2 components

• Primers for a wide range of substrates.

• One component PU coatings.

• Binder for mortar.

• Cement coatings with good chemical resistance

• Cured: 24 hours at 23ºC / 50% H.R

When SYNTHEL PE-3015 is used for mortars applications normally is in blend with quartz sand, in this case it is very important the relation between SYNTHEL PE-3015 and fillers (1:10, and 1:25 resin/ filler)- FINAL APPLICATION OF USE OF THE SYNTHEL PE-3015 IN MARINE EQUIPMENT

Synthel PE-3015 can be used as an adhesive according to item A1 / 3.18e of the Regulation (EU) 2017/306 in "Surfaces and coatings of flats with low flame propagation characteristics: adhesives used in the manufacture of class divisions" A "," B "and" C ".

Synthel PE-3015 complies with the reaction to fire according to the code PEF2010 Annex 1 Part5 as required by the Marine Equipment Directive 2014/90 / EU and its implementing regulation (EU) 2017/306 and thus confirms the number of 3259T17 report owned by

Synthesia Internacional, SLU in which it classifies that the Synthel PE-3015 meets the performance criteria for bulkhead, wall, ceiling, floor coverings and primary deck cladding coatings.

Conditions of Application.

▪ Ensure that the surface to be applied is clean, free of fat and dry. Apply on

the less porous face.

▪Apply an amount between 100-200 g / m2 extending homogeneously using

a brush or roller.

▪Drying and hardening of the adhesive occurs at ambient temperature after 24-48 hours depending

on the humidity. If you want to accelerate, you can add moisture by spraying water; approx. 20-40 g /m2

AENOR INTERNACIONAL acts as notified Body nº 0099 in the obtaining of module B "CE type examination" with certificate number B17 / 000008 and of module D "Conformity with the type based on quality assurance of the production process" with number of certificate B17 / 000009

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

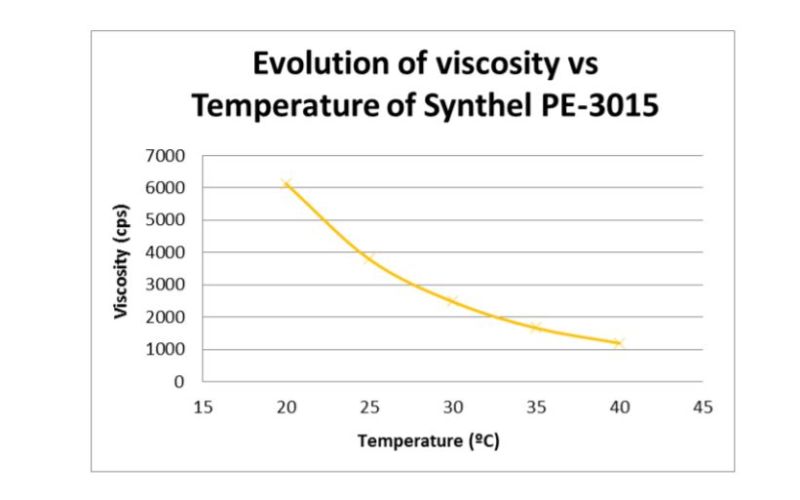

| Viscosity (25 °C) | 3000 - 5000 | mPa.s | — |

| Solid Content | 100 | % | — |

| NCO Contents (weight) | 16 ± 0,7 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- ADHESIVE FOR PANEL SANDWICH

Synthel PE-3015 adhesive is recognized by FM Approvals as a component in sandwich panel manufacturing for FM Approvals Class 4880. You can check its approval as an "Identified Component" at www.approvalguide.com

Technical Details & Test Data

- Evolution Of Viscosity vs Temperature

Storage & Handling

- Storage Recommendation

Store in a cool dry place, indoor and avoid unnecessary opening of containers. Avoid low temperatures which may cause precipitation of the product. SYNTHEL PE-3015 correctly stored, is perfectly maintained for more than 6 months

- Handling

Synthel PE-3015 should be used in well-ventilated area. Avoid inhaling vapors and protect skin and eyes from contact. In case of skin contact remove excess, wash with soap and water. For eyes contact, immediately flush with water for at least 15 minutes. If nose, throat or lungs become irritated from breathing in vapors, remove exposed person to fresh air