Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Main Benefits

- Class-leading fire protection and electrical performance

- High mechanical strength

- Low moisture absorption and high dimensional stability

- Reduced production cost

- Key Features

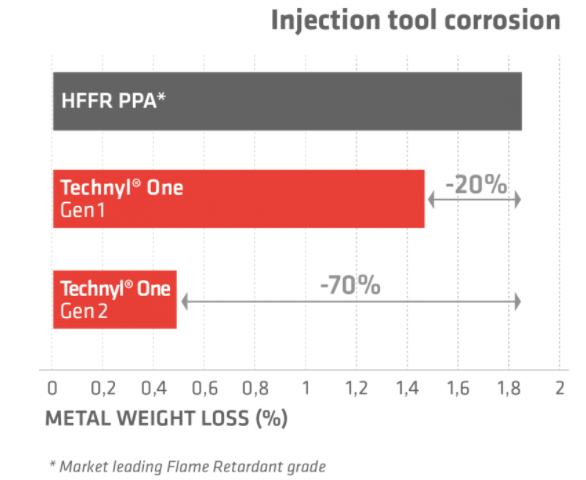

- Reduced corrosion of tools and injection molding machines

- Halogen-free flame retardant, non-flame retardant, and heat stabilized grades

- Unmatched thermal aging properties

- Full color sampling

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Technical Details & Test Data

- Injection tool corrosion

ADVANCED PLASTICS FOR TODAY’S DEMANDING NEEDS

Helps manufacturers push the limits of miniaturization in the industry, such as for electrical protection products, including mini circuit breakers, heavier-duty molded case circuit breakers, and contactors. With its wide processing window, accurate filling, and good surface aspect, it provides robust results without any drawbacks for tools and injection molding machines.

OPTIMIZED FOR POWER CONTROL EQUIPMENT

Offering a more effective solution than standard PA66, Technyl® G2 feature a patented polymer technology that yields unparalleled electrical performance with a composition that reduces tool corrosion and simplifies processing. Technyl® G2 meets production challenges by providing high flowability to reduce product wall thickness, along with UL-tested performance for electrical applications.