Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Chemical Resistance

Technical Details & Test Data

- Managing Temperatures

TECHNYL® BLUE, MANAGING TEMPERATURES FROM THE HIGHEST TO THE LOWEST

YOUR ENGINE GETS HOT ?

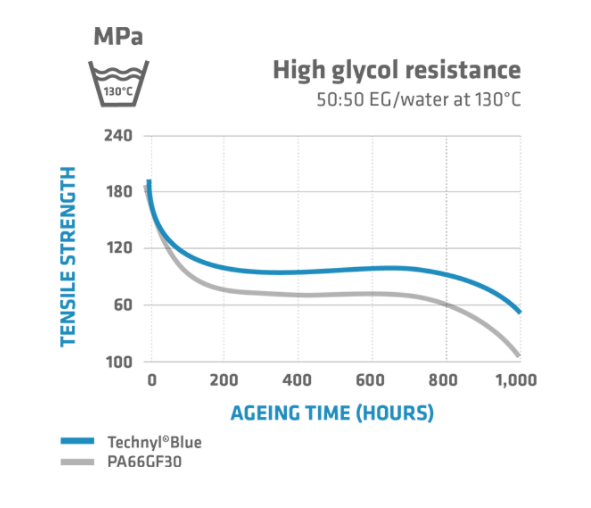

When you have to deal with high temperatures, Technyl® BLUE brings you a technology that provides your engine with a superior resistance to hot glycol.

WINTER IS COMING !

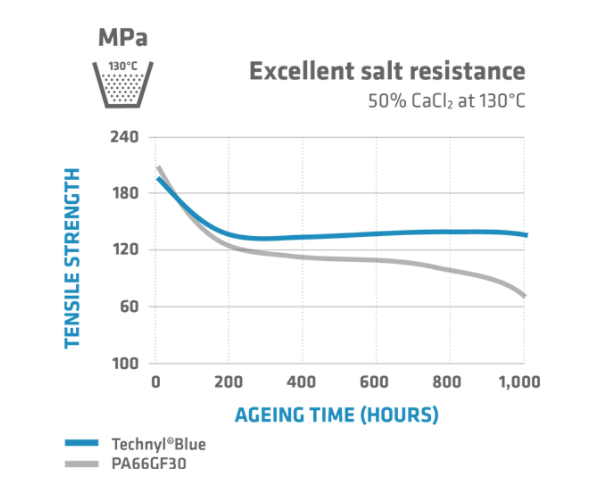

The top of the range Technyl® BLUE is a special compound highly resistant to road salts This material demonstrates high chemical resistance to calcium chloride, the preferred road salt used in countries with lower freezing temperatures.

- Thermal Management

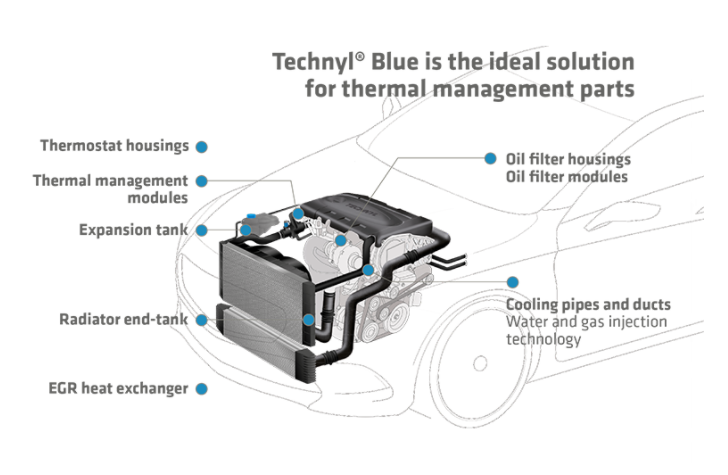

TECHNYL® BLUE IS THE IDEAL SOLUTION FOR THERMAL MANAGEMENT PARTS

With an attractive cost/performance ratio compared to metal or alternative plastics, Technyl® BLUE is one of the preferred solutions for thermal management in the automotive industry. After rigorous testing at OEMs and Tiers level, the material obtained full approval for use in parts such as radiator-end tanks, expansion tanks, electronic thermostat housing, oil filter housings/modules, kick connectors, cooling pipes and EGR heat exchangers.